762

Strange cars in Moscow

That's because it's a miracle !! ?? The first time I see such. But if you dig?

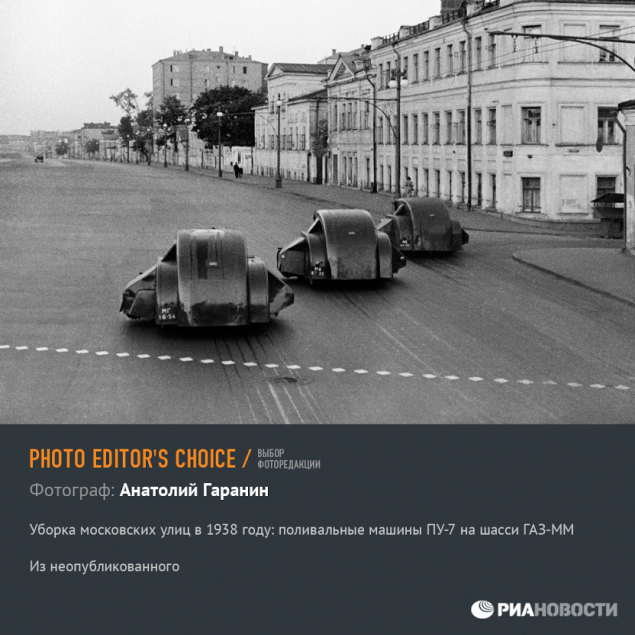

6 Photo © RIA via infoglaz

But with such an angle more than usual:

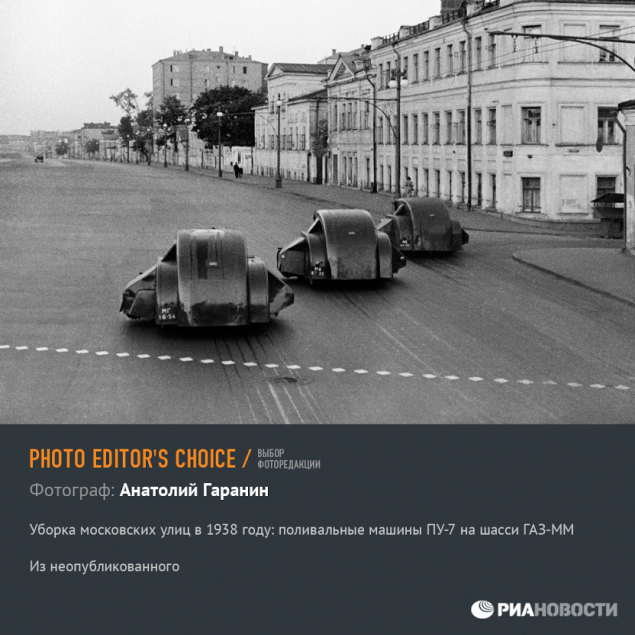

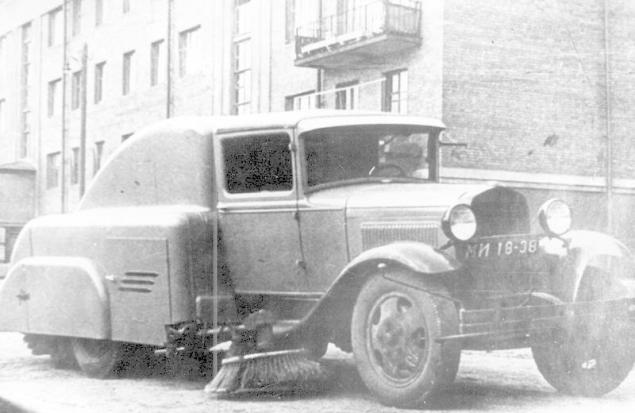

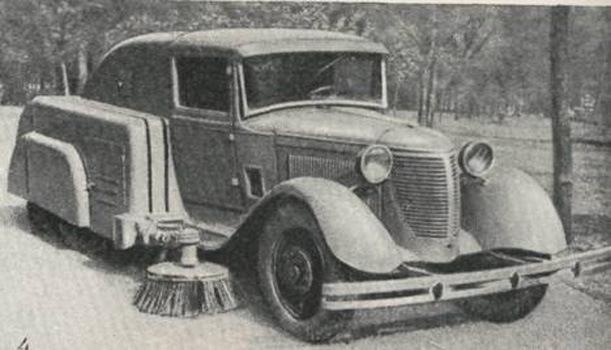

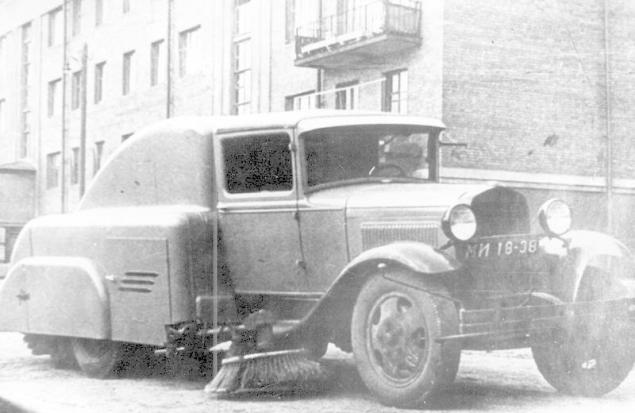

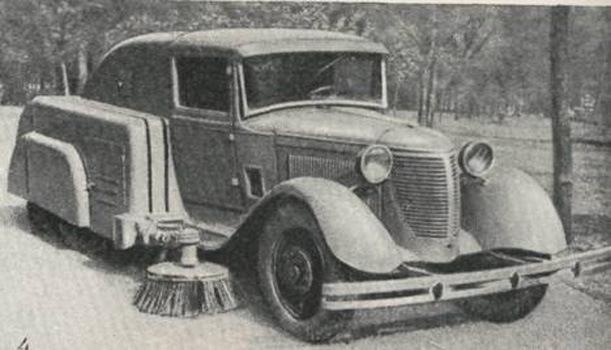

The first domestic sweepers were designed on the basis of GAZ-AA / GAZ-MM

The design of the vehicle PU-7 on the GAZ-MM had a tank of process water, brushes and containers for the collected debris. Before sweeping a compulsory moistening of the road to fine dust particles were not raised in the air. The design of PU-7 the mid-1930s with the passage of time changed the chassis and names.

In the mid-twentieth century, the most popular were a series of cars GAZ-51, which GAZ started to make in December 1945 and launched into mass production in June 1946. Thanks to good technical performance, high performance and excellence design of this car was the classic base for the creation of various types of specialized equipment for the maintenance of urban areas.

One of the most common modifications of GAZ-51 was its transformation into a truck-car ubrochny PU-20 road sweeper-brush machine PU-8 gritter IP-4M, pneumatic Sweeper PU-4.

The design of the vehicle PU-20 (Figure 4.) Enables sweeping the sidewalk directly from the end, thanks to the two brushes located on the sides of the machine.

Sweep the elements of the machine: chute (side) and the rear brush it was quick, greatly reducing the time to replace them.

Fig. 4. Model pavement machine PU-20

Articulated spring structure trough brushes allow you to set them at an angle to the road surface. Chain conveyor allowed to file sweeps debris from the brush back into the hopper. Trough brush direct estimates of the center of the machine, where it is thrown the main brush onto the conveyor and into the bunker. Humidification system prevents the formation of dust during the operation of the machine. It had two tanks connected together, the filter sump, the water pump and the injector located under the front bumper of the vehicle.

All the organs of IP-20 were placed in the compact all-welded body. The bunker was an integral part. Removing debris from the hopper was carried out by opening the hatches (located on the sides of the hopper), from which spill estimates. One such machine per working day, with an average width of streets swept up to 23 km.

Source:

6 Photo © RIA via infoglaz

But with such an angle more than usual:

The first domestic sweepers were designed on the basis of GAZ-AA / GAZ-MM

The design of the vehicle PU-7 on the GAZ-MM had a tank of process water, brushes and containers for the collected debris. Before sweeping a compulsory moistening of the road to fine dust particles were not raised in the air. The design of PU-7 the mid-1930s with the passage of time changed the chassis and names.

In the mid-twentieth century, the most popular were a series of cars GAZ-51, which GAZ started to make in December 1945 and launched into mass production in June 1946. Thanks to good technical performance, high performance and excellence design of this car was the classic base for the creation of various types of specialized equipment for the maintenance of urban areas.

One of the most common modifications of GAZ-51 was its transformation into a truck-car ubrochny PU-20 road sweeper-brush machine PU-8 gritter IP-4M, pneumatic Sweeper PU-4.

The design of the vehicle PU-20 (Figure 4.) Enables sweeping the sidewalk directly from the end, thanks to the two brushes located on the sides of the machine.

Sweep the elements of the machine: chute (side) and the rear brush it was quick, greatly reducing the time to replace them.

Fig. 4. Model pavement machine PU-20

Articulated spring structure trough brushes allow you to set them at an angle to the road surface. Chain conveyor allowed to file sweeps debris from the brush back into the hopper. Trough brush direct estimates of the center of the machine, where it is thrown the main brush onto the conveyor and into the bunker. Humidification system prevents the formation of dust during the operation of the machine. It had two tanks connected together, the filter sump, the water pump and the injector located under the front bumper of the vehicle.

All the organs of IP-20 were placed in the compact all-welded body. The bunker was an integral part. Removing debris from the hopper was carried out by opening the hatches (located on the sides of the hopper), from which spill estimates. One such machine per working day, with an average width of streets swept up to 23 km.

Source: