1056

Frying pan with your own hands

If you think a post about the construction, repair and manufacture things with their hands no longer surprise you, I suggest to follow a cat. The author of this post will tell you about the production of the pan in Chelyabinsk.

The fact is that at present rented accommodation, and want to buy kitchen utensils least. Razumeetsya- post is not about how to save money on buying a frying pan. Because if you calculate the spent material resources, as well as the time ... you get a very severe cost, which the budget can not be called. Therefore, let it be a story about technocratic humorous sketches. Boredom. For the love of ...

rukozhopstvu However, I have always aspired to a different life creative ideas. In addition, long time bathed in the blood of the heart, looking at both the landfill has sent hundreds of kilograms of usable rolled metal, stainless steel, aluminum.

Throw-known postulate of "Russian - never give up and never pay» ...

Why buy in the store for me was not a method. And if, for example, the jeans I come off the button, I was easier to do it from the copper itself, rather than shove it to the store to buy. (Of course, this refers to the time when I was on a business trip away from home. Because if I'm at home, engaged hyuney once, and there is no need.)

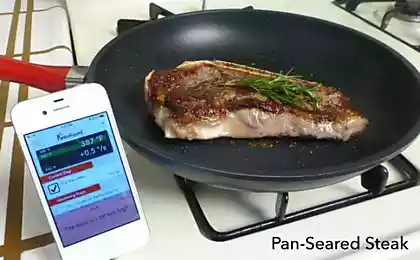

Catching preparing food, said that on the thin aluminum frying pan ketayskoy - one bullying. In the center of the temperature more ... Along the edges - lower. Temperature control on plite- hardly helps.

Therefore, for a long time thinking about making harsh pan with a thick bottom, which has a thermal inertia. Material - stainless steel. (Mark I do not remember it, but we know that for the repair of the fish factories and fishing boats to be used is not harmful to humans steel, because after a bad steel, no one will take the fish.)

At first the idea was to carve out a single piece of metal ... but bet the pros and cons ... decided it was best to collect two basic elements, that is, construction will be welded. As that:

Round pancake thickness of 15mm and height of 30mm ring. Damn it is the bottom and out of the ring will turn the rim pans. These two elements decided to cook. Next, get konstruktsiyu- grind lathe ... To illustrate the ideas attach rukozhop.

Thus, the manufacturing process is as follows:

It is welded to the ring ... technological quality and beauty of welding is not required here, because it will then be cut.

For this damn ring fastened to the lathe chuck and process the contact surface to the ring. And also sharpen chamfer to weld.

Fortunately there was a ring of stainless steel desired diametra- little more than a pancake.

Turned damn ... not in the sense of "to grind, damn it !!" ... namely pancake machine grinds on.

Ring just grind.

to fit and weld with a pancake ...

These two elements - ready for welding together.

SO! Fill the weld argon welding with tungsten electrode doped by wire. In short - weld. There is already a requirement for welding higher ...

Next, prepare the other process ring- to consolidate all this Baida on the other hand ... in the cartridge.

Welded. Here resembling welding quality - only to temporarily keep the item in the chuck of a lathe. Therefore, we cook quickly, almost clumsy. However, it is safe. :)

We set all this kotovassiyu eat through the machine and the inner surface of the base on which to align the whole structure.

Overturn, and has obtained eat through the surface of the other ring attachment.

So we got two coaxial securing base pans that will allow us to grind it from different sides and not to lose the alignment of the outer and inner surface of the pan.

From the ceiling ... I chose the angle of the walls of the pans 13 degrees ...

Expand support on this angle.

Thus the tool can move along the path, which will cause the desired shape pans.

at an angle of 13 gr. We grind the weld flush.

Temporarily ... immediately on the machine, cut off the ring cutter process ... and eat through the bottom of the pans.

Then again, it welds :)

Is mounted on a structure,

to the machine and process we have an internal cavity.

Drove quite a lot of metal in the chip, but for the utilization of the material we are not looking ... Anyway, it all goes to the smelter.

Earlier in the Soviet Union told us stories about what & quot; ... they say abroad is brought to the coefficient unit ... & quot;

But this was not always true ... now I know exactly dont.gif

For it is only in our stainless steel was put only on the commissar ...

they have the same water was always full and there are copper and stainless steel ...

and we have only recently switched to metal and plastic, and are glad that is over with eplya CHERMET ...

Already received something like that. ...

But then I decided to postpone the work until later ...

and at the same time to make the ears of the pan bar. Weld decided to advance until thick wall ... just in case

This is what happens ... with ears already looks good

but as yet the thick walls ... need to drive ...

For the remainder of technological ring fasten the pan clean and grind the final profile.

SKINS little sandpaper ...

Although stainless steel cutter comes out of and so smooth ...

Then cut off the Bulgarian welded, welded support ring ... and a bit of grind,

without fanaticism, but ... for me personally lower side aesthetically never interested.

That's actually what we did:

The wall thickness of approximately 4mm, the thickness of the bottom 8 mm. Few in Chelyabinsk, too heavy ... but remind !, I expected from pans thermal inertia ... because it's easier to fry food.

Ears I made from Ø5 mm bar and to my pleasant surprise, they do not heat up with a frying pan. That is, you can keep hvatat- bare hands. Hooray! and they are quite durable.

Source: vistador

--img24--

Source:

The fact is that at present rented accommodation, and want to buy kitchen utensils least. Razumeetsya- post is not about how to save money on buying a frying pan. Because if you calculate the spent material resources, as well as the time ... you get a very severe cost, which the budget can not be called. Therefore, let it be a story about technocratic humorous sketches. Boredom. For the love of ...

rukozhopstvu However, I have always aspired to a different life creative ideas. In addition, long time bathed in the blood of the heart, looking at both the landfill has sent hundreds of kilograms of usable rolled metal, stainless steel, aluminum.

Throw-known postulate of "Russian - never give up and never pay» ...

Why buy in the store for me was not a method. And if, for example, the jeans I come off the button, I was easier to do it from the copper itself, rather than shove it to the store to buy. (Of course, this refers to the time when I was on a business trip away from home. Because if I'm at home, engaged hyuney once, and there is no need.)

Catching preparing food, said that on the thin aluminum frying pan ketayskoy - one bullying. In the center of the temperature more ... Along the edges - lower. Temperature control on plite- hardly helps.

Therefore, for a long time thinking about making harsh pan with a thick bottom, which has a thermal inertia. Material - stainless steel. (Mark I do not remember it, but we know that for the repair of the fish factories and fishing boats to be used is not harmful to humans steel, because after a bad steel, no one will take the fish.)

At first the idea was to carve out a single piece of metal ... but bet the pros and cons ... decided it was best to collect two basic elements, that is, construction will be welded. As that:

Round pancake thickness of 15mm and height of 30mm ring. Damn it is the bottom and out of the ring will turn the rim pans. These two elements decided to cook. Next, get konstruktsiyu- grind lathe ... To illustrate the ideas attach rukozhop.

Thus, the manufacturing process is as follows:

It is welded to the ring ... technological quality and beauty of welding is not required here, because it will then be cut.

For this damn ring fastened to the lathe chuck and process the contact surface to the ring. And also sharpen chamfer to weld.

Fortunately there was a ring of stainless steel desired diametra- little more than a pancake.

Turned damn ... not in the sense of "to grind, damn it !!" ... namely pancake machine grinds on.

Ring just grind.

to fit and weld with a pancake ...

These two elements - ready for welding together.

SO! Fill the weld argon welding with tungsten electrode doped by wire. In short - weld. There is already a requirement for welding higher ...

Next, prepare the other process ring- to consolidate all this Baida on the other hand ... in the cartridge.

Welded. Here resembling welding quality - only to temporarily keep the item in the chuck of a lathe. Therefore, we cook quickly, almost clumsy. However, it is safe. :)

We set all this kotovassiyu eat through the machine and the inner surface of the base on which to align the whole structure.

Overturn, and has obtained eat through the surface of the other ring attachment.

So we got two coaxial securing base pans that will allow us to grind it from different sides and not to lose the alignment of the outer and inner surface of the pan.

From the ceiling ... I chose the angle of the walls of the pans 13 degrees ...

Expand support on this angle.

Thus the tool can move along the path, which will cause the desired shape pans.

at an angle of 13 gr. We grind the weld flush.

Temporarily ... immediately on the machine, cut off the ring cutter process ... and eat through the bottom of the pans.

Then again, it welds :)

Is mounted on a structure,

to the machine and process we have an internal cavity.

Drove quite a lot of metal in the chip, but for the utilization of the material we are not looking ... Anyway, it all goes to the smelter.

Earlier in the Soviet Union told us stories about what & quot; ... they say abroad is brought to the coefficient unit ... & quot;

But this was not always true ... now I know exactly dont.gif

For it is only in our stainless steel was put only on the commissar ...

they have the same water was always full and there are copper and stainless steel ...

and we have only recently switched to metal and plastic, and are glad that is over with eplya CHERMET ...

Already received something like that. ...

But then I decided to postpone the work until later ...

and at the same time to make the ears of the pan bar. Weld decided to advance until thick wall ... just in case

This is what happens ... with ears already looks good

but as yet the thick walls ... need to drive ...

For the remainder of technological ring fasten the pan clean and grind the final profile.

SKINS little sandpaper ...

Although stainless steel cutter comes out of and so smooth ...

Then cut off the Bulgarian welded, welded support ring ... and a bit of grind,

without fanaticism, but ... for me personally lower side aesthetically never interested.

That's actually what we did:

The wall thickness of approximately 4mm, the thickness of the bottom 8 mm. Few in Chelyabinsk, too heavy ... but remind !, I expected from pans thermal inertia ... because it's easier to fry food.

Ears I made from Ø5 mm bar and to my pleasant surprise, they do not heat up with a frying pan. That is, you can keep hvatat- bare hands. Hooray! and they are quite durable.

Source: vistador

--img24--

Source: