637

Work at the smithy.

Dear Yapovtsy. I think you will be interesting to see what, she blacksmith work in reality. After all, the film shows the thick, unshaven, drunk or nichrome blacksmiths who do not, either directly handyman per hour and able to process a ton of steel swords.

Duck gentlemen, here's my little photo report, and how it is produced.

It will be a little ph, please do not break. I will inform you how to finish.

1. It starts with 12 square steel. It is cut into pieces of 8 cm. And welded together to form a square.

The photo has peeled shiny squares, and peeled

The tool now bullying:

03. Then the twisted tube is cut into 80 cm. Pieces.

04. Those eggs - view profile.

Photography has a later stage.

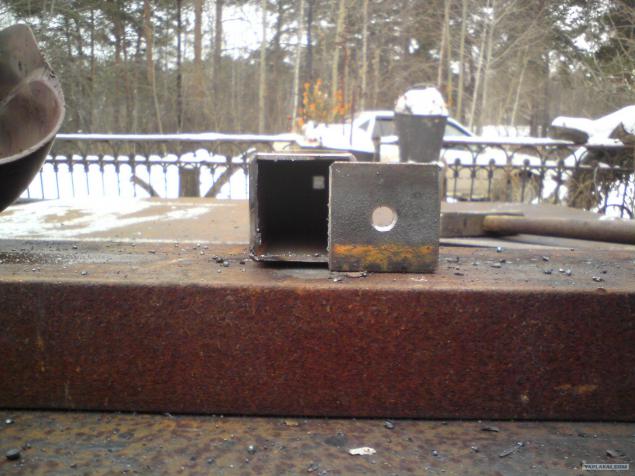

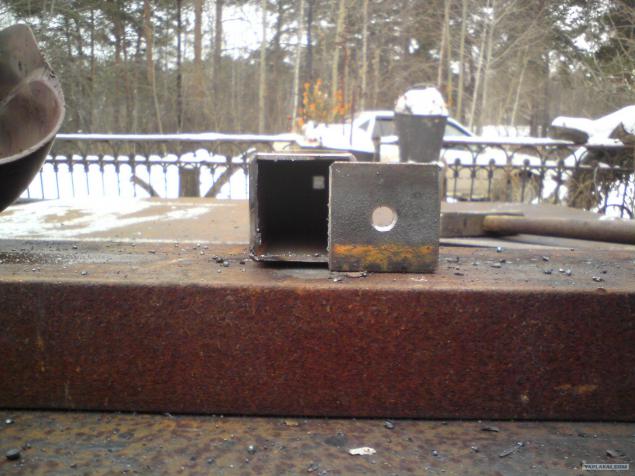

05. Then, as the same is taken 40 square and cut into pieces of 40 and 60 centimeters. To which from all over the welded boxes: -

06. View profile after grinding mild abrasive.

07. Get ready constructor:

08. Begin the assembly:

With clamps to fasten the formwork Designer and go to welding.

09. More.

10. The finished product.

11. Some moments I did not have time to shoot, as the work ... work and work. As a result, after grinding weld get just such a beauty:

12. This is followed by lunch ... cook dumplings on the hearth in cast iron boilers ... try? The temperature of the hearth ~ 800 degrees.

13. After lunch, we go to work on. Currently, the pillars are almost ready. It remains only to make the top of the cap and balls to them.

Actually covers a strip of steel 40x40 with a hole in the center. Drilling on tokarke.

14. That's what we get:

15. After polishing, move out. Welded caps in place:

16. Welding was successful. First, we catch and then boil.

17. After provarkoy grind. And prepared beautifully.

18. Next dark carries us on the straight finish ... We put the boxes, the ones who did in the beginning.

19. We understand that they are not suitable Nichrome and go jerk off ... in the truest sense of the word.

20 are welded, grind. It turns out that's how krasyavo and well: -

21. A look at the snow around ... and understand what is happening in the lungs.

22. Snow is just black. For example, he kicked his shoes. Compare say so ...

23. 12 "ready" pillars. So far, no balls at the top.

Each pillar weighs about 17 kg ... I have them in 3 pieces dragged at once.

24. Dale go balls ... Starts a steel pipe diameter of 40 mm.

25. With hellish hrenoviny called vulcanite ...

26. It is cut into smaller blanks of 40 mm. in length. To scale sfotkal pad with chewing gum ... nebylo anything at hand.

27. Cutting a thick pipe is time consuming, and thus a lot of heat ...

Do not resist, did all the same ...

Heated with blanks in the snow.

28. With the help forge blanks are heated to 800 degrees.

Fotik did not pull ... Sori for quality video.

29. Obtained Hells barrels death ... fall down on this leg, and all without a leg. Burns in seconds.

30. Then they are crushed under the pressure of the balls to the state.

31. Unfortunately, the further process was filmed in mind the presence of Sheba, and Abraham-anal mode.

Next, I will say that then, the beads are processed, they drilled holes. Threaded. And they are using the studs are mounted on poles. And then they are painted in matt black.

For a place that, photos of our previous work. Wicker fence. Fully cast iron and steel.

P / s / that's it! ..

And here's another fotochki - our shop.

Source:

Duck gentlemen, here's my little photo report, and how it is produced.

It will be a little ph, please do not break. I will inform you how to finish.

1. It starts with 12 square steel. It is cut into pieces of 8 cm. And welded together to form a square.

The photo has peeled shiny squares, and peeled

The tool now bullying:

03. Then the twisted tube is cut into 80 cm. Pieces.

04. Those eggs - view profile.

Photography has a later stage.

05. Then, as the same is taken 40 square and cut into pieces of 40 and 60 centimeters. To which from all over the welded boxes: -

06. View profile after grinding mild abrasive.

07. Get ready constructor:

08. Begin the assembly:

With clamps to fasten the formwork Designer and go to welding.

09. More.

10. The finished product.

11. Some moments I did not have time to shoot, as the work ... work and work. As a result, after grinding weld get just such a beauty:

12. This is followed by lunch ... cook dumplings on the hearth in cast iron boilers ... try? The temperature of the hearth ~ 800 degrees.

13. After lunch, we go to work on. Currently, the pillars are almost ready. It remains only to make the top of the cap and balls to them.

Actually covers a strip of steel 40x40 with a hole in the center. Drilling on tokarke.

14. That's what we get:

15. After polishing, move out. Welded caps in place:

16. Welding was successful. First, we catch and then boil.

17. After provarkoy grind. And prepared beautifully.

18. Next dark carries us on the straight finish ... We put the boxes, the ones who did in the beginning.

19. We understand that they are not suitable Nichrome and go jerk off ... in the truest sense of the word.

20 are welded, grind. It turns out that's how krasyavo and well: -

21. A look at the snow around ... and understand what is happening in the lungs.

22. Snow is just black. For example, he kicked his shoes. Compare say so ...

23. 12 "ready" pillars. So far, no balls at the top.

Each pillar weighs about 17 kg ... I have them in 3 pieces dragged at once.

24. Dale go balls ... Starts a steel pipe diameter of 40 mm.

25. With hellish hrenoviny called vulcanite ...

26. It is cut into smaller blanks of 40 mm. in length. To scale sfotkal pad with chewing gum ... nebylo anything at hand.

27. Cutting a thick pipe is time consuming, and thus a lot of heat ...

Do not resist, did all the same ...

Heated with blanks in the snow.

28. With the help forge blanks are heated to 800 degrees.

Fotik did not pull ... Sori for quality video.

29. Obtained Hells barrels death ... fall down on this leg, and all without a leg. Burns in seconds.

30. Then they are crushed under the pressure of the balls to the state.

31. Unfortunately, the further process was filmed in mind the presence of Sheba, and Abraham-anal mode.

Next, I will say that then, the beads are processed, they drilled holes. Threaded. And they are using the studs are mounted on poles. And then they are painted in matt black.

For a place that, photos of our previous work. Wicker fence. Fully cast iron and steel.

P / s / that's it! ..

And here's another fotochki - our shop.

Source: