805

Tobacco Case

Last year, I told how to grow tobacco. Then you virtually visited on a tobacco farm in Chilik district, in the same topic reportage revealed further describes the next steps - Sort, pressing and delivery of tobacco at the point of reception.

34 photos via vvoxpopuli

1. At Chilik farm tobacco leaves are dried naturally in the sun for 3-4 days. Drying is completed when the leaves dry up completely. Remove them in the morning when they are in otvolozhennom form, that is, when, after the wet night air leaves are soft and do not break

2. The cords connect to gavanki and hung on poles in the barn or under a roof. During drying tobacco, protect against wind and moisture

3. In this state, it is stored until ready to sorting

4. From the middle of September until the end of December to begin preparation for the delivery of tobacco. For this sort leaves under pressure and formed into bales. Pictured Haliskhan holding a bunch of future tobacco

5. indoors leaves carefully removed from the gavanok and transmit sorters

6. sorting involved both men and women. It is a process in which the work will be every

7. The cultivation of tobacco is mainly occupied by migrant workers from Kyrgyzstan who go home after putting in December

8. Tobacco is sorted into 6 grades. Grade determined by the color and quality of the leaves. One person can sort up to 60 kg of tobacco per day

9. When sorting tobacco leaves stacked in one direction, and after the press on a mechanical press in bales weighing 14 to 18 kg

10. Ready-wrapped bales of coarse linen cloth for easy transport. Tobacco company buys all the raw materials to the last leaf that provides the guaranteed sales. After the tobacco batch is ready, it is sent to the collection point for the company, "Philip Morris Kazakhstan»

11. According to its schedule brings the farmer ready raw material procurement item. During the delivery point for the day tobacco takes 800-1000 bp

12. Previously, the farmers had a lot more, but because of the economic crisis, their number decreased. According to statistics, in 2002 there were 4,700, but in 2011 had a total of 200

13. With one hectare a farmer collects from 1, 7 to 2, 5 tons of the crop

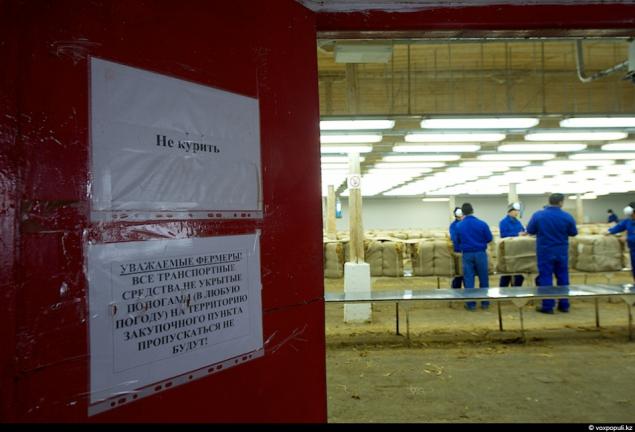

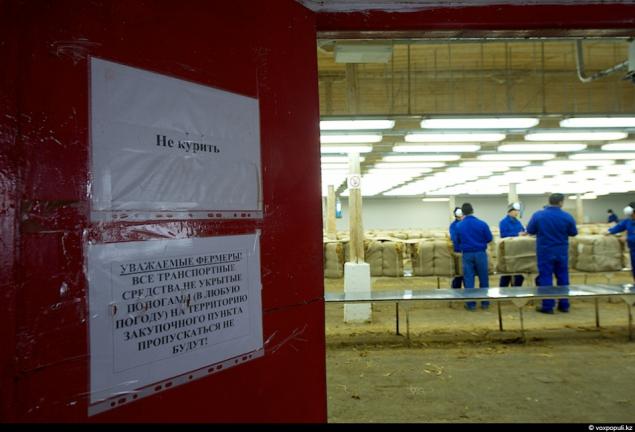

14.

15. Lease raw materials all together: and the farmer and his workers, who cultivated and harvested tobacco, to ensure transparency in future mutual. Recall that after six months of continuous work each employee can earn between 1,000 and 1,500 dollars

16. The bales are loaded on a cart to be delivered to the reception desk

17. Funnily enough, that the marketing of tobacco smoking is prohibited everywhere

18. A farmer in anticipation of the end of the season

19. Bale ready to test

20. The tobacco company is interested in good quality tobacco, so in every possible way to help farmers. For example, provide them with the necessary materials for production, it helps with seeds and advice on farming techniques, irrigation, seedlings, since the first withdrawal leaves

21. In Kazakhstan 6 tobacco companies, which share the market. The largest of them are JTI (44%), "Philip Morris Kazakhstan" (42%) and BAT (8-9%) (according to the newspaper "Course"), but uses only local raw materials, "Philip Morris»

22

23. The expert from the scanner determines the grade of tobacco that affects its value from 98 to 336 tenge per kilogram of tobacco

24. It is important to participate as a farmer and worker, to be seen at what price and what the quality of each bale is received

25. In the process of receiving each bale is opened in 6 places to the expert of the company could identify tobacco. Each bale is pasted barcode, which has all the information about what kind of variety, who the manufacturer, and the time and place of delivery of tobacco

26. Upon delivery, it is desirable to maintain the integrity of the tobacco leaf. In the sort of tobacco affect climatic conditions, proper care and soil parameters. It is estimated that in the south of Kazakhstan's tobacco grows better because of loamy soil, closer to Almaty, the soil is heavier and it affects the quality of

27. Samples of varieties of tobacco "Talgar 28", which is partly used in the production of local brands of cigarettes and exported to Russia, Ukraine, Czech Republic and Lithuania. For foreign brands of cigarettes that are manufactured in Kazakhstan, tobacco use other varieties. He brought specially from Europe

28. Laboratory assistant takes samples to determine moisture

29. The tobacco moisture content is determined for 7 minutes by evaporation and it must not exceed 18%. If the humidity exceeds the permitted limit, the farmers take tobacco back with them, dried and hand pile with the next batch

30. After all the tests stacks re-cross-linked to transport to the warehouse

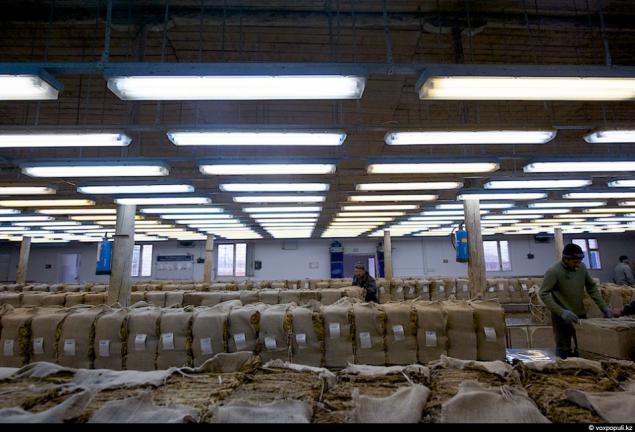

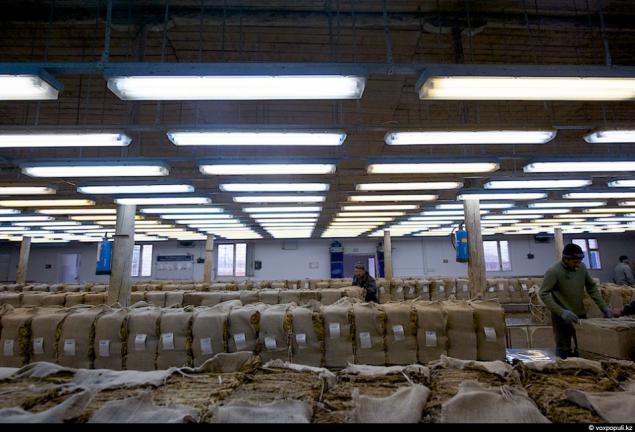

31. Next Tobacco gets on tape in temporary storage. Parallel input data for each bale in a common database system

32.

33. There is stockpiling of tobacco varieties. All details can be found on stickers

34. During the year, the total gets point for about 400 tons of tobacco

Source:

34 photos via vvoxpopuli

1. At Chilik farm tobacco leaves are dried naturally in the sun for 3-4 days. Drying is completed when the leaves dry up completely. Remove them in the morning when they are in otvolozhennom form, that is, when, after the wet night air leaves are soft and do not break

2. The cords connect to gavanki and hung on poles in the barn or under a roof. During drying tobacco, protect against wind and moisture

3. In this state, it is stored until ready to sorting

4. From the middle of September until the end of December to begin preparation for the delivery of tobacco. For this sort leaves under pressure and formed into bales. Pictured Haliskhan holding a bunch of future tobacco

5. indoors leaves carefully removed from the gavanok and transmit sorters

6. sorting involved both men and women. It is a process in which the work will be every

7. The cultivation of tobacco is mainly occupied by migrant workers from Kyrgyzstan who go home after putting in December

8. Tobacco is sorted into 6 grades. Grade determined by the color and quality of the leaves. One person can sort up to 60 kg of tobacco per day

9. When sorting tobacco leaves stacked in one direction, and after the press on a mechanical press in bales weighing 14 to 18 kg

10. Ready-wrapped bales of coarse linen cloth for easy transport. Tobacco company buys all the raw materials to the last leaf that provides the guaranteed sales. After the tobacco batch is ready, it is sent to the collection point for the company, "Philip Morris Kazakhstan»

11. According to its schedule brings the farmer ready raw material procurement item. During the delivery point for the day tobacco takes 800-1000 bp

12. Previously, the farmers had a lot more, but because of the economic crisis, their number decreased. According to statistics, in 2002 there were 4,700, but in 2011 had a total of 200

13. With one hectare a farmer collects from 1, 7 to 2, 5 tons of the crop

14.

15. Lease raw materials all together: and the farmer and his workers, who cultivated and harvested tobacco, to ensure transparency in future mutual. Recall that after six months of continuous work each employee can earn between 1,000 and 1,500 dollars

16. The bales are loaded on a cart to be delivered to the reception desk

17. Funnily enough, that the marketing of tobacco smoking is prohibited everywhere

18. A farmer in anticipation of the end of the season

19. Bale ready to test

20. The tobacco company is interested in good quality tobacco, so in every possible way to help farmers. For example, provide them with the necessary materials for production, it helps with seeds and advice on farming techniques, irrigation, seedlings, since the first withdrawal leaves

21. In Kazakhstan 6 tobacco companies, which share the market. The largest of them are JTI (44%), "Philip Morris Kazakhstan" (42%) and BAT (8-9%) (according to the newspaper "Course"), but uses only local raw materials, "Philip Morris»

22

23. The expert from the scanner determines the grade of tobacco that affects its value from 98 to 336 tenge per kilogram of tobacco

24. It is important to participate as a farmer and worker, to be seen at what price and what the quality of each bale is received

25. In the process of receiving each bale is opened in 6 places to the expert of the company could identify tobacco. Each bale is pasted barcode, which has all the information about what kind of variety, who the manufacturer, and the time and place of delivery of tobacco

26. Upon delivery, it is desirable to maintain the integrity of the tobacco leaf. In the sort of tobacco affect climatic conditions, proper care and soil parameters. It is estimated that in the south of Kazakhstan's tobacco grows better because of loamy soil, closer to Almaty, the soil is heavier and it affects the quality of

27. Samples of varieties of tobacco "Talgar 28", which is partly used in the production of local brands of cigarettes and exported to Russia, Ukraine, Czech Republic and Lithuania. For foreign brands of cigarettes that are manufactured in Kazakhstan, tobacco use other varieties. He brought specially from Europe

28. Laboratory assistant takes samples to determine moisture

29. The tobacco moisture content is determined for 7 minutes by evaporation and it must not exceed 18%. If the humidity exceeds the permitted limit, the farmers take tobacco back with them, dried and hand pile with the next batch

30. After all the tests stacks re-cross-linked to transport to the warehouse

31. Next Tobacco gets on tape in temporary storage. Parallel input data for each bale in a common database system

32.

33. There is stockpiling of tobacco varieties. All details can be found on stickers

34. During the year, the total gets point for about 400 tons of tobacco

Source: