1684

How do cigarettes in Belarus: report

Mindful of the fact that smoking is hazardous to health (as well as that in 2012, every Belarusian bought nearly 150 packets of cigarettes), we went to the Grodno Tobacco Factory "Neman". This company is in the top 6 of the largest taxpayers in the country, it has already passed through the thorns of modernization and, despite medical countermeasures, continues to build momentum. As in Belarus manufacture products of their own and foreign cigarette brands, what will the possible increase of tobacco use, and whether there will be self-extinguishing cigarettes in the country? This - in this photo essay.

Each year the world produced more than 6 trillion cigarettes, and the numbers are only growing. The gigantic scale of the industry, however, on a single plant is not felt. Modern production lines are compact and do not take up much space. But "firing bursts." Six, eight, ten thousand cigarettes per minute ... Who is the greatest?

75 photos and text

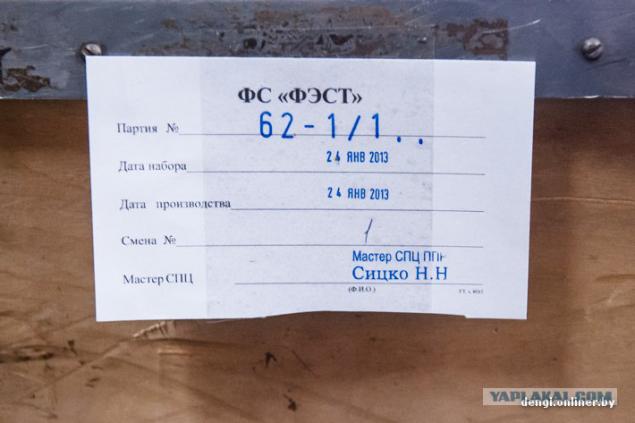

At the entrance of "Neman" employees show controller packs, which come on production. Cigarette millions and billions, but each - poduchetna. The output - control again. "We produce cigarettes, but smoking is allowed only at the factory in designated areas", - says Dmitry assistant general manager Chugai.

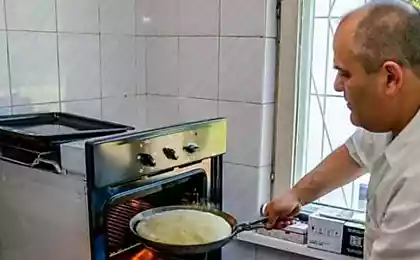

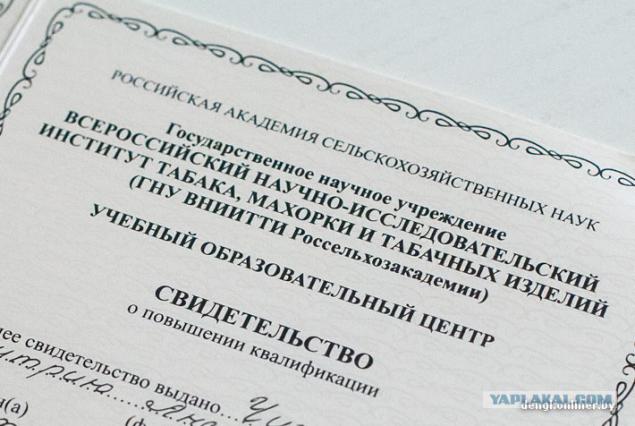

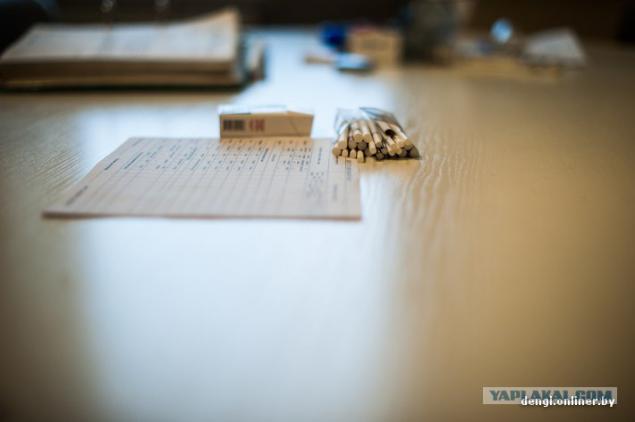

One of such places - the tasting room. It regularly gather tasters (they passed a special training course in the Krasnodar Research Institute of Tobacco, tobacco and tobacco products - it turns out there is such). They sit down at the table, puffed a cigarette filled with special tasting sheets. Every cigarette is assessed by several indicators: the aroma and taste of tobacco smoke, the force when tightening the fortress, flammability and others.

- We usually do 4-5 puffs, is no longer required, - says Dmitry Chugai. - To rest receptors, drink water or tea. For a tasting of smoked no more than 5 samples.

What smoking tasters (and hundreds of thousands of Belarusians)? Now look.

Raw

On the "Neman" carry out a complete production cycle. Schematically, it looks like this: purchase of raw materials, production of tobacco mixture (bags) filtropalochek directly the production of cigarettes.

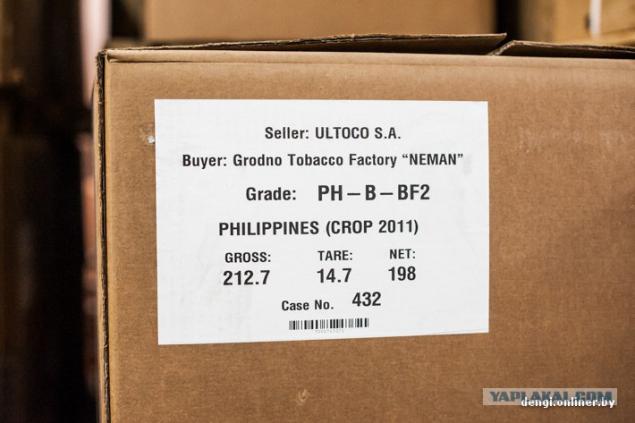

- Cigarettes vary in composition of the tobacco mixture: every 15 to 22 varieties of tobacco, which buys more than 20 countries around the world - say the experts. - The main volumes of products are made from sacks American Blend, which consists of tobacco "Virginia", "East", "Oriental", "Burley" with the addition of tobacco stems. 80% of cigarettes in our - own brands, 20% - contract manufacturing with British American Tobacco and Japan Tobacco International.

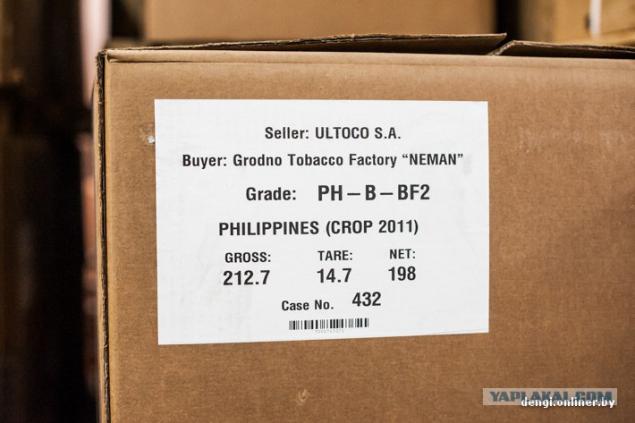

In this form, the raw material comes from abroad. In each box - your sortotipov tobacco.

04

05

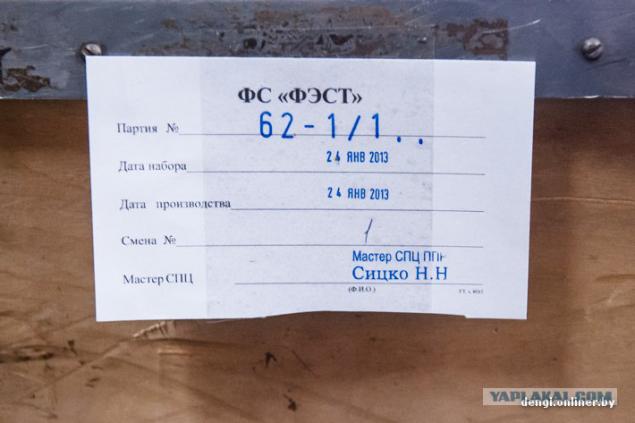

In stock form the party required for the manufacture of a particular cigarette brand. Their forms a blender. Pressed into "bundles" of tobacco is fed to a line input.

07

08

Recycling

On the assembly line - the tobacco to produce one of the brands of cigarettes Belarus. Upon receipt of raw materials to the shop and it is divided along two lines. One - Tobacco, the second - a vein (central part of the tobacco leaf), which is a part of almost any cut filler.

10

Line veins: Tobacco vein is first moistened, then goes to the binning in the silo, is sliced on the machine, then - on of expansion where it is treated with steam. Then it has "exploded" vein goes to a drying drum and the conveyor is for mixing with tobacco.

12

13

14

Line of raw tobacco: the processes largely similar. Tobacco "pile" is cut into four parts, followed by the processes sousirovaniya (for flavor), and air conditioning. Then - moisturizing, binning dryers.

16

17

18

By means of special weights tobacco vein and mixed in the desired ratio (depending on the brand of cigarettes), flavored. The result - a tobacco pouch, which is used in subsequent stages of production. The cigarettes "super-slim", experts say, in the vein of the bags not included.

Incidentally

- The country is fashionable to talk about import substitution. Grow in Belarus tobacco impossible? - We are interested.

- These experiments were carried out - told the experts. - In 2003-2004, the issues are selhozuniversitet Grodno. The results were not impressed: in our climatic zone, the plants do not have time to ripen. Raw gets low quality. Plus, there are no plants for further processing tobacco leaf and build them impractical - investments will not pay off. In the production of the same reasons used imported cigarette paper, foreign paper rim. With the collapse of the Union, there have been attempts to use for this purpose products "Gomeloboi," but the idea refused. Purchased abroad and special food flavors and sauces. Deliveries of materials made exclusively from well-known manufacturers.

Moving further along the processing chain. Straight to the filling station - are ready bag kept in containers. Organized its automatic feed into a cigarette shop.

20

Cigarette-cigarette shop

Do you know what a cigarette? The answer may be a few, but the best clean technology as follows: a "smoking article consisting of a segment of tobacco rod wrapped in cigarette paper, glued on the longitudinal seam, which is attached to the end of the filter tip." In other words, a seemingly simple product consists of several components.

The manufacturing process begins by loading the bags in the cigarette making machine.

22

23

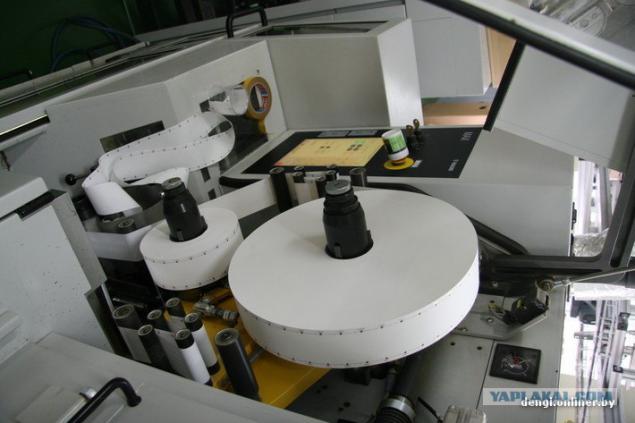

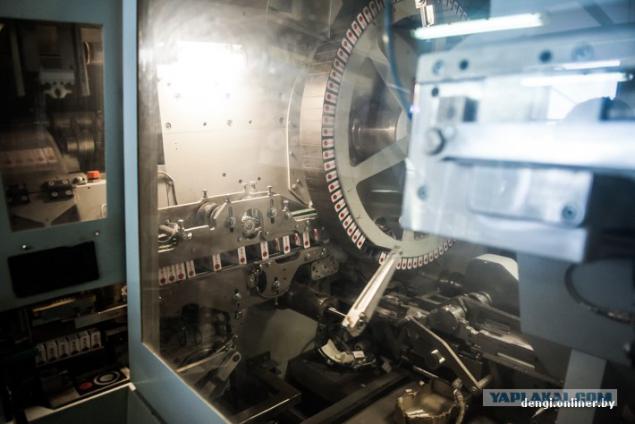

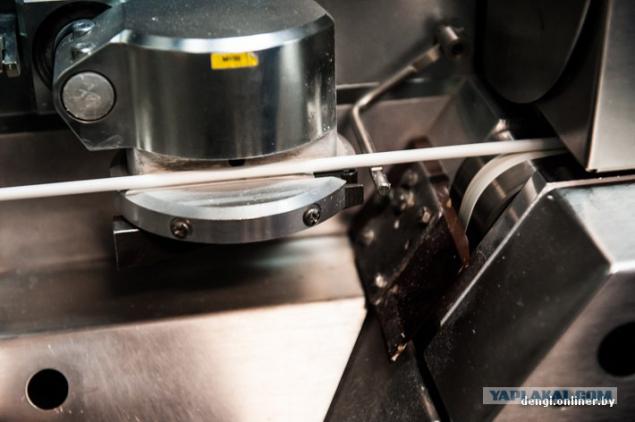

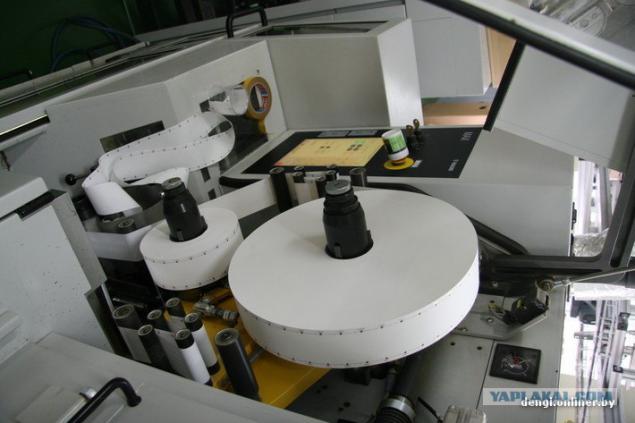

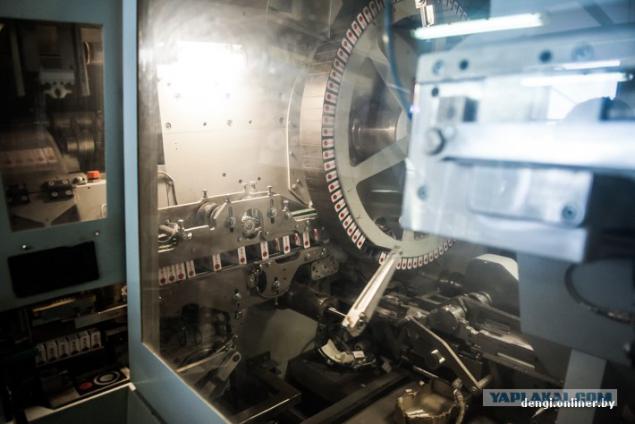

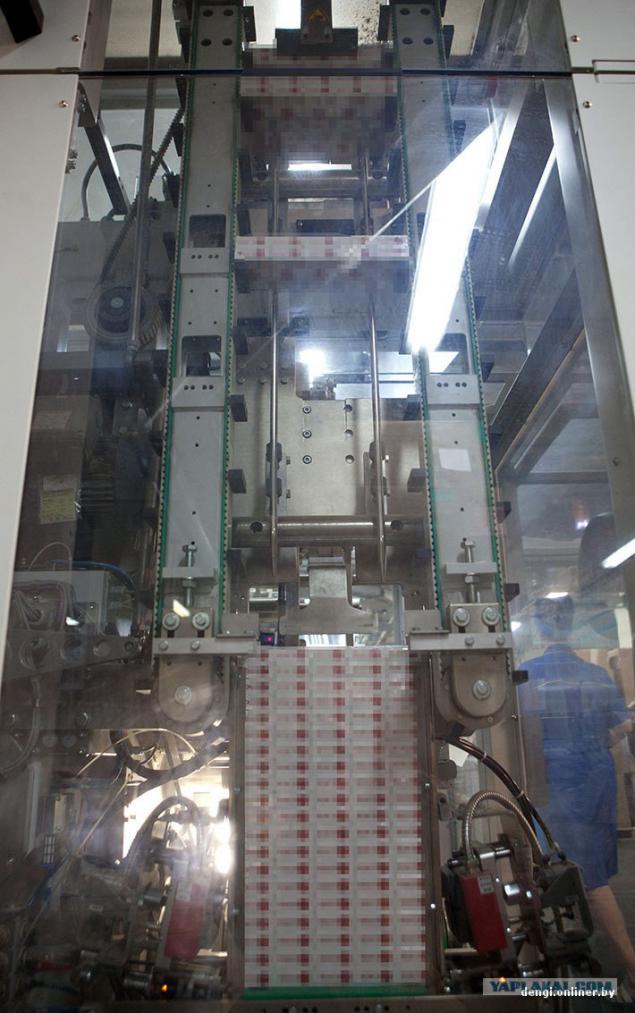

The next stage of the process - the formation of a tobacco. Automatically fed into the machine cigarette paper, and produced a so-called cigarette rod - long tube. Rod is cut into individual pieces in filtrosborochnoy car to the basis of the "join" filtropalochki. This set is glued tipping paper, and then cut into two parts. Get ready cigarette.

Shown in the photo can be just a few steps: the majority of manipulations are hidden inside the machine and occur at high speeds.

25

26

27

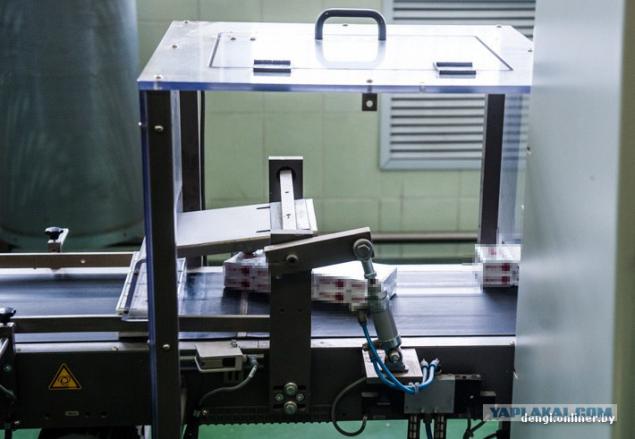

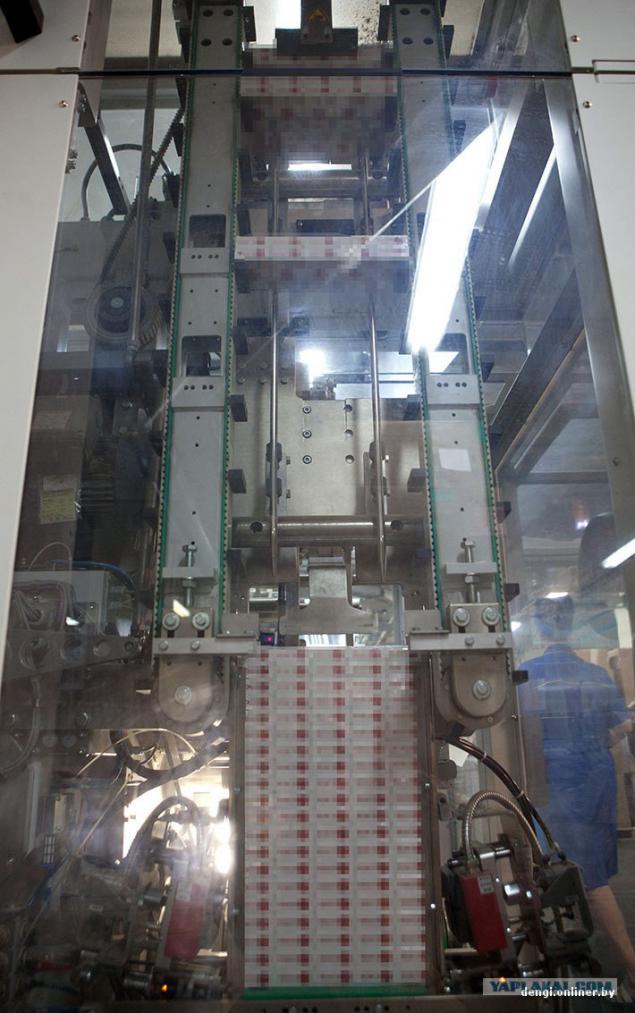

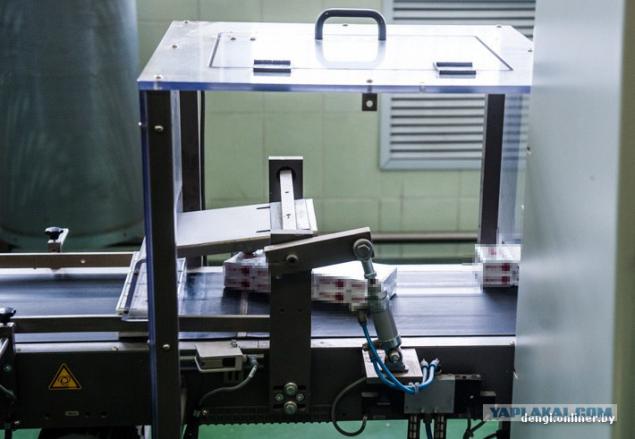

In the pipeline transit through the drive goes to the cigarette packaging machine - get the first pack and then blocks.

29

30

31

32

All processes are automated: the process of sticking labels, tear tape, the formation of "collar" sticker excise stamps, otselofanivanie.

34

35

36

37

38

39

40

41

42

43

44

45

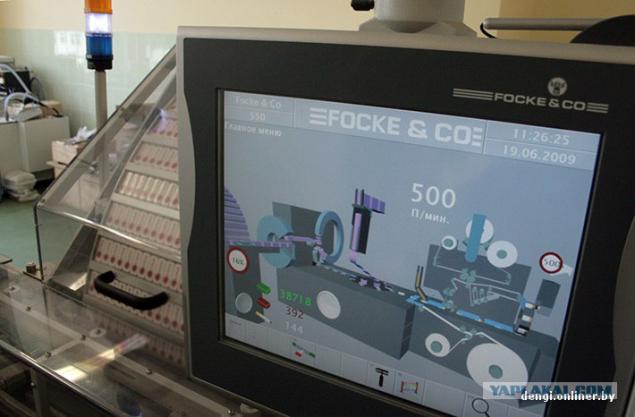

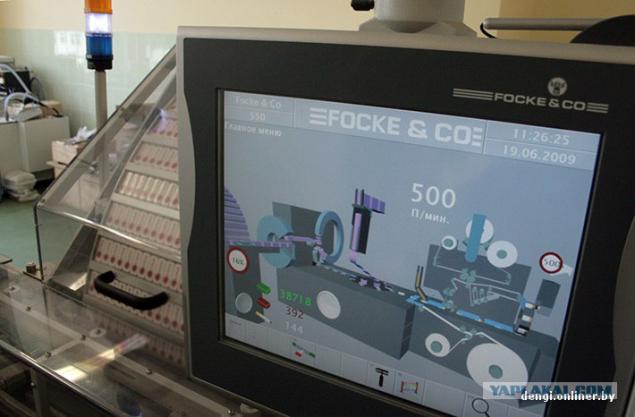

On the tape ready box "fly" to the warehouse. The thickness of this line - 10 000 cigarettes per minute ...

Incidentally

The most common complaint about the Belarusian producers why famous brands made by us, differ for the worse from their foreign counterparts?

- It's a stereotype, - says Dmitry Chugai. - All production is completely controlled by the specialists of foreign companies. Processes track their supervisors, senior managers come from Great Britain, Switzerland. Judge for yourself: in our factory set exactly the same equipment as in the factories of these companies worldwide. Our specialists have been trained abroad. Raw buy from the same suppliers. And the difference in taste can be explained simply. In different regions of the world cigarettes differ. If Russia and Belarus are similar tobacco blends, already Ukrainian cigarette smoking strange to us. Not to mention countries such as Greece or, for example, India.

47

- What's more profitable for the factory: to cultivate their own brands, or produce a license?

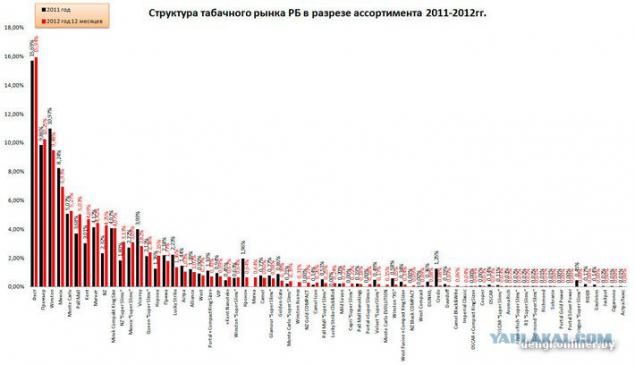

- Perform foreign brands it was particularly important when we started. In the early 2000s, the tobacco industry in the country there was chaos: 20% of the official import the same amount of smuggling that went from Russia, Ukraine to Europe and settled partly in Belarus. In Grodno factory while 80% of production capacity were loaded unfiltered cigarettes ... When the question arose about the development of the tobacco industry, it was decided not to reinvent the wheel and to start production of the famous brands of cigarettes, which usually prefers smoker. They offered to large multinational companies involved in the production, to invest in the development of the sector, having the opportunity to present on the market. Not all companies want this then - so we have the market of some well-known brands. However, it failed to establish cooperation. As a result, since 2006, been involved for almost 20 million euros of foreign investment in the form of grant sponsorship, while the state remains 100% stake in the factory, the modernization carried out, the experience was obtained. Famous brand was given the opportunity to download the power to restore the image. And to say today that it is cheaper? .. And then, and more. But in terms of positioning a bet you need to do on our own brand, but they are able to ensure stability. In the past year we have significantly stepped up exports, were able to enter the Russian market difficult ...

- But we are buying is still mostly imported ...

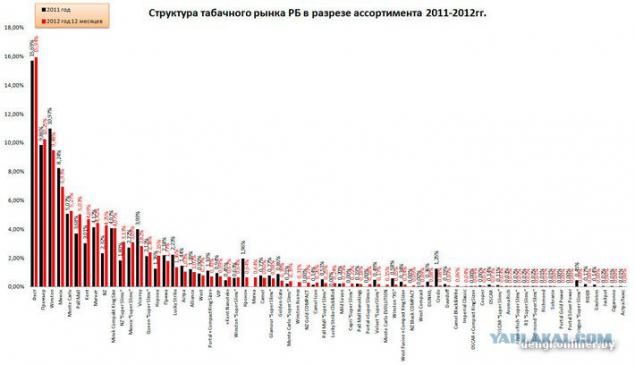

- This is also a stereotype. If you look at sales, the leaders - our own brand.

For its own brands "Neman" has established production filtropalochek - mono-acetate. They are made from chemical fibers. By the way, there is still releasing unfiltered cigarettes, but their market share is gradually falling.

50

51

52

53

54

Incidentally

Whether workers are afraid of the tobacco industry to competition from manufacturers of electronic cigarettes? Specialists of "Neman" convinced that this new trend will soon forget.

- Global manufacturers at the same time declare that they are ready to invest in the development of this alternative way of getting nicotine into the body, - says Dmitry Chugai. - The question is, before the end of e-cigarettes and their effects on the body have not been studied.

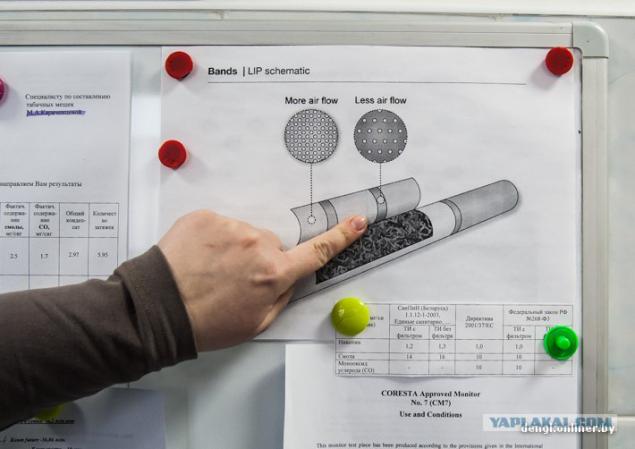

That "tell" smoking machine

Is it possible to make a safe cigarette? The question is rhetorical. However, to maintain the required standards manufacturers have to. Each line installed numerous control points, computer monitors compliance with the parameters of the recipe, appearance and many other indicators. The workshops provided dedusting, are air-conditioned.

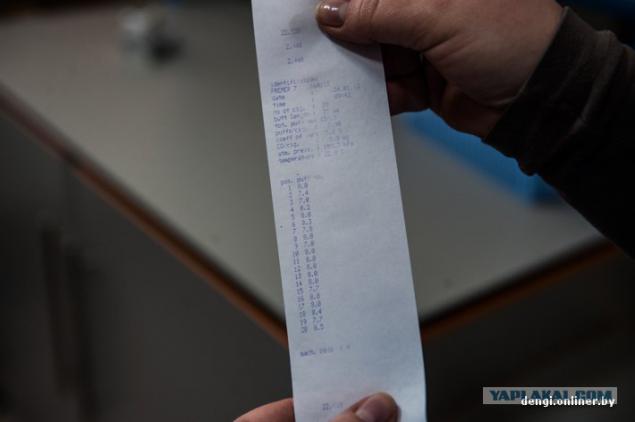

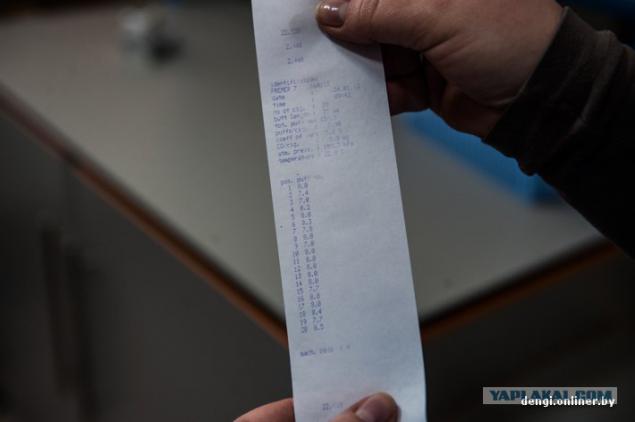

- All raw materials are accepted commissions held at this stage of the input control, - says head of the laboratory to control the production of Ioannina Petelchits. - Samples of finished cigarettes we weigh, measure their length, check the volume-elastic properties of tobacco and many other indicators.

56

57

58

59

Universal Testing Machine Control labels:

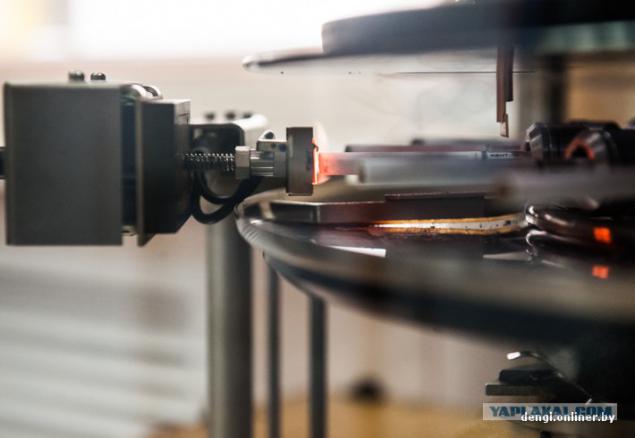

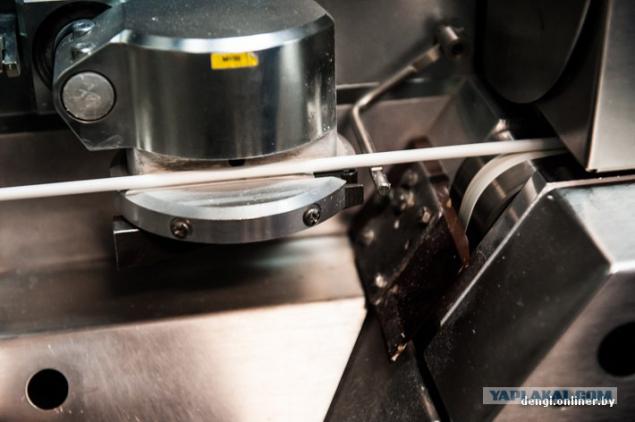

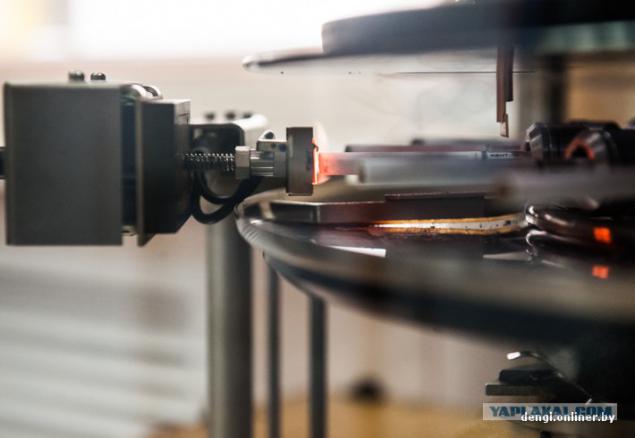

Safety indicators determines the smoking machine. With the help of periodic "prokurivayut" every brand of cigarettes.

- Prior to this, creating special conditions for samples: it is necessary that they have reached the equilibrium moisture content, - explains the laboratory staff.

63

64

Cigarette smoking is loaded into the machine, which simulates the tightness of the average smoker. The trap is laid for a smoke filter.

66

67

68

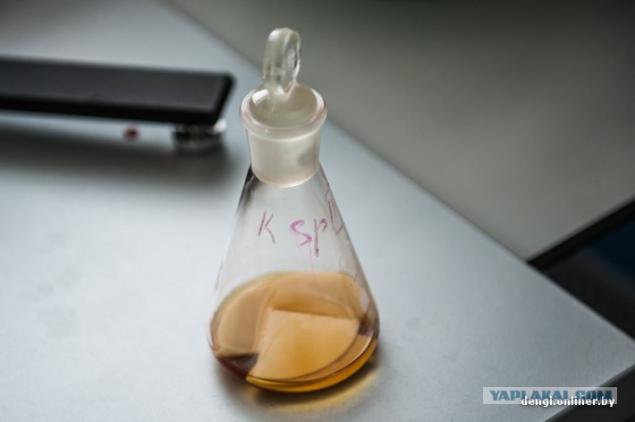

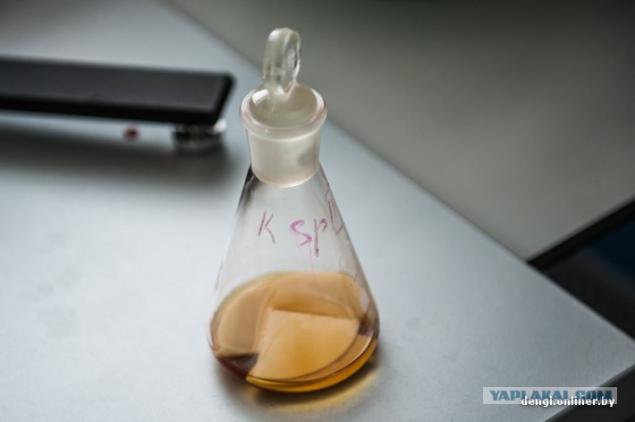

After "prokurivaniya" filter is soaked in a special extraction solution, and then the resultant liquid is checked by gas chromatography. After data reduction data specialists get the content of nicotine, tar and carbon monoxide in cigarettes. This is the data that lead on the pack.

70

71

Smoking machine worth about 180 thousand. Euro.

Incidentally

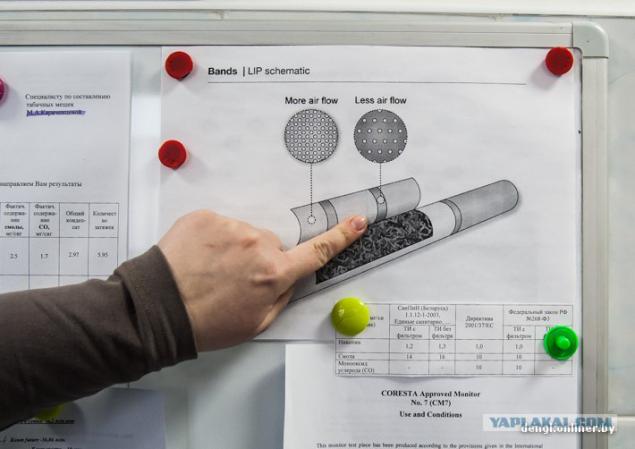

Some time ago, the Emergency Situations Ministry raised the issue that the Belarusian producers should go to so-called self-extinguishing cigarettes - in order to reduce the number of people killed in the fires through negligence. Such a rule already exists in the EU, and we have only to study the issue.

- We did tester, bought in France the necessary paper - says Janina Petelchits. - Conducted test. In 75% of cases the paper actually dies, but is still 25% ... In principle, we are ready to produce such cigarettes. But the paper is very expensive and would increase the cost of production up to 6 times.

73

As experts say, for 10 years the factory has reduced the average nicotine content per unit of private label products is almost 2 times: 1, 22 mg per cigarette in 2000 to 0, 7 mg in 2012.

"China will save us»

We do not just publish the opinions of physicians calling to raise the cost of cigarettes, making them inaccessible for the citizens of Belarus. What do people think about this producers?

- People quit smoking if a pack of cigarettes will cost 40 thousand.?

- I do not think - says Dmitry Chugai. - In this case, we "help" China, which now supplies 90% of the world of contraband cigarettes. By the way, they have learned to forge even our Belarusian brands! As soon as the Belarusian excise tax will be at or slightly more than the cost of the delivery of cigarettes from China to flood the smuggling.

- What impact on the value of the sales of cigarettes and a duty to "draw" on packs the terrible pictures of the effects of smoking?

- If you will oblige, will "draw!" Let only our printing to prepare. Otherwise you'll have to buy an expensive label for the currency. With regard to the effect of such images, then their own research, we have not performed. As world practice shows, the first stages of the people, on the contrary, they get cigarettes out of curiosity.

In 2012, the Grodno factory produced 26, 65 billion cigarettes - is 113, 9% compared to 2011. A record number of over 150 years of history of the company. Last year, the budget received from the "Neman" 1, 79 trillion rubles in taxes. In 2013, the GTP plans to transfer 3, 7 trillion rubles. Is it profitable to develop the state tobacco industry? The answer, I think, is obvious.

source

Source:

Each year the world produced more than 6 trillion cigarettes, and the numbers are only growing. The gigantic scale of the industry, however, on a single plant is not felt. Modern production lines are compact and do not take up much space. But "firing bursts." Six, eight, ten thousand cigarettes per minute ... Who is the greatest?

75 photos and text

At the entrance of "Neman" employees show controller packs, which come on production. Cigarette millions and billions, but each - poduchetna. The output - control again. "We produce cigarettes, but smoking is allowed only at the factory in designated areas", - says Dmitry assistant general manager Chugai.

One of such places - the tasting room. It regularly gather tasters (they passed a special training course in the Krasnodar Research Institute of Tobacco, tobacco and tobacco products - it turns out there is such). They sit down at the table, puffed a cigarette filled with special tasting sheets. Every cigarette is assessed by several indicators: the aroma and taste of tobacco smoke, the force when tightening the fortress, flammability and others.

- We usually do 4-5 puffs, is no longer required, - says Dmitry Chugai. - To rest receptors, drink water or tea. For a tasting of smoked no more than 5 samples.

What smoking tasters (and hundreds of thousands of Belarusians)? Now look.

Raw

On the "Neman" carry out a complete production cycle. Schematically, it looks like this: purchase of raw materials, production of tobacco mixture (bags) filtropalochek directly the production of cigarettes.

- Cigarettes vary in composition of the tobacco mixture: every 15 to 22 varieties of tobacco, which buys more than 20 countries around the world - say the experts. - The main volumes of products are made from sacks American Blend, which consists of tobacco "Virginia", "East", "Oriental", "Burley" with the addition of tobacco stems. 80% of cigarettes in our - own brands, 20% - contract manufacturing with British American Tobacco and Japan Tobacco International.

In this form, the raw material comes from abroad. In each box - your sortotipov tobacco.

04

05

In stock form the party required for the manufacture of a particular cigarette brand. Their forms a blender. Pressed into "bundles" of tobacco is fed to a line input.

07

08

Recycling

On the assembly line - the tobacco to produce one of the brands of cigarettes Belarus. Upon receipt of raw materials to the shop and it is divided along two lines. One - Tobacco, the second - a vein (central part of the tobacco leaf), which is a part of almost any cut filler.

10

Line veins: Tobacco vein is first moistened, then goes to the binning in the silo, is sliced on the machine, then - on of expansion where it is treated with steam. Then it has "exploded" vein goes to a drying drum and the conveyor is for mixing with tobacco.

12

13

14

Line of raw tobacco: the processes largely similar. Tobacco "pile" is cut into four parts, followed by the processes sousirovaniya (for flavor), and air conditioning. Then - moisturizing, binning dryers.

16

17

18

By means of special weights tobacco vein and mixed in the desired ratio (depending on the brand of cigarettes), flavored. The result - a tobacco pouch, which is used in subsequent stages of production. The cigarettes "super-slim", experts say, in the vein of the bags not included.

Incidentally

- The country is fashionable to talk about import substitution. Grow in Belarus tobacco impossible? - We are interested.

- These experiments were carried out - told the experts. - In 2003-2004, the issues are selhozuniversitet Grodno. The results were not impressed: in our climatic zone, the plants do not have time to ripen. Raw gets low quality. Plus, there are no plants for further processing tobacco leaf and build them impractical - investments will not pay off. In the production of the same reasons used imported cigarette paper, foreign paper rim. With the collapse of the Union, there have been attempts to use for this purpose products "Gomeloboi," but the idea refused. Purchased abroad and special food flavors and sauces. Deliveries of materials made exclusively from well-known manufacturers.

Moving further along the processing chain. Straight to the filling station - are ready bag kept in containers. Organized its automatic feed into a cigarette shop.

20

Cigarette-cigarette shop

Do you know what a cigarette? The answer may be a few, but the best clean technology as follows: a "smoking article consisting of a segment of tobacco rod wrapped in cigarette paper, glued on the longitudinal seam, which is attached to the end of the filter tip." In other words, a seemingly simple product consists of several components.

The manufacturing process begins by loading the bags in the cigarette making machine.

22

23

The next stage of the process - the formation of a tobacco. Automatically fed into the machine cigarette paper, and produced a so-called cigarette rod - long tube. Rod is cut into individual pieces in filtrosborochnoy car to the basis of the "join" filtropalochki. This set is glued tipping paper, and then cut into two parts. Get ready cigarette.

Shown in the photo can be just a few steps: the majority of manipulations are hidden inside the machine and occur at high speeds.

25

26

27

In the pipeline transit through the drive goes to the cigarette packaging machine - get the first pack and then blocks.

29

30

31

32

All processes are automated: the process of sticking labels, tear tape, the formation of "collar" sticker excise stamps, otselofanivanie.

34

35

36

37

38

39

40

41

42

43

44

45

On the tape ready box "fly" to the warehouse. The thickness of this line - 10 000 cigarettes per minute ...

Incidentally

The most common complaint about the Belarusian producers why famous brands made by us, differ for the worse from their foreign counterparts?

- It's a stereotype, - says Dmitry Chugai. - All production is completely controlled by the specialists of foreign companies. Processes track their supervisors, senior managers come from Great Britain, Switzerland. Judge for yourself: in our factory set exactly the same equipment as in the factories of these companies worldwide. Our specialists have been trained abroad. Raw buy from the same suppliers. And the difference in taste can be explained simply. In different regions of the world cigarettes differ. If Russia and Belarus are similar tobacco blends, already Ukrainian cigarette smoking strange to us. Not to mention countries such as Greece or, for example, India.

47

- What's more profitable for the factory: to cultivate their own brands, or produce a license?

- Perform foreign brands it was particularly important when we started. In the early 2000s, the tobacco industry in the country there was chaos: 20% of the official import the same amount of smuggling that went from Russia, Ukraine to Europe and settled partly in Belarus. In Grodno factory while 80% of production capacity were loaded unfiltered cigarettes ... When the question arose about the development of the tobacco industry, it was decided not to reinvent the wheel and to start production of the famous brands of cigarettes, which usually prefers smoker. They offered to large multinational companies involved in the production, to invest in the development of the sector, having the opportunity to present on the market. Not all companies want this then - so we have the market of some well-known brands. However, it failed to establish cooperation. As a result, since 2006, been involved for almost 20 million euros of foreign investment in the form of grant sponsorship, while the state remains 100% stake in the factory, the modernization carried out, the experience was obtained. Famous brand was given the opportunity to download the power to restore the image. And to say today that it is cheaper? .. And then, and more. But in terms of positioning a bet you need to do on our own brand, but they are able to ensure stability. In the past year we have significantly stepped up exports, were able to enter the Russian market difficult ...

- But we are buying is still mostly imported ...

- This is also a stereotype. If you look at sales, the leaders - our own brand.

For its own brands "Neman" has established production filtropalochek - mono-acetate. They are made from chemical fibers. By the way, there is still releasing unfiltered cigarettes, but their market share is gradually falling.

50

51

52

53

54

Incidentally

Whether workers are afraid of the tobacco industry to competition from manufacturers of electronic cigarettes? Specialists of "Neman" convinced that this new trend will soon forget.

- Global manufacturers at the same time declare that they are ready to invest in the development of this alternative way of getting nicotine into the body, - says Dmitry Chugai. - The question is, before the end of e-cigarettes and their effects on the body have not been studied.

That "tell" smoking machine

Is it possible to make a safe cigarette? The question is rhetorical. However, to maintain the required standards manufacturers have to. Each line installed numerous control points, computer monitors compliance with the parameters of the recipe, appearance and many other indicators. The workshops provided dedusting, are air-conditioned.

- All raw materials are accepted commissions held at this stage of the input control, - says head of the laboratory to control the production of Ioannina Petelchits. - Samples of finished cigarettes we weigh, measure their length, check the volume-elastic properties of tobacco and many other indicators.

56

57

58

59

Universal Testing Machine Control labels:

Safety indicators determines the smoking machine. With the help of periodic "prokurivayut" every brand of cigarettes.

- Prior to this, creating special conditions for samples: it is necessary that they have reached the equilibrium moisture content, - explains the laboratory staff.

63

64

Cigarette smoking is loaded into the machine, which simulates the tightness of the average smoker. The trap is laid for a smoke filter.

66

67

68

After "prokurivaniya" filter is soaked in a special extraction solution, and then the resultant liquid is checked by gas chromatography. After data reduction data specialists get the content of nicotine, tar and carbon monoxide in cigarettes. This is the data that lead on the pack.

70

71

Smoking machine worth about 180 thousand. Euro.

Incidentally

Some time ago, the Emergency Situations Ministry raised the issue that the Belarusian producers should go to so-called self-extinguishing cigarettes - in order to reduce the number of people killed in the fires through negligence. Such a rule already exists in the EU, and we have only to study the issue.

- We did tester, bought in France the necessary paper - says Janina Petelchits. - Conducted test. In 75% of cases the paper actually dies, but is still 25% ... In principle, we are ready to produce such cigarettes. But the paper is very expensive and would increase the cost of production up to 6 times.

73

As experts say, for 10 years the factory has reduced the average nicotine content per unit of private label products is almost 2 times: 1, 22 mg per cigarette in 2000 to 0, 7 mg in 2012.

"China will save us»

We do not just publish the opinions of physicians calling to raise the cost of cigarettes, making them inaccessible for the citizens of Belarus. What do people think about this producers?

- People quit smoking if a pack of cigarettes will cost 40 thousand.?

- I do not think - says Dmitry Chugai. - In this case, we "help" China, which now supplies 90% of the world of contraband cigarettes. By the way, they have learned to forge even our Belarusian brands! As soon as the Belarusian excise tax will be at or slightly more than the cost of the delivery of cigarettes from China to flood the smuggling.

- What impact on the value of the sales of cigarettes and a duty to "draw" on packs the terrible pictures of the effects of smoking?

- If you will oblige, will "draw!" Let only our printing to prepare. Otherwise you'll have to buy an expensive label for the currency. With regard to the effect of such images, then their own research, we have not performed. As world practice shows, the first stages of the people, on the contrary, they get cigarettes out of curiosity.

In 2012, the Grodno factory produced 26, 65 billion cigarettes - is 113, 9% compared to 2011. A record number of over 150 years of history of the company. Last year, the budget received from the "Neman" 1, 79 trillion rubles in taxes. In 2013, the GTP plans to transfer 3, 7 trillion rubles. Is it profitable to develop the state tobacco industry? The answer, I think, is obvious.

source

Source: