628

How do komplektuhu KIA

The plant is located on the premises Kia in Zilina (Slovakia), but is a separate proceeding, which makes components and some components: bumpers, dashboard, front and rear suspension, engines. Then it all goes to the main conveyor to the final assembly of the KIA. This we shall see later, and is studying the production of plastic components.

Unfortunately, the text materials on the technological process did not let me, so I had to understand himself. In general, everything is simple: the mold poured melted plastic - were finished part. Then she leaves the assembly and warehouse. In the process it is checked if it is necessary to grind, etc.

But the biggest revelation for me was the production of torpedoes. But more on that below.

23 photos via russos

1. Finished products.

2. In such tanks carrying raw material for plastic products.

3. Shop punching.

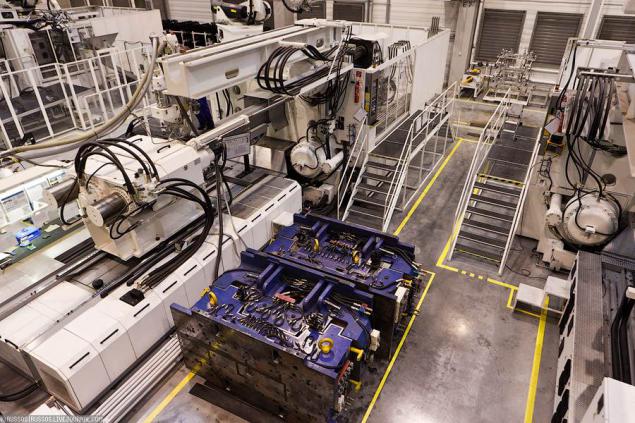

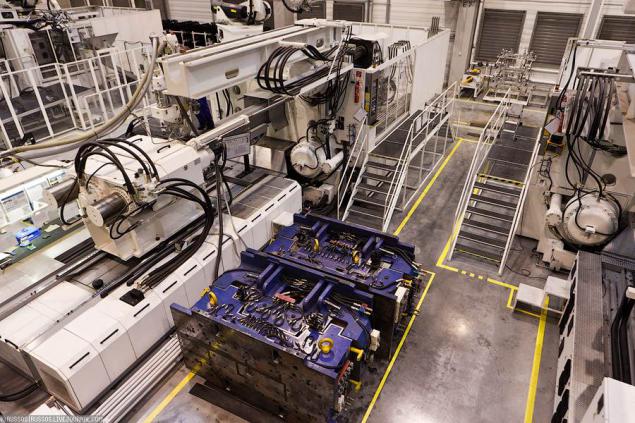

4. The blue mold is fed under pressure from molten plastic, which takes the desired shape.

5. On the line at the same time made the bumper and dash on some models.

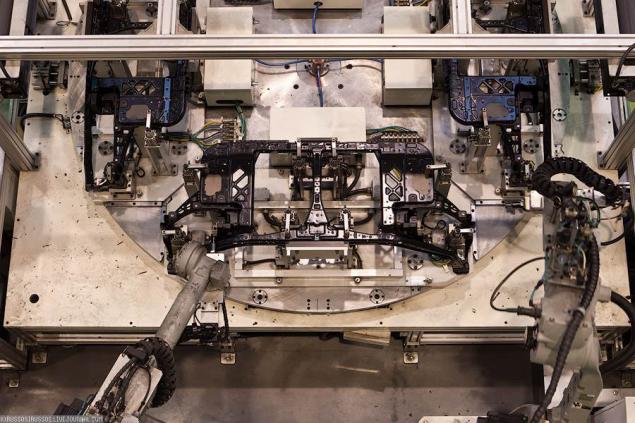

6. At the press stamped dashboard.

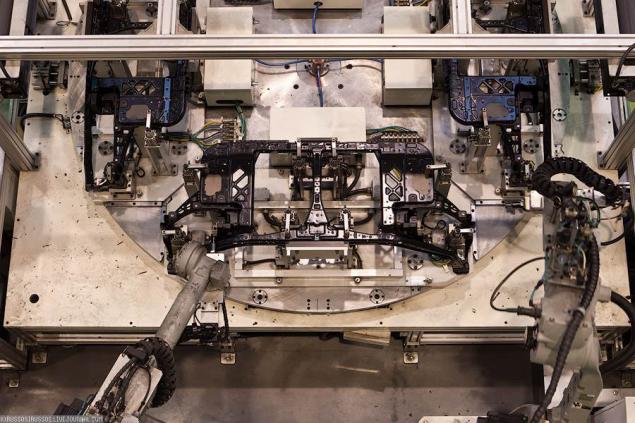

7. Certain items then (this, as I understand it is near the front of the radiator) fall on the machine where the robots carry out further processing.

