836

Excursion to the largest English-brewery

He writes to the community photos ternovskiy photo_discovery

I love ale. It is much more aromatic lager (usually light beer, to which we are accustomed to), it is easier to drink (the difference in the content of carbon dioxide - "bubbles") and to real ales - have to go to England, which I also love.

The main difference from the ale lager - fermentation process. El is quick top fermentation at high temperature (typically 15 to 24 ° C). After fermentation, the yeast remains at the surface, from where the name "mount". Due to the high temperature to produce more microbes and fungi than the bottom-fermenting (lager do so), so such beers are perishable.

When fermented, a special yeast that are raised in the process of fermentation with carbon dioxide bubbles to the surface of the wort. Traditional ale made only from barley malt, hops, water and yeast. However, in some grades of British and Irish ale now added sugar, and barley, rice or corn starch.

British ale is fermented for three to five days. After that, the young al cooled, it dobrazhivaetsya and clarified, and then it is poured into barrels.

In the UK, El not filtered or pasteurized. It is usually called real ale - "real ale" (in Russian like a drink in our days is called "live" beer, to emphasize its difference from pasteurized beer).

58 photos

The largest and central FULLER'S Brewery is located in London, 25 minutes' drive from the city center. It is still a family business.

3.

4. Before the start of the tour all meet in the pub, which, judging by the photos, it has not changed much since 1920. In general, he is about 170-190 years (just the staff and could not speak).

5.

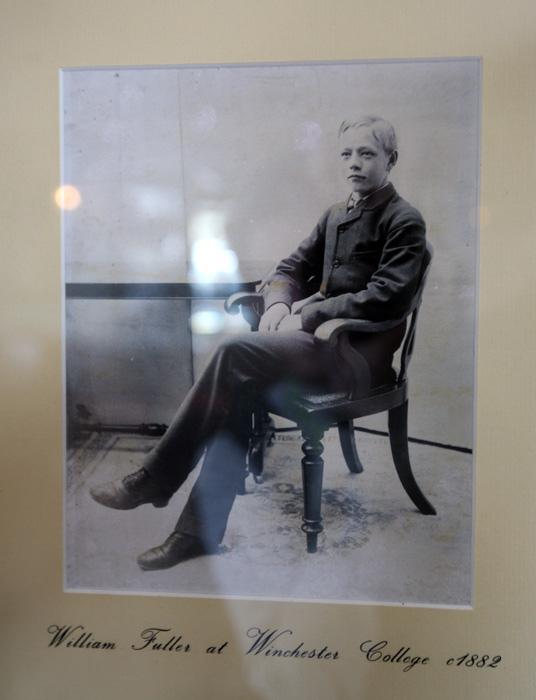

6. Inside everything uvesheny old photographs.

7.

8.

9.

10. While all are collected, you can enjoy a most tasty ale!

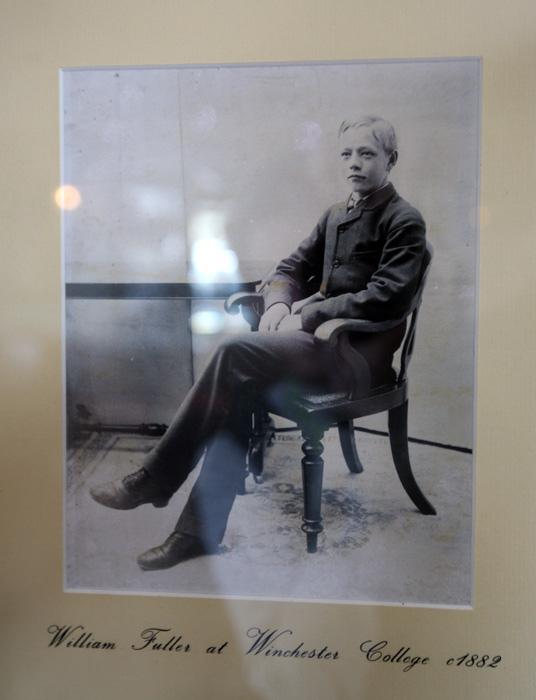

11. Considering the pictures, you know, that people are able to work!

12

13. JOHN BIRD FULLER, 1801-1872. One of the three partners FULLER'S, SMITH & TURNER. 1845.

14

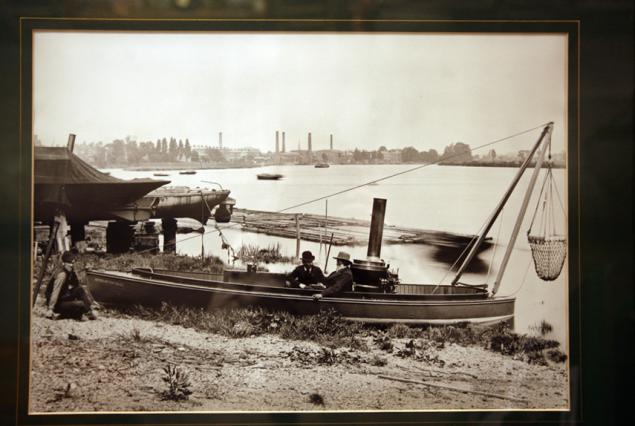

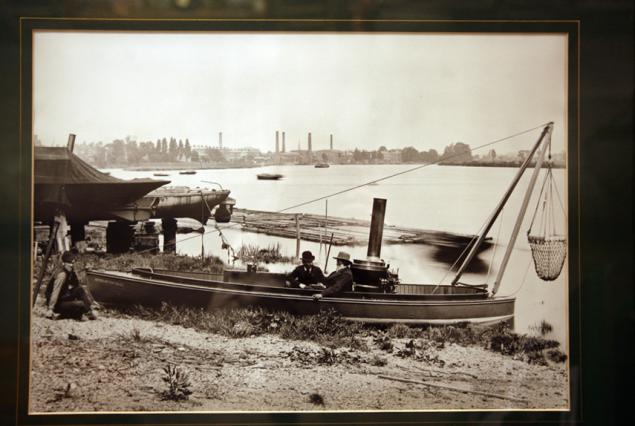

15. The tour begins with the fact that we pass along the entire brewery and go to the Thames. Here, our guide told me that the Thames was of great importance for the brewery, because this is an ideal scheme of transporting beer in London.

16.

17. With great pride, said that they have growing wisteria, which has no equal in the whole district. Is that another one in Kew Gardens.

18. dumped waste production and a favorite treat cows.

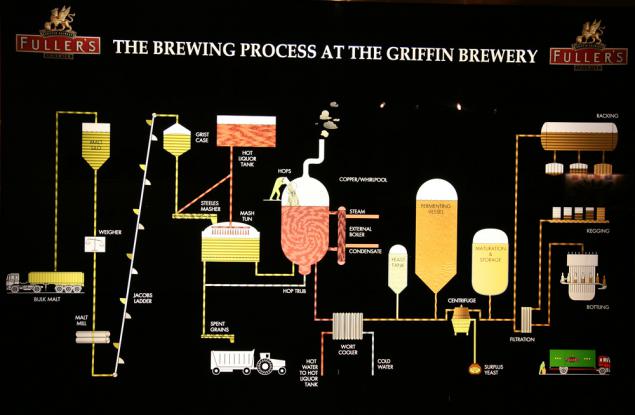

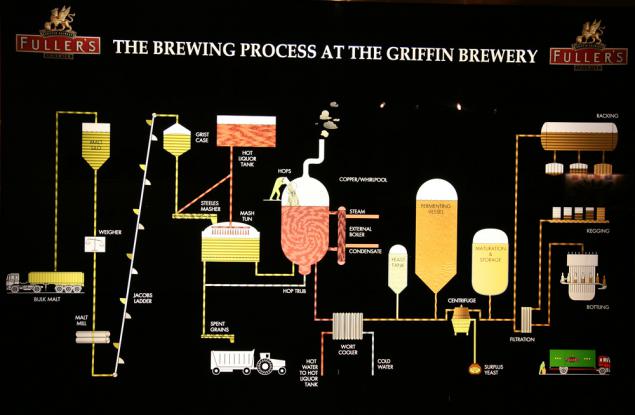

19. All were given orange vests and we went to production. First, on a beautiful stand seeing what's inside the whole process elevareniya.

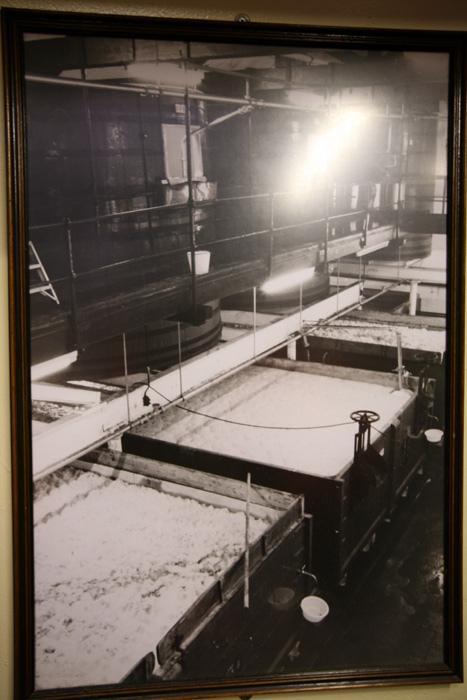

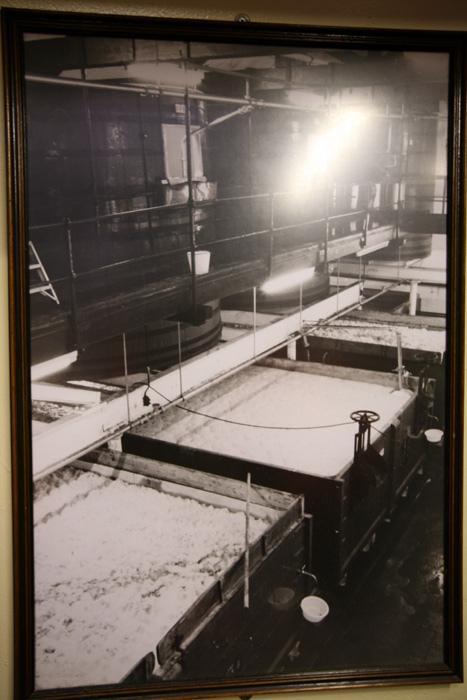

20. Start with the historical part. Before al prepared here in these containers.

21.

22.

23. To clean the boiler down to two workers manually washed everything.

24.

25

26. We rise up and down the tube with a characteristic knock flying malt.

27. But in fact he did. All you can try "to the tooth", smell and touch.

28. Depending on the heat treatment received different malt - is less than or darker. This will determine the color and taste of the beer.

29. The malt used - of English origin. But hop - Czech, but so do the American yeast.

30.

31. Today, El brewed here in these modern systems. The process is automated, always hang the plasma, which provides information about the process of preparation of ale, followed by the operator.

32.

32.

34. At the brewery has its own laboratory, where tests are constantly checking and drink. Besides, FULLER'S constantly coming up with new beers, experiment and do not stand still.

35. After the primary fermentation, the beer is quenched, and it dobrazhivaetsya and clarified in special tanks.

36. Throughout the white tube - this is the cooling system.

37.

38. In the good old days, even though the workers and was put on a pair of pints a day, they did not hesitate to scoop straight from these reservoirs.

39

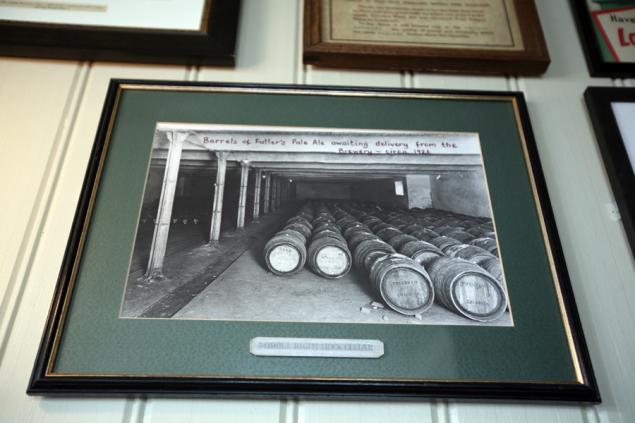

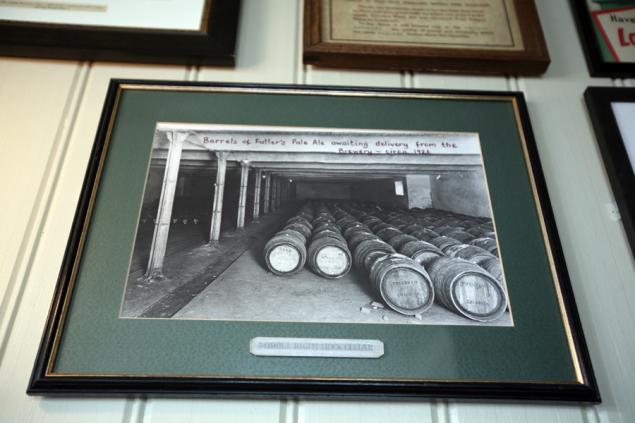

40. Previously, El poured into wooden barrels. Did not throw, preserved for history.

41

42. Now all the iron, and the process is automated once again. Virtually non-stop driving up the empty barrels, they are washed, they poured fresh beer and goes straight to the pubs.

43. This German "hand", interchanging barrels, the brewery has cost 1 000 000 EUR.

44. And on the street a haven for beer lovers.

45. Directly Gulf of beer in barrels. Officer evaluates the quality ale brewery.

46. This is the biggest brewery FULLER'S in England. Her performance - one million pints a week. In total there are about 100 (if I remember correctly). The transfer of production to other countries they are not intentional. Want to try real ale - come on England!

47. Pleasant ear noisy process of loading and unloading of beer barrels.

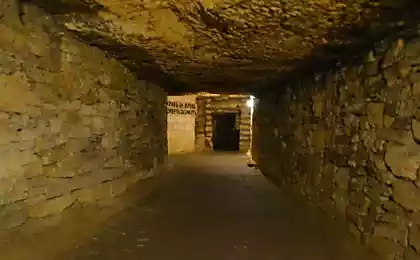

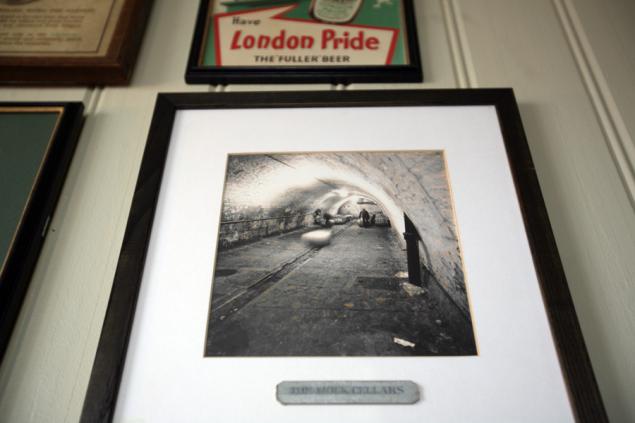

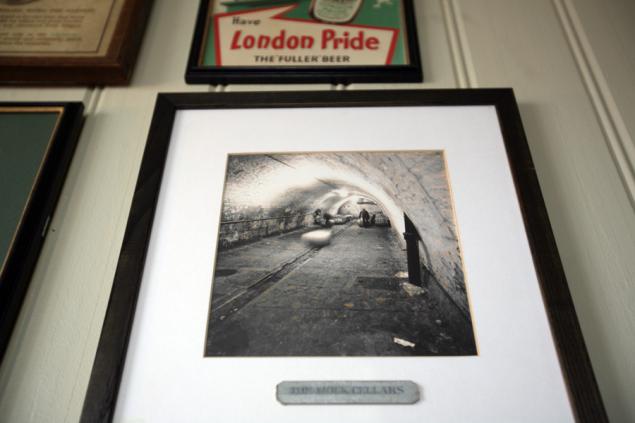

48. That's the whole tour of the production. And then the fun begins - tasting! There is everything in the cellar, where carefully collected everything that has to do with the history of FULLER'S.

49.

50

51

52

53. Try everything you can and in any quantity.

54. You can talk a little beer and then enjoy a delicious aroma.

55. Oh, how emotionally sat and drank ale brewed only!

56. I did not come empty-handed. More houses looked the statistics and saw that 40% of Russians drink Zhigulevskoye 25 - Baltic. I decided to take a second and gave it to our tour guide, who, by the way, almost all his life working at the brewery and had become a partner. Asking how many degrees in seven, he immediately gave back a bottle collector's ale which we have not yet discovered.

57. Well, you can finish the tour trekking drunk in company store.

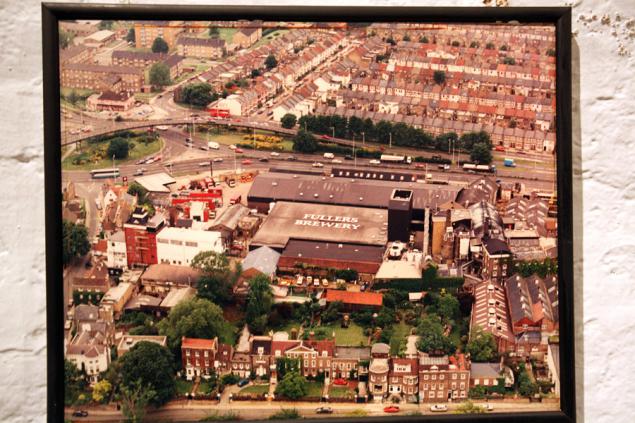

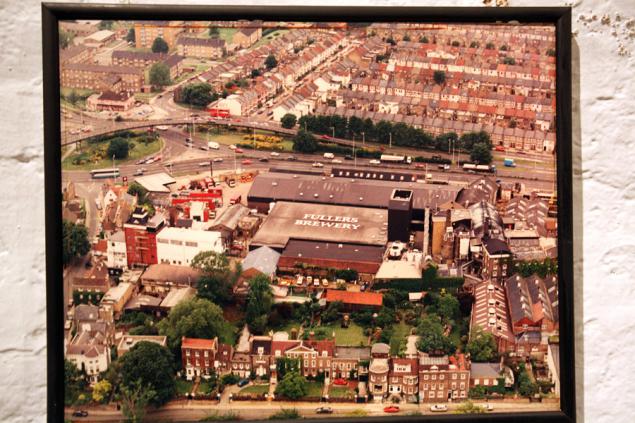

58. And this is the brewery looked a few decades ago. Note the narrow houses behind it - a typical British homes.

Source:

I love ale. It is much more aromatic lager (usually light beer, to which we are accustomed to), it is easier to drink (the difference in the content of carbon dioxide - "bubbles") and to real ales - have to go to England, which I also love.

The main difference from the ale lager - fermentation process. El is quick top fermentation at high temperature (typically 15 to 24 ° C). After fermentation, the yeast remains at the surface, from where the name "mount". Due to the high temperature to produce more microbes and fungi than the bottom-fermenting (lager do so), so such beers are perishable.

When fermented, a special yeast that are raised in the process of fermentation with carbon dioxide bubbles to the surface of the wort. Traditional ale made only from barley malt, hops, water and yeast. However, in some grades of British and Irish ale now added sugar, and barley, rice or corn starch.

British ale is fermented for three to five days. After that, the young al cooled, it dobrazhivaetsya and clarified, and then it is poured into barrels.

In the UK, El not filtered or pasteurized. It is usually called real ale - "real ale" (in Russian like a drink in our days is called "live" beer, to emphasize its difference from pasteurized beer).

58 photos

The largest and central FULLER'S Brewery is located in London, 25 minutes' drive from the city center. It is still a family business.

3.

4. Before the start of the tour all meet in the pub, which, judging by the photos, it has not changed much since 1920. In general, he is about 170-190 years (just the staff and could not speak).

5.

6. Inside everything uvesheny old photographs.

7.

8.

9.

10. While all are collected, you can enjoy a most tasty ale!

11. Considering the pictures, you know, that people are able to work!

12

13. JOHN BIRD FULLER, 1801-1872. One of the three partners FULLER'S, SMITH & TURNER. 1845.

14

15. The tour begins with the fact that we pass along the entire brewery and go to the Thames. Here, our guide told me that the Thames was of great importance for the brewery, because this is an ideal scheme of transporting beer in London.

16.

17. With great pride, said that they have growing wisteria, which has no equal in the whole district. Is that another one in Kew Gardens.

18. dumped waste production and a favorite treat cows.

19. All were given orange vests and we went to production. First, on a beautiful stand seeing what's inside the whole process elevareniya.

20. Start with the historical part. Before al prepared here in these containers.

21.

22.

23. To clean the boiler down to two workers manually washed everything.

24.

25

26. We rise up and down the tube with a characteristic knock flying malt.

27. But in fact he did. All you can try "to the tooth", smell and touch.

28. Depending on the heat treatment received different malt - is less than or darker. This will determine the color and taste of the beer.

29. The malt used - of English origin. But hop - Czech, but so do the American yeast.

30.

31. Today, El brewed here in these modern systems. The process is automated, always hang the plasma, which provides information about the process of preparation of ale, followed by the operator.

32.

32.

34. At the brewery has its own laboratory, where tests are constantly checking and drink. Besides, FULLER'S constantly coming up with new beers, experiment and do not stand still.

35. After the primary fermentation, the beer is quenched, and it dobrazhivaetsya and clarified in special tanks.

36. Throughout the white tube - this is the cooling system.

37.

38. In the good old days, even though the workers and was put on a pair of pints a day, they did not hesitate to scoop straight from these reservoirs.

39

40. Previously, El poured into wooden barrels. Did not throw, preserved for history.

41

42. Now all the iron, and the process is automated once again. Virtually non-stop driving up the empty barrels, they are washed, they poured fresh beer and goes straight to the pubs.

43. This German "hand", interchanging barrels, the brewery has cost 1 000 000 EUR.

44. And on the street a haven for beer lovers.

45. Directly Gulf of beer in barrels. Officer evaluates the quality ale brewery.

46. This is the biggest brewery FULLER'S in England. Her performance - one million pints a week. In total there are about 100 (if I remember correctly). The transfer of production to other countries they are not intentional. Want to try real ale - come on England!

47. Pleasant ear noisy process of loading and unloading of beer barrels.

48. That's the whole tour of the production. And then the fun begins - tasting! There is everything in the cellar, where carefully collected everything that has to do with the history of FULLER'S.

49.

50

51

52

53. Try everything you can and in any quantity.

54. You can talk a little beer and then enjoy a delicious aroma.

55. Oh, how emotionally sat and drank ale brewed only!

56. I did not come empty-handed. More houses looked the statistics and saw that 40% of Russians drink Zhigulevskoye 25 - Baltic. I decided to take a second and gave it to our tour guide, who, by the way, almost all his life working at the brewery and had become a partner. Asking how many degrees in seven, he immediately gave back a bottle collector's ale which we have not yet discovered.

57. Well, you can finish the tour trekking drunk in company store.

58. And this is the brewery looked a few decades ago. Note the narrow houses behind it - a typical British homes.

Source: