738

Production ring

Thus, almost the entire manufacturing process. Will be 32 photos, please do not break.

In stock we have here is a sapphire in almost 15 carats (the stone of the customer), and that the customer wants to ring.

I develop a sketch. Many have chosen this option.

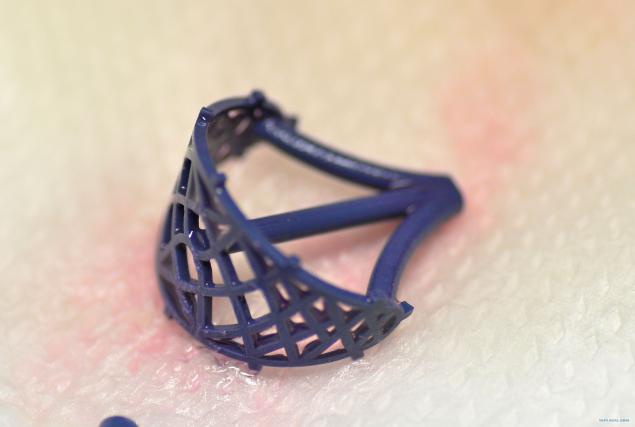

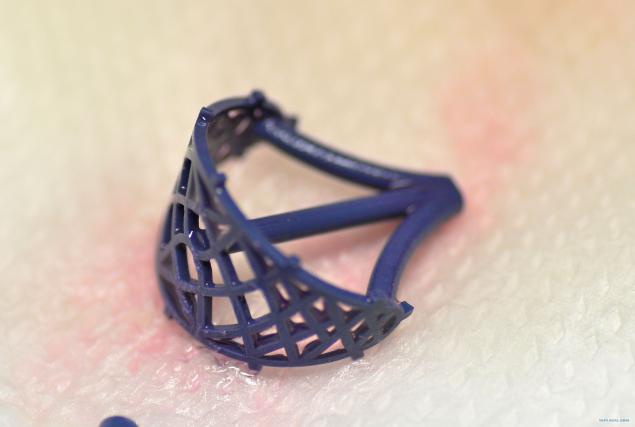

The Rhinoceros 4.0 build 3D model of our ring, I place the sprues and send to print.

Shaitan solidscape machine prints a couple of days a ring of wax.

...

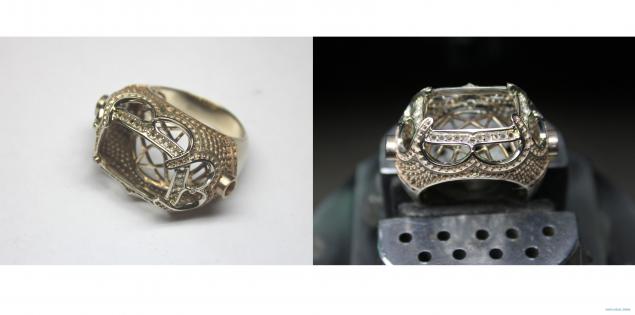

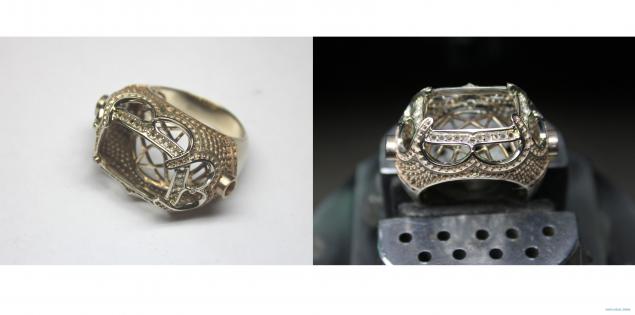

After casting, the details become a kind of ring (white gold 750)

I will not describe the casting process, it is not very interesting =)

Sprues ruthlessly saw off

...

Result

GRINDER polish grid using different skins / gum / brushes, etc.

Tool

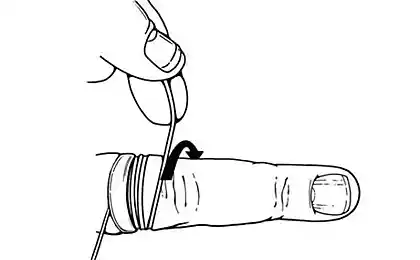

To grind the cells in the grid, it is necessary to insert a strip of skin jigsaw of different factions. Then polish. On the net out almost daily.

Inside the ring is similar and all were ground vypolirovyvayu to shine.

Done

Now you can weld with a net basis. Be sure to boil the flux to the solder flowed and to polishing is darkened (boric + drill 50 to 50)

Pike

After soldering, be sure to boil in the bleach, to remove flux residue. (acid-free chill)

GRINDER polish actually result

They were brought into the ring Assay Office, where we put the sample. At this time I prepared for soldering tip.

Junction

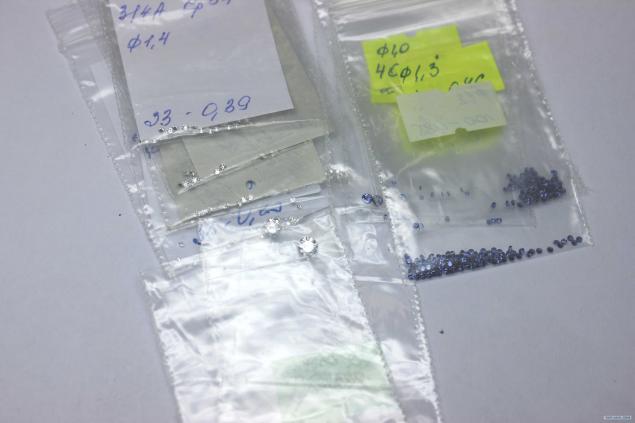

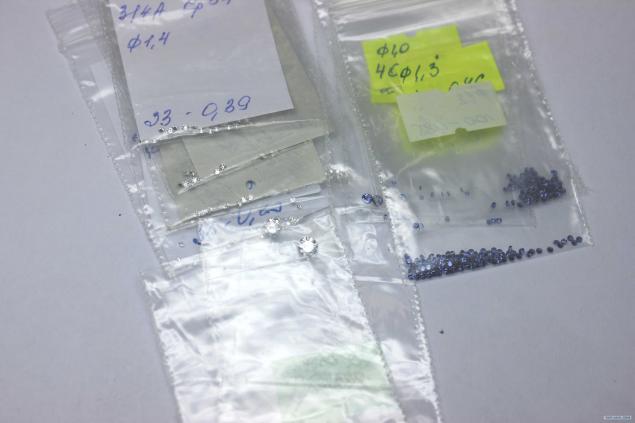

You can start the most interesting - tack. The stones - sapphires and diamonds.

Tool tack. Various graver, kornevertki, scraper, etc.

Various drills, cutters

sverlyshki

Secure the top

I begin to fix sapphires and diamonds large

...

Fasten the central stone and the remnants of diamonds. Almost everything is ready, it remains the heart and polirnut otrodirovat (the product covered with a thin layer of rhodium in

a few microns to white gold has become a normal white color)

...

Rhodium Plated. All products are white rhodium, and where black sapphires. That's all done. You can give the customer

...

...

And here is my bench, wondering if someone suddenly (after cleaning of course) That's all, thank you all for your attention

Source:

In stock we have here is a sapphire in almost 15 carats (the stone of the customer), and that the customer wants to ring.

I develop a sketch. Many have chosen this option.

The Rhinoceros 4.0 build 3D model of our ring, I place the sprues and send to print.

Shaitan solidscape machine prints a couple of days a ring of wax.

...

After casting, the details become a kind of ring (white gold 750)

I will not describe the casting process, it is not very interesting =)

Sprues ruthlessly saw off

...

Result

GRINDER polish grid using different skins / gum / brushes, etc.

Tool

To grind the cells in the grid, it is necessary to insert a strip of skin jigsaw of different factions. Then polish. On the net out almost daily.

Inside the ring is similar and all were ground vypolirovyvayu to shine.

Done

Now you can weld with a net basis. Be sure to boil the flux to the solder flowed and to polishing is darkened (boric + drill 50 to 50)

Pike

After soldering, be sure to boil in the bleach, to remove flux residue. (acid-free chill)

GRINDER polish actually result

They were brought into the ring Assay Office, where we put the sample. At this time I prepared for soldering tip.

Junction

You can start the most interesting - tack. The stones - sapphires and diamonds.

Tool tack. Various graver, kornevertki, scraper, etc.

Various drills, cutters

sverlyshki

Secure the top

I begin to fix sapphires and diamonds large

...

Fasten the central stone and the remnants of diamonds. Almost everything is ready, it remains the heart and polirnut otrodirovat (the product covered with a thin layer of rhodium in

a few microns to white gold has become a normal white color)

...

Rhodium Plated. All products are white rhodium, and where black sapphires. That's all done. You can give the customer

...

...

And here is my bench, wondering if someone suddenly (after cleaning of course) That's all, thank you all for your attention

Source: