618

Long way to the ring

For decades, the company «Tiffany & Co.» Buy only pre-cut and polished diamonds from suppliers. However, during the rise of the industry to own a business for the production of diamonds is not so simple. Now, the New York-based company buys rough diamonds, which are sent to the factories of the subsidiary «Laurelton Diamonds». Collected here are photos from the Belgian office of the company «Laurelton Diamonds», which opened in 2002.

11 photos via bigpicture

1. Head of a magnifying glass on the neck waiting for the supply of rough diamonds in the department «Laurelton Diamonds» company «Tiffany & Co.» in Antwerp, Belgium. (Pierre Terdjman / Gamma for The Wall Street Journal)

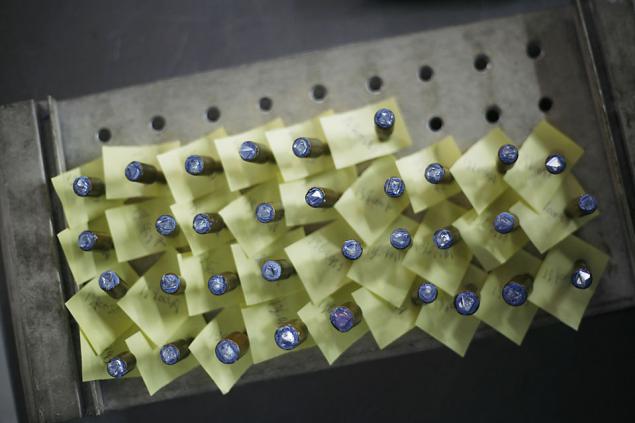

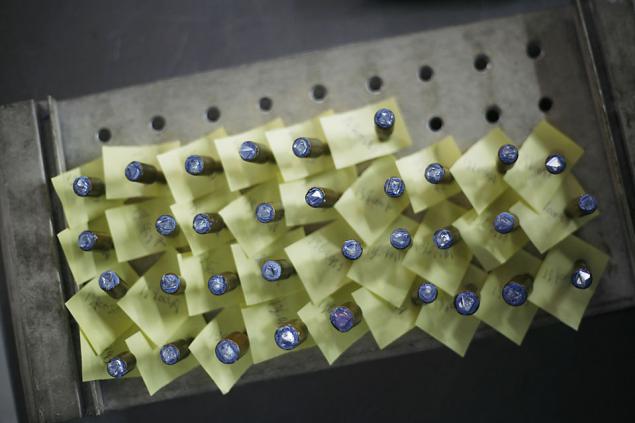

2. Diamonds with ink inscriptions indicating their incisions, placed in copper clips with some of the plaster and glue. Hot plate helps plaster to harden. (Pierre Terdjman / Gamma for The Wall Street Journal)

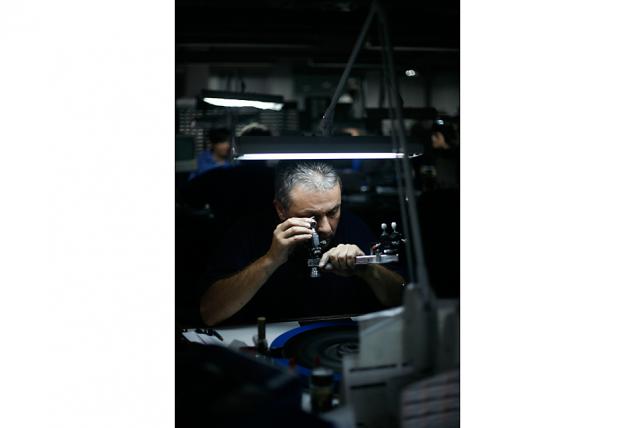

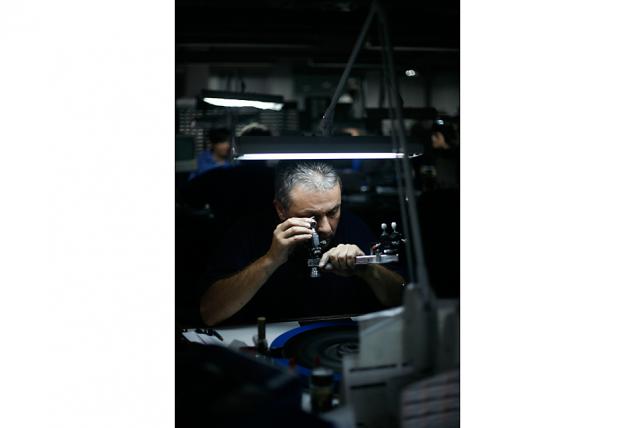

3. Work of the grinding wheel exploring the line that he cut in the diamond at the company «Laurelton Diamonds» in Antwerp, Belgium. (Pierre Terdjman / Gamma for The Wall Street Journal)

4. Work explores just arrived raw material in the company «Laurelton Diamonds» in Antwerp, Belgium. (Pierre Terdjman / Gamma for The Wall Street Journal)

5. A team of experienced polishers working on the stones of his grinding wheel «Tiffany & Co. Laurelton Diamonds »in Antwerp. (Pierre Terdjman / Gamma for The Wall Street Journal)

6. Experienced grinder working on a stone on the grinding wheel in the office of «Tiffany & Co. Laurelton Di "monds» Antwerp. (Pierre Terdjman / Gamma for The Wall Street Journal)

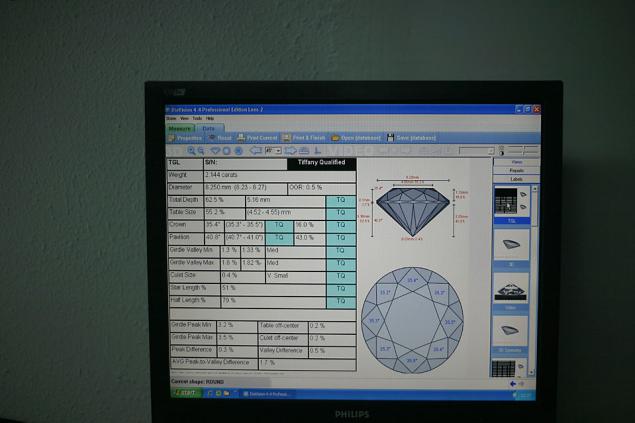

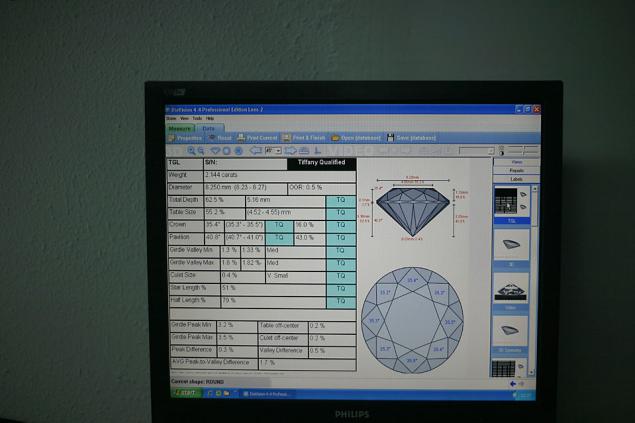

7. With the help of new technology workers «Tiffany & Co.» can see the flaws in the rough diamond. The company «Laurelton Diamonds» in Antwerp computers help to establish the most favorable ratio of size and shape of the finished stone still in the raw feed material. (Pierre Terdjman / Gamma for The Wall Street Journal)

8. A woman working for a powerful microscope in the department for cutting diamonds companies «Tiffany & Co. Laurelton Diamonds »in Antwerp. (Pierre Terdjman / Gamma for The Wall Street Journal)

9. A computerized review of the completed diamond in the office of «Laurelton Diamonds» in Antwerp. Computers help to determine whether the proportion satisfy the technical data of each face of the seller. This diamond is approved by «Tiffany» 11 criteria. (Pierre Terdjman / Gamma for The Wall Street Journal)

10. Almost at every stage of the process of handling and clipping employees «Laurelton Diamond» look at the diamond into a magnifying glass. (Pierre Terdjman / Gamma for The Wall Street Journal)

11. The finished diamond is illuminated by light from the microscope in «Tiffany & Co. Laurelton Diamond »in Antwerp. (Pierre Terdjman / Gamma for The Wall Street Journal)

Source:

11 photos via bigpicture

1. Head of a magnifying glass on the neck waiting for the supply of rough diamonds in the department «Laurelton Diamonds» company «Tiffany & Co.» in Antwerp, Belgium. (Pierre Terdjman / Gamma for The Wall Street Journal)

2. Diamonds with ink inscriptions indicating their incisions, placed in copper clips with some of the plaster and glue. Hot plate helps plaster to harden. (Pierre Terdjman / Gamma for The Wall Street Journal)

3. Work of the grinding wheel exploring the line that he cut in the diamond at the company «Laurelton Diamonds» in Antwerp, Belgium. (Pierre Terdjman / Gamma for The Wall Street Journal)

4. Work explores just arrived raw material in the company «Laurelton Diamonds» in Antwerp, Belgium. (Pierre Terdjman / Gamma for The Wall Street Journal)

5. A team of experienced polishers working on the stones of his grinding wheel «Tiffany & Co. Laurelton Diamonds »in Antwerp. (Pierre Terdjman / Gamma for The Wall Street Journal)

6. Experienced grinder working on a stone on the grinding wheel in the office of «Tiffany & Co. Laurelton Di "monds» Antwerp. (Pierre Terdjman / Gamma for The Wall Street Journal)

7. With the help of new technology workers «Tiffany & Co.» can see the flaws in the rough diamond. The company «Laurelton Diamonds» in Antwerp computers help to establish the most favorable ratio of size and shape of the finished stone still in the raw feed material. (Pierre Terdjman / Gamma for The Wall Street Journal)

8. A woman working for a powerful microscope in the department for cutting diamonds companies «Tiffany & Co. Laurelton Diamonds »in Antwerp. (Pierre Terdjman / Gamma for The Wall Street Journal)

9. A computerized review of the completed diamond in the office of «Laurelton Diamonds» in Antwerp. Computers help to determine whether the proportion satisfy the technical data of each face of the seller. This diamond is approved by «Tiffany» 11 criteria. (Pierre Terdjman / Gamma for The Wall Street Journal)

10. Almost at every stage of the process of handling and clipping employees «Laurelton Diamond» look at the diamond into a magnifying glass. (Pierre Terdjman / Gamma for The Wall Street Journal)

11. The finished diamond is illuminated by light from the microscope in «Tiffany & Co. Laurelton Diamond »in Antwerp. (Pierre Terdjman / Gamma for The Wall Street Journal)

Source: