3477

Damask maker

Gold shines finish my dagger;

Blade reliable, without blemish;

Bulat keeps his mysterious temper,

The heritage brane east.

MY Lermontov "The Poet»

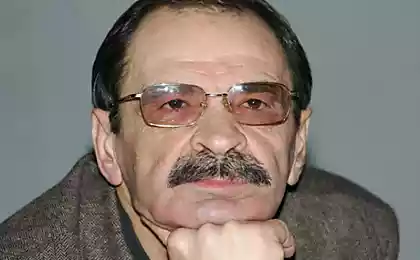

Ilia Kulik - known among gunsmiths Yaroslavl blacksmith. Nowadays blacksmith surprise anyone is difficult, but that it may be interesting, I would say that it unusual blacksmith. This is not a craftsman, but a real Master jokingly makes a startling beauty of things made of damask and Damascus steel.

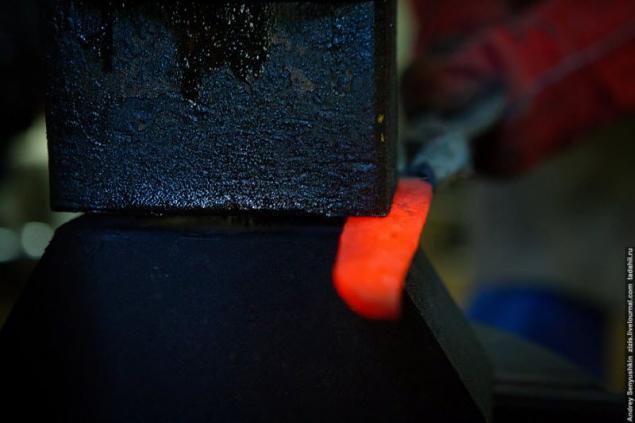

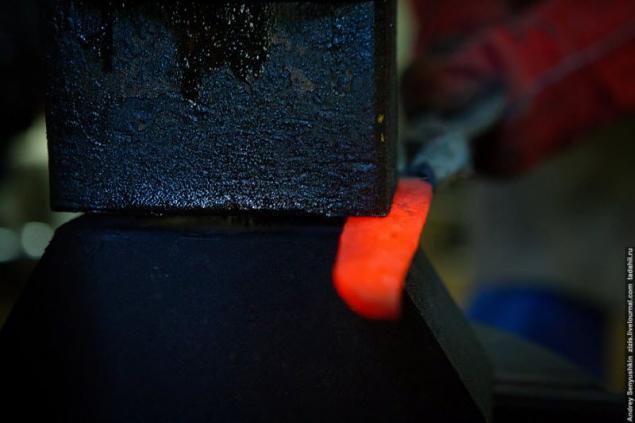

And Bulat and Damascus is very close in spirit heterogeneous beautiful steel. Damascus is obtained by tying up several plates of different metals. Taken several thin plates and repeatedly prokovyvayutsya, mixed metals and turns Damascus. Damascus steel cook. In the composition and proportions of the alloy and is one of the secrets of this metal. The photo is just bullion Damascus steel, we can say only that from the crucible.

During cooking, every detail is important, the alloy must be cooked, but not be perederzhanym on fire, salt and pepper to taste. What happens next depends on the preference of the wizard. Someone prefers unfetters entire ingot, someone cut it along or across, this will depend on the future pattern and strength of the blade. Ilya prefers to cut into four parts, like an orange.

Bullion metal pattern resembles cut wood, just circles. This pattern very few people interested, so the correctness pull the shoes is not only strength, but also the future pattern of veins.

Do you think Elijah will show us some secrets? Of course not, we will train on the water pipes! This, of course, a joke. The pipe is welded at the initial stage for the convenience of grip.

Damascus steel has come to us from India, where people can meditate for decades or years to make one sword. The old Hindu smiths and hammers more on the hammers were like, and time seems to have been more.

Our blacksmiths work actively used apprentices. Master knew where to strike, the student was able to keep a sledgehammer. This antiquated method significantly reduces the time of manufacture, but it still was not very fast.

The aid of modern blacksmiths comes sledgehammer. In times of Anosov, the godfather of the Russian Bulat, it was a huge steam colossus. Almost like a chimney, only louder. Now blacksmiths in premium remaining after the liquidation of the Soviet factories pneumatic hammers. Not so exciting imagination as steam, but no less productive.

Several heat, several approaches and quartered Damascus steel is transformed into a rectangular plate-blank. Manually on this action will take half a day, mechanized way ten or fifteen minutes. And the ancient Hindus more than one day.

What I liked Ilya, it's humor and work with the details. Many blacksmiths to put it mildly, trash, not prokovyvaya invisible eye space, if not "save" the metal by welding instead shank bolts and nails. And that, he's still in the grip, no one will see.

It's all to be honest. Be sure that the knife from Kulikova made on the conscience and the secret "stocks" is not there. By the way, thanks to Ilya for educational program when I was recently in the production of blades in Zlatoust, some issues still put people into a dead end

About Zlatoust craftsmen I have more to say, it was there in the beginning of the XIX century Pavel Petrovich Anosov launched commercial production of cast Damascus steel for the Russian army.

When you pull the shoes smith knows which side will be cutting and what will be the butt. Make the other side of the edge, which was foreign in the ingot. Please note: along the blade is as though crack. In fact, this "skhlopnuvshayasya" outer wall of the ingot.

One question that arises is why Bulat, who at the beginning of the last century to produce hundreds of tons and about which is composed of many poems and tales, why it has become so rare in today's world? The fact that there is now a huge number of highly specialized alloys, easier to manufacture, cheaper and less whimsical. But the combined properties of appreciating the manufacture of knives, Damascus steel remains to this day one of the leaders.

In addition, the manufacture of the blade of a "samovar" became a blacksmith puts a product not only skill, but also a bit of the soul, and the blade, in turn, can surprise even its creator

Why is it that Damascus steel Damascus and unique features? All the matter in the inhomogeneity of the alloy. Metal with low carbon content is softer, High-contrast, firmer and better sharpen. When you pull the shoes and Damascus steel Damascus these kinds of metals are mixed and maintain a beautiful pattern of lines. After quenching the blade and acquires strength and flexibility simultaneously. In addition, such fine steel holds an edge - a soft metal grinds, and high-carbon creates cutting edge of small, not distinct eye teeth.

Of course the myths about the magic power of Damascus steel is not more than myths. Damask sword was the sword-kladentsom, cutting armor like butter. Moreover, many historians doubt the correctness of the name Damascus steel.

Damascus has never been a blacksmith, or metallurgical center. It was a huge market, which have been gathered items for sale from the east to the west. Bulat and Damascus was made in Syria, Persia and India, and in Damascus just sold.

And the quality of medieval products, according to Elias, is not very impressive. There are isolated instances, which are exhibited in museums and in the vaults are tons damask consumer goods, which actually fought.

It is clear that such a time-consuming process using manual labor could not affect the quality. After all needed huge amounts of relatively inexpensive and reliable weapons and minor tweaks eyes closed.

Ilya knives do not hurry, as I said, with attention to detail and in a good meticulously. In recent years, very rarely taken for exclusive things, often making an already proven model.

This approach is explained very simply. To make an exclusive reliable and satisfying the requirements of damask knife time and effort necessary to spend as much as on the production of several tested models.

Of course this does not mean that Elijah makes two or three kinds of knives and everything. He always some ideas, some new types of blades in the work, some with friends in a "test drive." In this approach, each blade about it can be said that guarantees its quality.

While svezhevykovannoy blade cools down and waits for further processing, see Damascus. And Damascus, and damask is not the name of a particular alloy, but rather the name of the process by which the alloy is obtained. The bar is on the left Damascus three soft metal that is used in the manufacture of sticks. By the way, the handle also makes Ilya himself. Previously, it was engaged cabinetmaker, but "if you want good - do it yourself".

On the right bar of meteoritic metal. It really was once a meteorite, a very rare and difficult in the smelting and processing of metals.

The world's only meteor knife. The inner layer of Damascus steel, and the outer layers of the meteorite. View yet ugly, yes to it and experimental

The next step is grinding and rough grinding on emery tape. Theoretically possible to forge a blade almost perfect, there will be only sand, but it's too long. Besides the removal of the metal layer on the sides adds original drawings Damascus steel.

Though in the smithy and no chief engineer, but health is given due attention. Still, it is one and the, and blacksmithing considered for light one of the most harmful.

So, with jokes and rhymes, almost new born knife. We are not seeing the brewing process Damascus steel, and not see the hardening process, but there's better not to disturb the Master.

Here in brief is that we have seen: Damascus steel ingot, quarters, plate-blank, to forge the blade, the blade after the initial stripping and coarse blade, hardened and prepared for polishing.

Says Ilya, customer prefabricated better not to show, and give a ready knife. In some ways I agree with him

But even without hardening it can be used as a glass cutter. Hussars?

My daughter got a real guardian of the hands of the blacksmith - a real forged nails! Lisychu gift like

Our blade is still blank, it remains to be hardening, grinding, etching, grinding. Course will be pretty functional handle and sheath. And loving, appreciating the host. Otherwise, why?

If you want to buy a good knife or read interesting articles about blacksmithing and damask steel, welcome to the site of Elijah Kulikova bestbulat.ru. And there are pictures of his best works, such as this here "Bukhara".

Source: zizis.livejournal.com

Blade reliable, without blemish;

Bulat keeps his mysterious temper,

The heritage brane east.

MY Lermontov "The Poet»

Ilia Kulik - known among gunsmiths Yaroslavl blacksmith. Nowadays blacksmith surprise anyone is difficult, but that it may be interesting, I would say that it unusual blacksmith. This is not a craftsman, but a real Master jokingly makes a startling beauty of things made of damask and Damascus steel.

And Bulat and Damascus is very close in spirit heterogeneous beautiful steel. Damascus is obtained by tying up several plates of different metals. Taken several thin plates and repeatedly prokovyvayutsya, mixed metals and turns Damascus. Damascus steel cook. In the composition and proportions of the alloy and is one of the secrets of this metal. The photo is just bullion Damascus steel, we can say only that from the crucible.

During cooking, every detail is important, the alloy must be cooked, but not be perederzhanym on fire, salt and pepper to taste. What happens next depends on the preference of the wizard. Someone prefers unfetters entire ingot, someone cut it along or across, this will depend on the future pattern and strength of the blade. Ilya prefers to cut into four parts, like an orange.

Bullion metal pattern resembles cut wood, just circles. This pattern very few people interested, so the correctness pull the shoes is not only strength, but also the future pattern of veins.

Do you think Elijah will show us some secrets? Of course not, we will train on the water pipes! This, of course, a joke. The pipe is welded at the initial stage for the convenience of grip.

Damascus steel has come to us from India, where people can meditate for decades or years to make one sword. The old Hindu smiths and hammers more on the hammers were like, and time seems to have been more.

Our blacksmiths work actively used apprentices. Master knew where to strike, the student was able to keep a sledgehammer. This antiquated method significantly reduces the time of manufacture, but it still was not very fast.

The aid of modern blacksmiths comes sledgehammer. In times of Anosov, the godfather of the Russian Bulat, it was a huge steam colossus. Almost like a chimney, only louder. Now blacksmiths in premium remaining after the liquidation of the Soviet factories pneumatic hammers. Not so exciting imagination as steam, but no less productive.

Several heat, several approaches and quartered Damascus steel is transformed into a rectangular plate-blank. Manually on this action will take half a day, mechanized way ten or fifteen minutes. And the ancient Hindus more than one day.

What I liked Ilya, it's humor and work with the details. Many blacksmiths to put it mildly, trash, not prokovyvaya invisible eye space, if not "save" the metal by welding instead shank bolts and nails. And that, he's still in the grip, no one will see.

It's all to be honest. Be sure that the knife from Kulikova made on the conscience and the secret "stocks" is not there. By the way, thanks to Ilya for educational program when I was recently in the production of blades in Zlatoust, some issues still put people into a dead end

About Zlatoust craftsmen I have more to say, it was there in the beginning of the XIX century Pavel Petrovich Anosov launched commercial production of cast Damascus steel for the Russian army.

When you pull the shoes smith knows which side will be cutting and what will be the butt. Make the other side of the edge, which was foreign in the ingot. Please note: along the blade is as though crack. In fact, this "skhlopnuvshayasya" outer wall of the ingot.

One question that arises is why Bulat, who at the beginning of the last century to produce hundreds of tons and about which is composed of many poems and tales, why it has become so rare in today's world? The fact that there is now a huge number of highly specialized alloys, easier to manufacture, cheaper and less whimsical. But the combined properties of appreciating the manufacture of knives, Damascus steel remains to this day one of the leaders.

In addition, the manufacture of the blade of a "samovar" became a blacksmith puts a product not only skill, but also a bit of the soul, and the blade, in turn, can surprise even its creator

Why is it that Damascus steel Damascus and unique features? All the matter in the inhomogeneity of the alloy. Metal with low carbon content is softer, High-contrast, firmer and better sharpen. When you pull the shoes and Damascus steel Damascus these kinds of metals are mixed and maintain a beautiful pattern of lines. After quenching the blade and acquires strength and flexibility simultaneously. In addition, such fine steel holds an edge - a soft metal grinds, and high-carbon creates cutting edge of small, not distinct eye teeth.

Of course the myths about the magic power of Damascus steel is not more than myths. Damask sword was the sword-kladentsom, cutting armor like butter. Moreover, many historians doubt the correctness of the name Damascus steel.

Damascus has never been a blacksmith, or metallurgical center. It was a huge market, which have been gathered items for sale from the east to the west. Bulat and Damascus was made in Syria, Persia and India, and in Damascus just sold.

And the quality of medieval products, according to Elias, is not very impressive. There are isolated instances, which are exhibited in museums and in the vaults are tons damask consumer goods, which actually fought.

It is clear that such a time-consuming process using manual labor could not affect the quality. After all needed huge amounts of relatively inexpensive and reliable weapons and minor tweaks eyes closed.

Ilya knives do not hurry, as I said, with attention to detail and in a good meticulously. In recent years, very rarely taken for exclusive things, often making an already proven model.

This approach is explained very simply. To make an exclusive reliable and satisfying the requirements of damask knife time and effort necessary to spend as much as on the production of several tested models.

Of course this does not mean that Elijah makes two or three kinds of knives and everything. He always some ideas, some new types of blades in the work, some with friends in a "test drive." In this approach, each blade about it can be said that guarantees its quality.

While svezhevykovannoy blade cools down and waits for further processing, see Damascus. And Damascus, and damask is not the name of a particular alloy, but rather the name of the process by which the alloy is obtained. The bar is on the left Damascus three soft metal that is used in the manufacture of sticks. By the way, the handle also makes Ilya himself. Previously, it was engaged cabinetmaker, but "if you want good - do it yourself".

On the right bar of meteoritic metal. It really was once a meteorite, a very rare and difficult in the smelting and processing of metals.

The world's only meteor knife. The inner layer of Damascus steel, and the outer layers of the meteorite. View yet ugly, yes to it and experimental

The next step is grinding and rough grinding on emery tape. Theoretically possible to forge a blade almost perfect, there will be only sand, but it's too long. Besides the removal of the metal layer on the sides adds original drawings Damascus steel.

Though in the smithy and no chief engineer, but health is given due attention. Still, it is one and the, and blacksmithing considered for light one of the most harmful.

So, with jokes and rhymes, almost new born knife. We are not seeing the brewing process Damascus steel, and not see the hardening process, but there's better not to disturb the Master.

Here in brief is that we have seen: Damascus steel ingot, quarters, plate-blank, to forge the blade, the blade after the initial stripping and coarse blade, hardened and prepared for polishing.

Says Ilya, customer prefabricated better not to show, and give a ready knife. In some ways I agree with him

But even without hardening it can be used as a glass cutter. Hussars?

My daughter got a real guardian of the hands of the blacksmith - a real forged nails! Lisychu gift like

Our blade is still blank, it remains to be hardening, grinding, etching, grinding. Course will be pretty functional handle and sheath. And loving, appreciating the host. Otherwise, why?

If you want to buy a good knife or read interesting articles about blacksmithing and damask steel, welcome to the site of Elijah Kulikova bestbulat.ru. And there are pictures of his best works, such as this here "Bukhara".

Source: zizis.livejournal.com