759

Putting LED floodlight on the knee

Today I will write, how to become a Russian manufacturer of LED equipment and of what constitutes a product price. It will be a little chaotic text and a couple of dozen pictures. The end will outline.

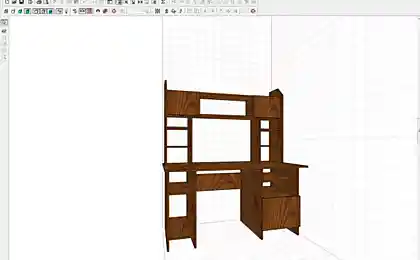

It konstruktor.V It includes details of the case, the driver and diode array. Housing purchased in China. There is already running a copy machine for their production and the housing is cheap. Chinese body paint sucks, so we repaint them under our usloviya.Protsess painting I did not take off, but in reality it is a common polymer coating. Such coloring distinguishes our spotlight from the Chinese and the diode shirpotreba.Drayver bought in Taiwan.

On the inside of the body Apply thermal grease. Grease improve heat transfer between the diode and the housing.

Take a good thermal paste. It will not stiffen from heat and cool the diode is good.

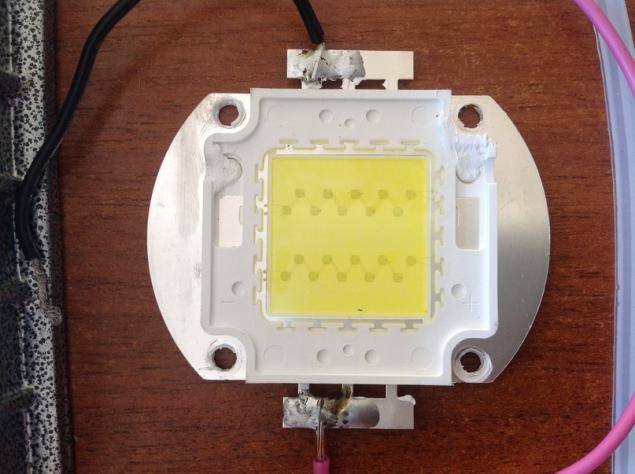

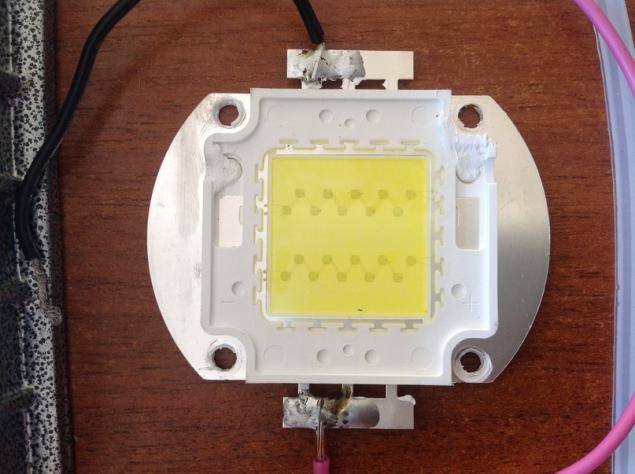

This matrix itself. The manufacturer claims that it collects crystals by American company BRIDGELUX. Crystals of these pure and luminous efficiency of such a matrix yarkie.Nominalnaya 2200 lumens.

Lumen, lumen, lum - is a measure of the luminous flux. Normal bulb 40 W power outputs from 400 lyumen.Eto means that its efficiency of 10 lumens to watt. This is the diode produces 110 lumens with a 1 watt. However, the reality is slightly smaller, but more on that later.

Since the white light produced by diode transmission of blue light (it is just the most intense) through the yellow phosphor manufacturer has paid special attention to him. If the phosphor is poor quality, it loses its properties over time. In fact, it is evident that the diode begins to "sinit." Blue partially passes through the phosphor and then it seems that the world has become cold. Pay attention to the Chinese running lights from cars - they shine blue light.

Firmly push the diode to the surface. Grease is very easily soiled, watching not to smear the surface of the diode.

Remove the excess paste and fasten to the body diode.

The peculiarity of this diode - 20 odnovatnyh points connected with gold thread. Some collectors manufacturers put similar diodes with 16 points and declare both 20 cotton. The price of such a diode is lower, but the light it worse.

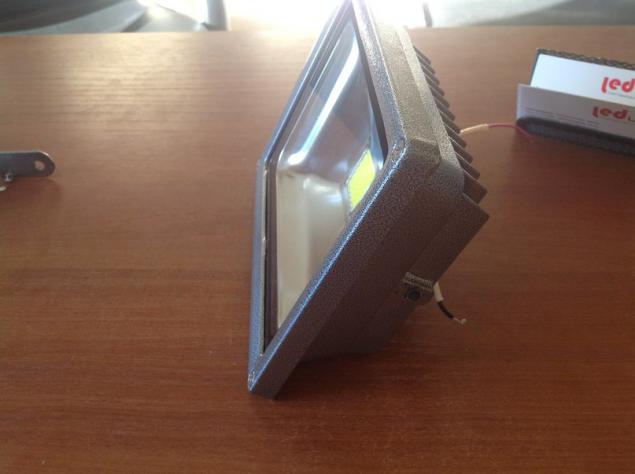

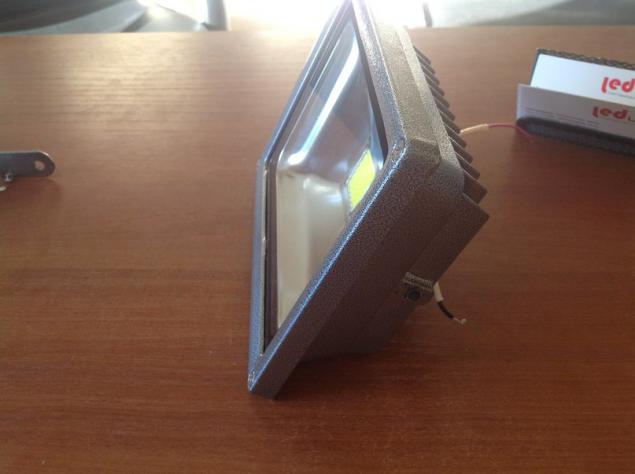

Close the top decorative reflectors. In fact, it is necessary only for beauty. The diode itself shines with an angle of 120-140 degrees

The grooves housing gasket set. I use silicone. They are durable and are not afraid of frost.

Presses laying glass

Luminous part of the projector is ready!

Begin to gather the power module. Dress silicone rings. They need to seal the wires.

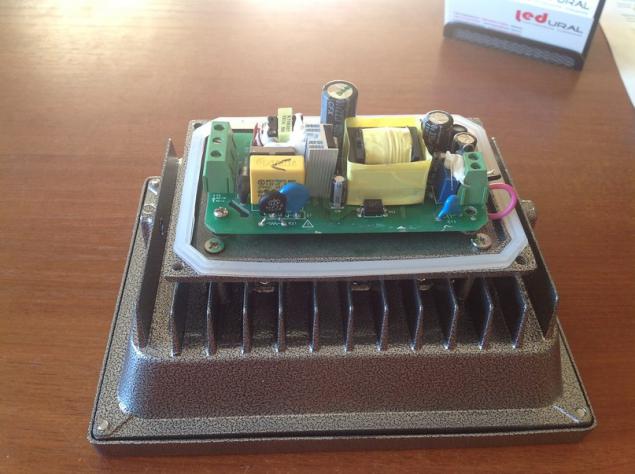

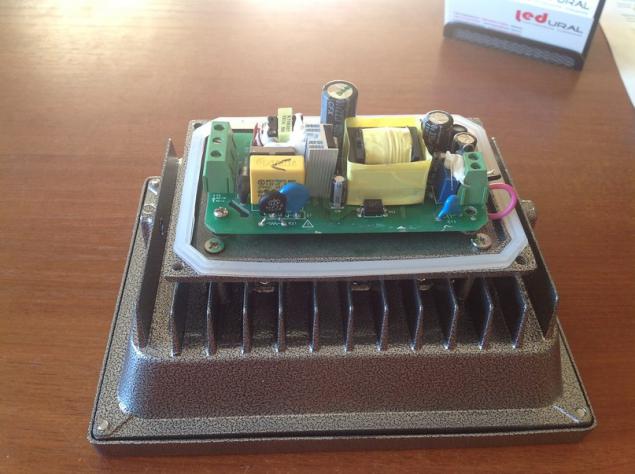

Install the bottom cover compartment for the driver and the driver itself.

Drivers great mnozhestvo.Chem complicated driver, the more live diode. This driver stabilizes the voltage and current, even if the mains voltage is jumping from 80 to 280 volts. In the glow of this will not be displayed.

We clean the PVA cable

According to the inscriptions on the board, connected to terminal block. Incidentally, the block is unlike professional drivers. The wire can be connected directly and the desired section. The Chinese consumer goods are all soldered and filled.

Cylindrical section chosen because it is more tightly sits in slot

Spotlight extends to sozdatelyu.Ostalos fasten the mounting arc and check for serviceability.

Let there be light!

I did not disperse diodes current sacrificing brightness in favor of longevity. However, initially using a bright diodes. Roughly at the diode supply 30%.

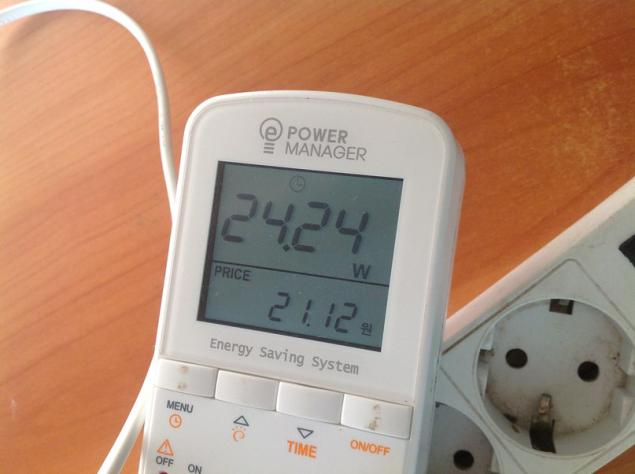

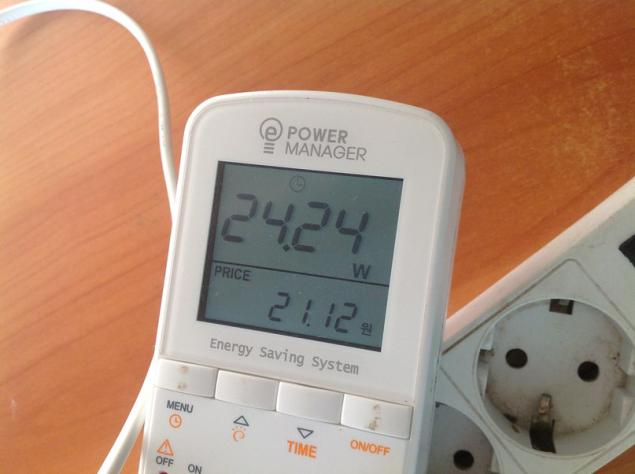

Below is the cosine of φ (phi) .value more than 0.9 are considered to be an excellent indicator.

Low power factor also leads to an increase in electricity losses in the electric network.

Since the projectors to be used at high altitude, they have to be reliable.

Together with the driver Spotlight eats 24 watts.

On the way out we got a 24W LED spotlight and a luminous flux of about 2,000 lumens. Assembled spotlight, as the practice is fairly low light degradation (about 5% per year). Its price is certainly higher than the Chinese consumer goods, therefore, it is used where reliability appreciated.

That's all I wanted to say. Thank you for your attention)

Source:

It konstruktor.V It includes details of the case, the driver and diode array. Housing purchased in China. There is already running a copy machine for their production and the housing is cheap. Chinese body paint sucks, so we repaint them under our usloviya.Protsess painting I did not take off, but in reality it is a common polymer coating. Such coloring distinguishes our spotlight from the Chinese and the diode shirpotreba.Drayver bought in Taiwan.

On the inside of the body Apply thermal grease. Grease improve heat transfer between the diode and the housing.

Take a good thermal paste. It will not stiffen from heat and cool the diode is good.

This matrix itself. The manufacturer claims that it collects crystals by American company BRIDGELUX. Crystals of these pure and luminous efficiency of such a matrix yarkie.Nominalnaya 2200 lumens.

Lumen, lumen, lum - is a measure of the luminous flux. Normal bulb 40 W power outputs from 400 lyumen.Eto means that its efficiency of 10 lumens to watt. This is the diode produces 110 lumens with a 1 watt. However, the reality is slightly smaller, but more on that later.

Since the white light produced by diode transmission of blue light (it is just the most intense) through the yellow phosphor manufacturer has paid special attention to him. If the phosphor is poor quality, it loses its properties over time. In fact, it is evident that the diode begins to "sinit." Blue partially passes through the phosphor and then it seems that the world has become cold. Pay attention to the Chinese running lights from cars - they shine blue light.

Firmly push the diode to the surface. Grease is very easily soiled, watching not to smear the surface of the diode.

Remove the excess paste and fasten to the body diode.

The peculiarity of this diode - 20 odnovatnyh points connected with gold thread. Some collectors manufacturers put similar diodes with 16 points and declare both 20 cotton. The price of such a diode is lower, but the light it worse.

Close the top decorative reflectors. In fact, it is necessary only for beauty. The diode itself shines with an angle of 120-140 degrees

The grooves housing gasket set. I use silicone. They are durable and are not afraid of frost.

Presses laying glass

Luminous part of the projector is ready!

Begin to gather the power module. Dress silicone rings. They need to seal the wires.

Install the bottom cover compartment for the driver and the driver itself.

Drivers great mnozhestvo.Chem complicated driver, the more live diode. This driver stabilizes the voltage and current, even if the mains voltage is jumping from 80 to 280 volts. In the glow of this will not be displayed.

We clean the PVA cable

According to the inscriptions on the board, connected to terminal block. Incidentally, the block is unlike professional drivers. The wire can be connected directly and the desired section. The Chinese consumer goods are all soldered and filled.

Cylindrical section chosen because it is more tightly sits in slot

Spotlight extends to sozdatelyu.Ostalos fasten the mounting arc and check for serviceability.

Let there be light!

I did not disperse diodes current sacrificing brightness in favor of longevity. However, initially using a bright diodes. Roughly at the diode supply 30%.

Below is the cosine of φ (phi) .value more than 0.9 are considered to be an excellent indicator.

Low power factor also leads to an increase in electricity losses in the electric network.

Since the projectors to be used at high altitude, they have to be reliable.

Together with the driver Spotlight eats 24 watts.

On the way out we got a 24W LED spotlight and a luminous flux of about 2,000 lumens. Assembled spotlight, as the practice is fairly low light degradation (about 5% per year). Its price is certainly higher than the Chinese consumer goods, therefore, it is used where reliability appreciated.

That's all I wanted to say. Thank you for your attention)

Source: