844

Vintage beautiful legend

The author writes, zizis:

There is a beautiful old legend which talks about the king who was interested in daughters how much they love his father. One said that she loved him as the sky, the second gold and third as salt. The king did not understand the last daughter got angry and kicked out of the house, and all the salt in the kingdom turned into gold. That's when the king realized how much he loved his daughter.

On a visit to the kings of today we do not go, but we'll see how salt is mined open pit and I will explain how this has happened before.

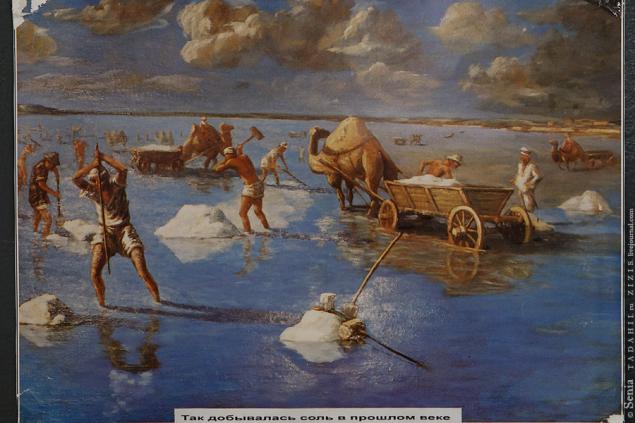

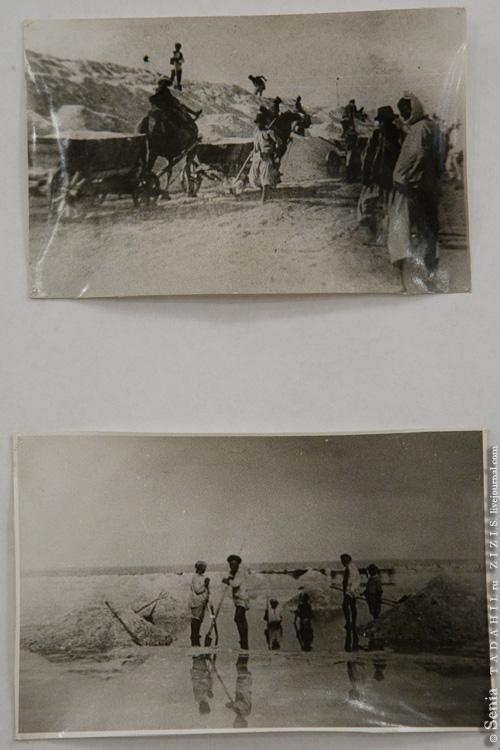

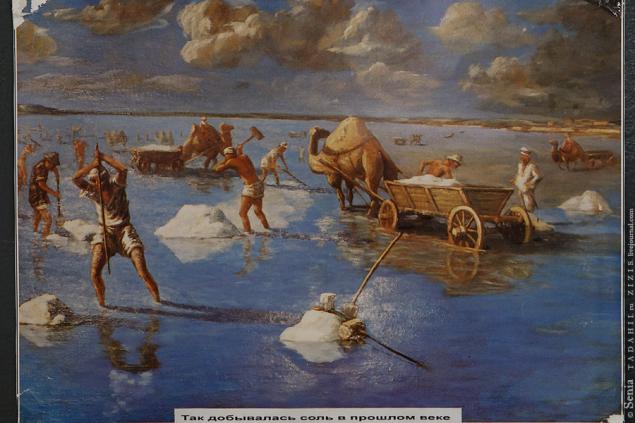

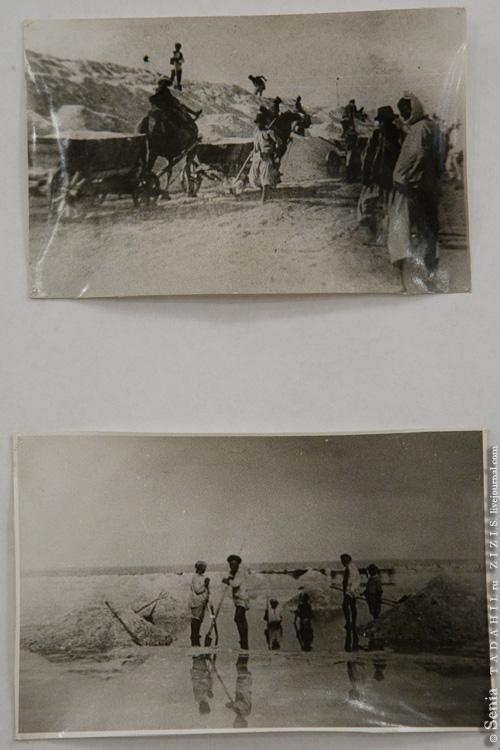

Extraction of salt lakes in the Lower Volga region began in the Middle Ages, and perhaps earlier.

The main site of production was Elton and Baskunchak. On salt production worked mainly Tatars, Ivan the Terrible was kicked off their land, Kyrgyz and Russian peasants.

Workers lomschiki worked 12-14 hours in brine, which in summer is heated to 45-50 degrees. A man in such conditions endured ten or fifteen years, after which either die or become disabled.

In 1810, pay the workers for 1000 pounds (16 tons) of salt was 3, 52 rubles. True, after the development of salt production on a lake and construction of the railway board rose to 8, 33 rubles. Sell the salt in the same 1810 to 25 cents per pud, if you subtract the cost of transportation, you can calculate the approximate income of the owners of salt mining. By the end of the XIX century on the extraction of salt it employed 5,000 people and as many camels.

The young Soviet state has brought not only the liberation of women of the East, but also in the salt mining mechanization. Naturally, once it produced downsizing.

In the early 20-ies of the last century, the engineer Yuri Makarov was invented "Solesos" principle of which is the name still used today, I will talk about this machine below. And even with pictures.

Naturally, after the commissioning of the harvester productivity increased significantly. But the need for salt is also increased. If before the bulk of the salt came for food, the food is now only 20% of the salt produced, the rest of the so-called Industrial salt for chemical reprocessing and the needs of industry.

And with the increased production and the question arose about the size of the natural reserve of salt in the lake. In 1927, the lake laid reconnaissance borehole to determine the capacity of the salt formation. Drilling stopped at a depth of 257 m, and before reaching the bedrock. Again, it is necessary to clarify that the call Baskunchak lake, probably not entirely correct. At its core is hollow, which "flows" under the weight of the salt of the earth from the nearby salt domes. By and large, lake Baskunchak and mountain Bogdo is the same geological object, salt domes and salt basin. With careful, prudent development of this unique deposit reserves of salt are practically inexhaustible, the restoration generated 6-meter layer takes several years.

Recently formed a complex situation with the ecological state of the lake. Not only will dramatically increase the number of tourists bring with them the garbage and the neighbor-giant "Knauf Gypsum Baskunchak» Periodically drain the water into the nearby drainage basin. From there the water containing including strontium and cadmium gets into the lake. Between "Bassolé" and Knauf'om misunderstandings occur regularly, and on an old Russian tradition, without the intervention of the king to decide the matter could not. The role of the king took over Alexander Zhilkin, Governor of Astrakhan region, and at the moment the parties have come to an understanding.

As I said, since the invention of solesosa how it works has not changed, although it is the fourth generation of these machines. All movements take place on the rails. As the development of pathways, clearly visible traces of the sleepers. Combine makes the production where he stood a couple of days ago. Now the depth of development is 6 meters.

Well, let's see how this unit works. Those who are familiar with the principle of the dredger is nothing no need to explain, the principle is the same. By the way, once again I remind feet from extreme vertical development of the rail 6 meters.

Two cutter-disintegrant at approximately 36 rev / min. crushed salt crusts into small pieces in the 5-35 mm.

After the passage of the combine is that's a little more than the width of the track meters. Replaceable cutters and several years production width was two meters.

Further, the movable tube sucks the salt slurry (solepulpu), consisting of pieces of brine and salt. To pieces salts maintained in suspension needs a relatively large speed. Rapa is absorbed at a rate of not less than 2 m / sec (7 km / h).

After passing through the rotor, additional grinding and several washes with brine mixture gets to rumble, where salt is separated from the brine.

Rapa merges back into the lake ...

... And salt to rumble and conveyor falls into the cars, and that is sent to Akhtubinsk and then up the Volga.

Thus, solesos is just a big pump with a chopper and a roar mounted on railway or floating platform. Performance solesosa about 300 tons per hour.

From cars excess moisture is removed through a natural gap, it looks impressive, almost like a cave.

The amount of salt production in 2007 amounted to 1, 42 million. Tons, 250 thousand tons of food that.

Well, let's see the conditions in which works of contemporary soledobytchiki? Solekombayn as almost any large modern car running on electricity. The control panel consists of buttons, toggle switches and analog devices. However, adding a small computer monitor. With this control panel is the main control (speed is a cutter suction power, the speed screen). The cabin is about 5 square meters, equipped with air conditioning. Without it, it would be difficult to work under the sun in the heat over 60 degrees Celsius.

Combine served by a team of two people, a change of 8 hours. Working around the clock, processor stops only in case of breakage. If a serious failure, a few kilometers away, in the shop, is a spare processor.

Remote from which the salt loading into wagons. Position one of the combiner paid on production. The production season (April-October) salary is about 28 m. Rubles, in the winter, these same people make the repair and maintenance of equipment, preparation for the next season, and get about 15 m. Rubles. Thus, the average salary is 21, 5 thousand. Needless to say that the summer vacation no one goes?

Such processors are available today Minsk Tractor Plant, the birthplace of this unit a mystery to me.

The heart of the combine - diesel. Two diesel engines generate electricity for many motors. Specifically, it produces generators. I love the smell of diesel in the hot oil and a bit of exhaust. Hmm ... But in reasonable doses

Unfortunately, nothing can be said about the characteristics of the engine, there is no such information. Just a very large and noisy

Briefly summing up we can say that the working conditions soledobytchikov two centuries improved payment increased. Do you have all the numbers to count themselves. I turned at the approximate estimates that in 1810 brought one ton of 0, 22 rubles working salt production. In 2010, the same brings a ton of 1, 64 rubles. The progress is obvious.

via zizis

And the video from blogger macos:

3:01

Source:

There is a beautiful old legend which talks about the king who was interested in daughters how much they love his father. One said that she loved him as the sky, the second gold and third as salt. The king did not understand the last daughter got angry and kicked out of the house, and all the salt in the kingdom turned into gold. That's when the king realized how much he loved his daughter.

On a visit to the kings of today we do not go, but we'll see how salt is mined open pit and I will explain how this has happened before.

Extraction of salt lakes in the Lower Volga region began in the Middle Ages, and perhaps earlier.

The main site of production was Elton and Baskunchak. On salt production worked mainly Tatars, Ivan the Terrible was kicked off their land, Kyrgyz and Russian peasants.

Workers lomschiki worked 12-14 hours in brine, which in summer is heated to 45-50 degrees. A man in such conditions endured ten or fifteen years, after which either die or become disabled.

In 1810, pay the workers for 1000 pounds (16 tons) of salt was 3, 52 rubles. True, after the development of salt production on a lake and construction of the railway board rose to 8, 33 rubles. Sell the salt in the same 1810 to 25 cents per pud, if you subtract the cost of transportation, you can calculate the approximate income of the owners of salt mining. By the end of the XIX century on the extraction of salt it employed 5,000 people and as many camels.

The young Soviet state has brought not only the liberation of women of the East, but also in the salt mining mechanization. Naturally, once it produced downsizing.

In the early 20-ies of the last century, the engineer Yuri Makarov was invented "Solesos" principle of which is the name still used today, I will talk about this machine below. And even with pictures.

Naturally, after the commissioning of the harvester productivity increased significantly. But the need for salt is also increased. If before the bulk of the salt came for food, the food is now only 20% of the salt produced, the rest of the so-called Industrial salt for chemical reprocessing and the needs of industry.

And with the increased production and the question arose about the size of the natural reserve of salt in the lake. In 1927, the lake laid reconnaissance borehole to determine the capacity of the salt formation. Drilling stopped at a depth of 257 m, and before reaching the bedrock. Again, it is necessary to clarify that the call Baskunchak lake, probably not entirely correct. At its core is hollow, which "flows" under the weight of the salt of the earth from the nearby salt domes. By and large, lake Baskunchak and mountain Bogdo is the same geological object, salt domes and salt basin. With careful, prudent development of this unique deposit reserves of salt are practically inexhaustible, the restoration generated 6-meter layer takes several years.

Recently formed a complex situation with the ecological state of the lake. Not only will dramatically increase the number of tourists bring with them the garbage and the neighbor-giant "Knauf Gypsum Baskunchak» Periodically drain the water into the nearby drainage basin. From there the water containing including strontium and cadmium gets into the lake. Between "Bassolé" and Knauf'om misunderstandings occur regularly, and on an old Russian tradition, without the intervention of the king to decide the matter could not. The role of the king took over Alexander Zhilkin, Governor of Astrakhan region, and at the moment the parties have come to an understanding.

As I said, since the invention of solesosa how it works has not changed, although it is the fourth generation of these machines. All movements take place on the rails. As the development of pathways, clearly visible traces of the sleepers. Combine makes the production where he stood a couple of days ago. Now the depth of development is 6 meters.

Well, let's see how this unit works. Those who are familiar with the principle of the dredger is nothing no need to explain, the principle is the same. By the way, once again I remind feet from extreme vertical development of the rail 6 meters.

Two cutter-disintegrant at approximately 36 rev / min. crushed salt crusts into small pieces in the 5-35 mm.

After the passage of the combine is that's a little more than the width of the track meters. Replaceable cutters and several years production width was two meters.

Further, the movable tube sucks the salt slurry (solepulpu), consisting of pieces of brine and salt. To pieces salts maintained in suspension needs a relatively large speed. Rapa is absorbed at a rate of not less than 2 m / sec (7 km / h).

After passing through the rotor, additional grinding and several washes with brine mixture gets to rumble, where salt is separated from the brine.

Rapa merges back into the lake ...

... And salt to rumble and conveyor falls into the cars, and that is sent to Akhtubinsk and then up the Volga.

Thus, solesos is just a big pump with a chopper and a roar mounted on railway or floating platform. Performance solesosa about 300 tons per hour.

From cars excess moisture is removed through a natural gap, it looks impressive, almost like a cave.

The amount of salt production in 2007 amounted to 1, 42 million. Tons, 250 thousand tons of food that.

Well, let's see the conditions in which works of contemporary soledobytchiki? Solekombayn as almost any large modern car running on electricity. The control panel consists of buttons, toggle switches and analog devices. However, adding a small computer monitor. With this control panel is the main control (speed is a cutter suction power, the speed screen). The cabin is about 5 square meters, equipped with air conditioning. Without it, it would be difficult to work under the sun in the heat over 60 degrees Celsius.

Combine served by a team of two people, a change of 8 hours. Working around the clock, processor stops only in case of breakage. If a serious failure, a few kilometers away, in the shop, is a spare processor.

Remote from which the salt loading into wagons. Position one of the combiner paid on production. The production season (April-October) salary is about 28 m. Rubles, in the winter, these same people make the repair and maintenance of equipment, preparation for the next season, and get about 15 m. Rubles. Thus, the average salary is 21, 5 thousand. Needless to say that the summer vacation no one goes?

Such processors are available today Minsk Tractor Plant, the birthplace of this unit a mystery to me.

The heart of the combine - diesel. Two diesel engines generate electricity for many motors. Specifically, it produces generators. I love the smell of diesel in the hot oil and a bit of exhaust. Hmm ... But in reasonable doses

Unfortunately, nothing can be said about the characteristics of the engine, there is no such information. Just a very large and noisy

Briefly summing up we can say that the working conditions soledobytchikov two centuries improved payment increased. Do you have all the numbers to count themselves. I turned at the approximate estimates that in 1810 brought one ton of 0, 22 rubles working salt production. In 2010, the same brings a ton of 1, 64 rubles. The progress is obvious.

via zizis

And the video from blogger macos:

3:01

Source: