1490

Aluminum battery - a great addition to an electric vehicle

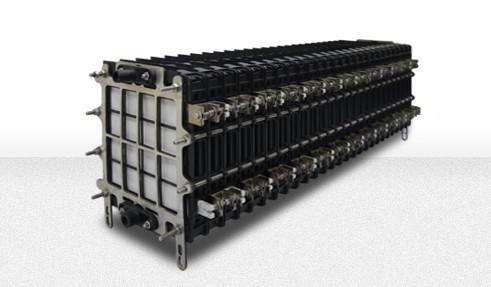

Company Phinergy first in the world has managed to produce aluminum air battery capable of operating in the car. 100-pound Al-Air battery contains enough energy to provide 3000 km running compact car. Phinergy technology has demonstrated a Citroen C1 and simplified version of the battery (50 plates, 500 g, in a housing filled with water). The car drove 1,800 kilometers on one charge, stopping only to replenish water - consumable electrolyte ( video ).

Aluminum does not replace the lithium-ion batteries (it does not charge from the wall), but perfectly complements them. After all, 95% of car trips makes for short distances, where sufficient standard batteries. Additional battery provides backup in case the battery is dead or if you need to travel far.

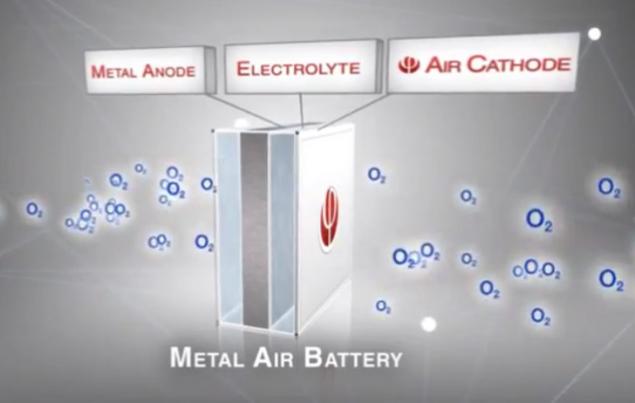

Air-Aluminium battery generates a current by a chemical reaction of the metal with oxygen from the ambient air. Aluminum plate - anode. On both sides of the cell is covered with a porous material with a silver catalyst that filters the CO 2 sub>. Metallic elements slowly degraded to Al (OH) 3 sub>.

The chemical formula of the reaction is as follows:

4 Al + 3 O 2 sub> + 6 H 2 sub> O = 4 Al (OH) 3 sub> + 2, 71

This is not some sensational novelty, and well-known technology. Her long been used by the military, because such elements provide extremely large energy density. But before the engineers could not manage to solve the problem with filtering CO 2 sub> and concomitant carbonation. Company Phinergy argues that solved the problem and already in 2017 can be made of aluminum batteries for electric vehicles (and not only for them).

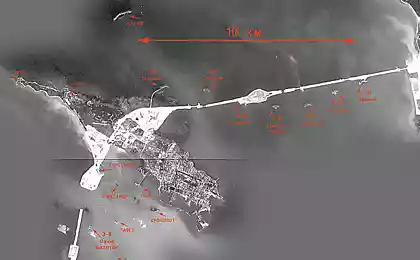

Lithium-ion batteries Tesla Model S weighs about 1,000 pounds and provide mileage of 500 km (in ideal conditions, the reality of 180-480 km). Say, if you cut them up to 900 kg and add aluminum battery, vehicle weight will not change. Cruising range on battery power will decrease by 10-20%, but the maximum mileage out of power increase right up to 3180-3480 km! You can drive from Moscow to Paris, and yet something remains.

In some ways this is similar to the concept of a hybrid car, but it does not require expensive and cumbersome internal combustion engine.

Lack of technology is obvious - the air-aluminum radiators have to change the service center. Maybe once a year or more. However, it is quite an ordinary procedure. The company Tesla Motors last year showed how batteries Model S me for 90 seconds ( amateur Video abbr>).

Other disadvantages - energy-intensive production, and possibly higher price. Production and processing of aluminum panels requires a large amount of energy. That is, from an environmental point of view, using them only increases the total electricity consumption in the whole economy. But consumption of more optimally distributed - it goes from big cities to remote areas with cheap energy, there are hydroelectric and steel plants.

Unknown, and how much would cost such batteries. Although the aluminum - cheap metal, but the cathode comprises an expensive silver. Phinergy not tell how it manufactures the patented catalyst. Perhaps this is a complex technical process.

But for all its faults of air-aluminum battery still seems very convenient addition to electric vehicles. At least as a temporary solution for the coming years (decades?), Until there is no problem of the battery capacity.

In Phinergy, meanwhile, are experimenting with "rechargeable» воздушно-цинковой battery . It generally works a thousand hours without special chemical degradation, since the oxidation of zinc - a reversible process.

Similar scientific developments underway in Russia .

Source: habrahabr.ru/post/226645/

Spacecraft Solar Probe Plus will go on record closer to the Sun.

Summary of the Soviet space exploration, types of rockets and the most significant victories in this field. Part 1