8. Some components manually cleaned and checked.

9. Paint the dashboard.

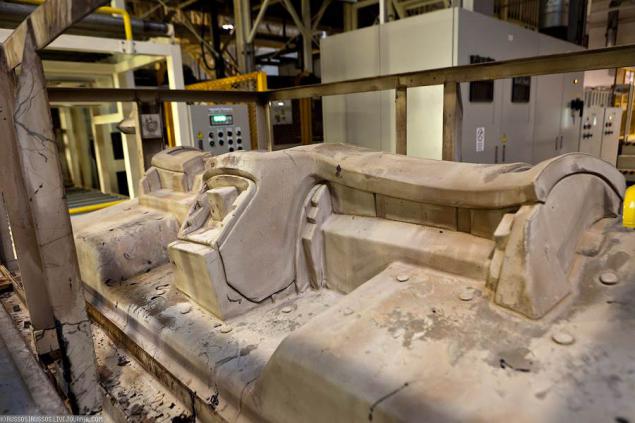

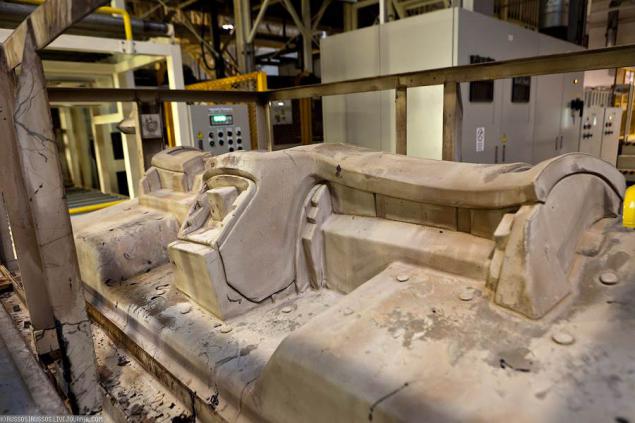

10. Rigid base to the dashboard.

11. And this is something that I was very surprised. Torpedo consists of two layers - the rigid substrate and a soft skin which is then tensioned at the top and under heat sits down. In this mold making skins.

12. The skin is soft and flexible.

13. For me it was a big surprise that the dashboard is composed of two layers.

14. Here it is valid, as the world's interest.

15. But this mold has remained a mystery to me. I assume that there is a connection and two layers. Special workers still something there glued liners and films. Apparently the protection of some parts.

16. Master-model?

17. Storage of ingredients.

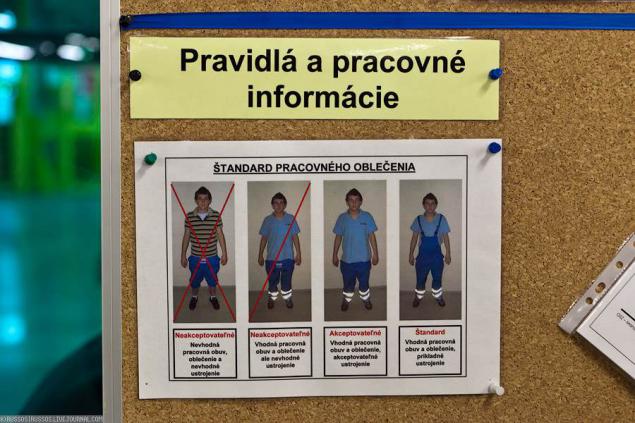

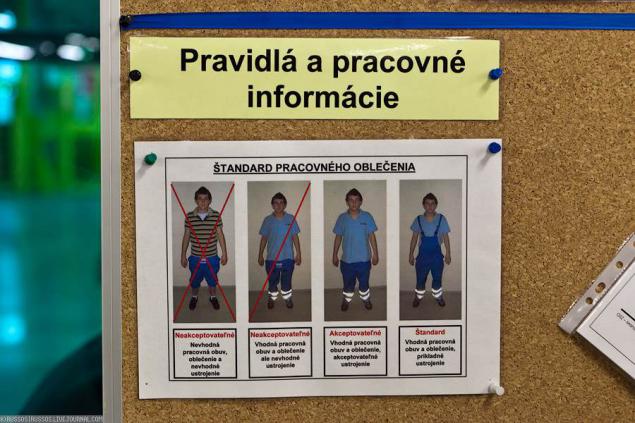

18. Instructions uniforms.

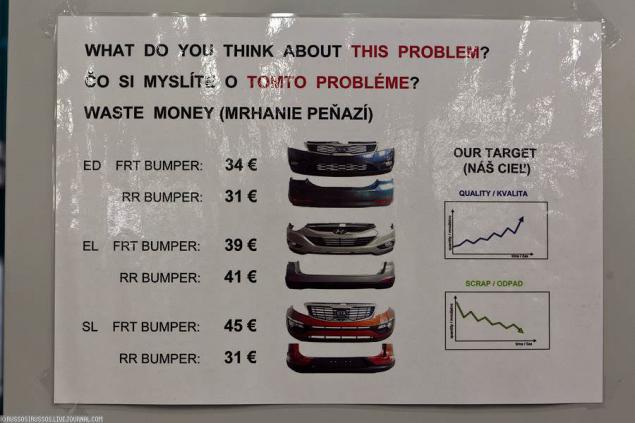

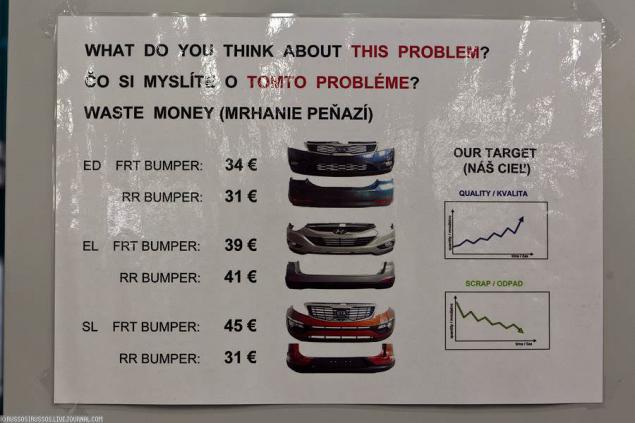

19. SCRAP - it trim. I understand this is a struggle for reducing the amount of scrap with each product. Yes, compare the price of the bumper here in Moscow, and its cost (?) For the plant.

20. Each painted bumpers multiple passes visual inspection and minor scratches immediately sanded.

21. Preparations bumpers.

22. And its assembly on the conveyor.

23. Finished products before sending it to the conveyor.

Source:

Unfortunately, the text materials on the technological process did not let me, so I had to understand himself. In general, everything is simple: the mold poured melted plastic - were finished part. Then she leaves the assembly and warehouse. In the process it is checked if it is necessary to grind, etc.

But the biggest revelation for me was the production of torpedoes. But more on that below.

23 photos via russos

1. Finished products.

2. In such tanks carrying raw material for plastic products.

3. Shop punching.

4. The blue mold is fed under pressure from molten plastic, which takes the desired shape.

5. On the line at the same time made the bumper and dash on some models.

6. At the press stamped dashboard.

7. Certain items then (this, as I understand it is near the front of the radiator) fall on the machine where the robots carry out further processing.

8. Some components manually cleaned and checked.

9. Paint the dashboard.

10. Rigid base to the dashboard.

11. And this is something that I was very surprised. Torpedo consists of two layers - the rigid substrate and a soft skin which is then tensioned at the top and under heat sits down. In this mold making skins.

12. The skin is soft and flexible.

13. For me it was a big surprise that the dashboard is composed of two layers.

14. Here it is valid, as the world's interest.

15. But this mold has remained a mystery to me. I assume that there is a connection and two layers. Special workers still something there glued liners and films. Apparently the protection of some parts.

16. Master-model?

17. Storage of ingredients.

18. Instructions uniforms.

19. SCRAP - it trim. I understand this is a struggle for reducing the amount of scrap with each product. Yes, compare the price of the bumper here in Moscow, and its cost (?) For the plant.

20. Each painted bumpers multiple passes visual inspection and minor scratches immediately sanded.

21. Preparations bumpers.

22. And its assembly on the conveyor.

23. Finished products before sending it to the conveyor.

Source: