736

Iron Swallow global

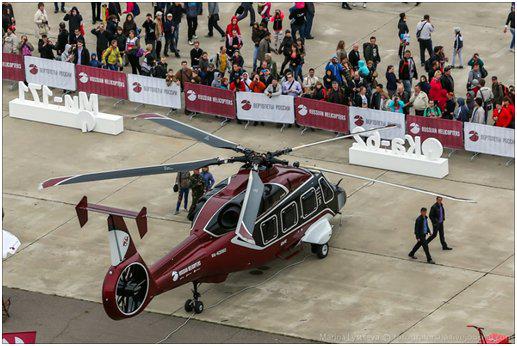

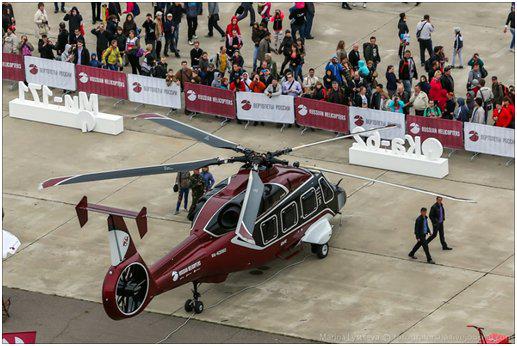

Take a closer look. Sleek and muscular unit. Lines are smooth, the design on top. And do you think that is? That's right - this is our new domestic multipurpose helicopter Ka-62! Certainly, many skeptics are now tightened as old as song: "Model, toy, this will not happen ever, futuristic concept cars, we also were, so what?". And that's what - in the next year will begin mass production of the long-awaited propeller unit, so the skeptics, it is better to be silent. While on the other hand they (skeptics) can also be understood, because the development of the Ka-62 was conducted already since the beginning of the 90's and many of them have never hoped to see firsthand a full copy of the helicopter. But this is the case when the "unfinished" is not synonymous with lack of demand. This project was supposed to lie down, go through several stages of adjustment to go through a number of improvements and all this in order to present to the public a new vehicle worthy of international recognition.

9 photo.

For the first time an experienced helicopter Ka 62 was demonstrated at the aerospace show MAKS-95 in Zhukovsky. It was assumed that the first helicopter flight will take place in 1996. Unfortunately, the Ka-62 was not meant to take off in the leap year. Perhaps it is even good. This was followed by years of silence, during which the work on the aircraft was carried out with varying degrees of intensity. And on May 17 the exhibition HeliRussia-2012 holding "Helicopters of Russia" presented to the public a car that is not only technically powerful instance created taking into account the latest world achievements of the aviation industry, but also the object catches the eye as industry professionals and ordinary people .

The basis of the development of the Ka-62 lay Ka-60, which originally was a military transport boat. In developing the new version of the aircraft, it was decided on the basis of the previous model to create a multi-purpose family of civil helicopters. Ka-62 can be used for the carriage of passengers with adequate comfort, cargo transportation inside the cabin and on the external sling, emergency medical care, perform rescue operations, conduct ice reconnaissance patrol and various operations, control of water borders, and more.

From the original Ka-60 Ka-62 civilian got the general scheme of the power plant and screws. Thus, these two helicopters were the first projects Design Bureau. Kamov, which have only one rotor and performed by the classical scheme. As the power plant in the early stages of the project proposed two turboshaft engine RD-600.

Of particular interest to the tail rotor helicopters. For the first time in domestic practice, he was imprisoned in the annular channel. In combination with a new design of the screw is significantly improves efficiency. This ultimately affects the cost of operation - tail rotor need less power, reducing fuel consumption. The second "mechanism" fuel economy is airframe. It has a drag-reducing lines and a mixed structure of a metal frame and trim composite parts. Composite materials make up almost 60% of the mass of the empty Ka-62.

If we continue the theme of "stuffing" opportunities and Ka-62, it is impossible not to note the helicopter load capacity, which is up to 2,500 kg on external sling or 15-16 passengers in the cabin. As already mentioned, on the basis of the Ka-62 developed sanitary and life options that differ with special equipment, including rescue hoist lifting capacity of 300 kg.

For export sales developed version of the Ka-62M, with a five-blade main rotor, foreign engines General Electric T700 / CT7-2D1 or LHTEC CT8-800 or Rolls-Royce / Turbomeca RTM 332 and navigation equipment company Bendix King.

The modern version of the Ka-62 for the Russian market kept outside the scheme and layout of the helicopter from the previous modifications, major changes affected the chassis and the engine compartment. Because instead of Russian turboshaft engines RD-600 are installed on the machine, French Turbomeca Ardiden 3G. Gearbox and transmission will deliver an Austrian company Zoerkler. The most important component of the helicopter - the chassis - are manufactured in Russia holding "Aircraft Equipment". Developed chassis allow for requirements for helicopter landing with high vertical speed, which in turn gives the potential to use them for use on ships. Recently, the holding company, opened its first engineering center in Russia for designing distributed systems of aircraft. With the establishment of this unit have the opportunity with the help of remote access to manage regional design offices, located on the grounds leading enterprises of the holding. In view of the optimization of the production of the idea of "becoming one of the main suppliers of landing systems for all types of helicopters and aircraft of Russian and foreign production" it looks quite realistic.

In conclusion I would like to say a couple of words about the Ka-62. This helicopter - a wonderful example of how the Russian design perfectly able to combine domestic achievements of engineering with the best "glands" of foreign production. All these components work together to create one of the best (if not the best) helicopter in its class. And all this is the result of the symbiosis of knowledge and developments. It is necessary to often exchange experiences and technological advances, once all this leads to such positive results is a pity that the world often forget about it.

9 photo.

For the first time an experienced helicopter Ka 62 was demonstrated at the aerospace show MAKS-95 in Zhukovsky. It was assumed that the first helicopter flight will take place in 1996. Unfortunately, the Ka-62 was not meant to take off in the leap year. Perhaps it is even good. This was followed by years of silence, during which the work on the aircraft was carried out with varying degrees of intensity. And on May 17 the exhibition HeliRussia-2012 holding "Helicopters of Russia" presented to the public a car that is not only technically powerful instance created taking into account the latest world achievements of the aviation industry, but also the object catches the eye as industry professionals and ordinary people .

The basis of the development of the Ka-62 lay Ka-60, which originally was a military transport boat. In developing the new version of the aircraft, it was decided on the basis of the previous model to create a multi-purpose family of civil helicopters. Ka-62 can be used for the carriage of passengers with adequate comfort, cargo transportation inside the cabin and on the external sling, emergency medical care, perform rescue operations, conduct ice reconnaissance patrol and various operations, control of water borders, and more.

From the original Ka-60 Ka-62 civilian got the general scheme of the power plant and screws. Thus, these two helicopters were the first projects Design Bureau. Kamov, which have only one rotor and performed by the classical scheme. As the power plant in the early stages of the project proposed two turboshaft engine RD-600.

Of particular interest to the tail rotor helicopters. For the first time in domestic practice, he was imprisoned in the annular channel. In combination with a new design of the screw is significantly improves efficiency. This ultimately affects the cost of operation - tail rotor need less power, reducing fuel consumption. The second "mechanism" fuel economy is airframe. It has a drag-reducing lines and a mixed structure of a metal frame and trim composite parts. Composite materials make up almost 60% of the mass of the empty Ka-62.

If we continue the theme of "stuffing" opportunities and Ka-62, it is impossible not to note the helicopter load capacity, which is up to 2,500 kg on external sling or 15-16 passengers in the cabin. As already mentioned, on the basis of the Ka-62 developed sanitary and life options that differ with special equipment, including rescue hoist lifting capacity of 300 kg.

For export sales developed version of the Ka-62M, with a five-blade main rotor, foreign engines General Electric T700 / CT7-2D1 or LHTEC CT8-800 or Rolls-Royce / Turbomeca RTM 332 and navigation equipment company Bendix King.

The modern version of the Ka-62 for the Russian market kept outside the scheme and layout of the helicopter from the previous modifications, major changes affected the chassis and the engine compartment. Because instead of Russian turboshaft engines RD-600 are installed on the machine, French Turbomeca Ardiden 3G. Gearbox and transmission will deliver an Austrian company Zoerkler. The most important component of the helicopter - the chassis - are manufactured in Russia holding "Aircraft Equipment". Developed chassis allow for requirements for helicopter landing with high vertical speed, which in turn gives the potential to use them for use on ships. Recently, the holding company, opened its first engineering center in Russia for designing distributed systems of aircraft. With the establishment of this unit have the opportunity with the help of remote access to manage regional design offices, located on the grounds leading enterprises of the holding. In view of the optimization of the production of the idea of "becoming one of the main suppliers of landing systems for all types of helicopters and aircraft of Russian and foreign production" it looks quite realistic.

In conclusion I would like to say a couple of words about the Ka-62. This helicopter - a wonderful example of how the Russian design perfectly able to combine domestic achievements of engineering with the best "glands" of foreign production. All these components work together to create one of the best (if not the best) helicopter in its class. And all this is the result of the symbiosis of knowledge and developments. It is necessary to often exchange experiences and technological advances, once all this leads to such positive results is a pity that the world often forget about it.