5658

Plaster head with his own hands

Plaster head, if anyone knows, it is primarily for the benefit of academic drawing, and of photographers are often used in training. Many use the course just for the interior ... Now I will tell you and show you how they are born ...

Many people think that they are made from plaster mold:-). In general, people do not have a picture of the cast, deeply lodged opinion that from plaster mold ... Time setting plaster solution for 5-10 minutes. A phase when the solution is a little reminiscent of the clay, and is suitable for molding itself lasts less than a minute. Well, what for a period of time you can manage? Therefore, open a lot of terrible secret that all gypsum products is poured into special molds. They can be made of various materials, and also gypsum. We use a special form of silicone. They are reusable. Silicon form looks like. How are the forms, it is a topic for another master class, if you're interested I'll write about that later. It is interesting that when you look at a concave shape, you see a convex image. Why is it no one knows. Can anyone tell me in the comments?

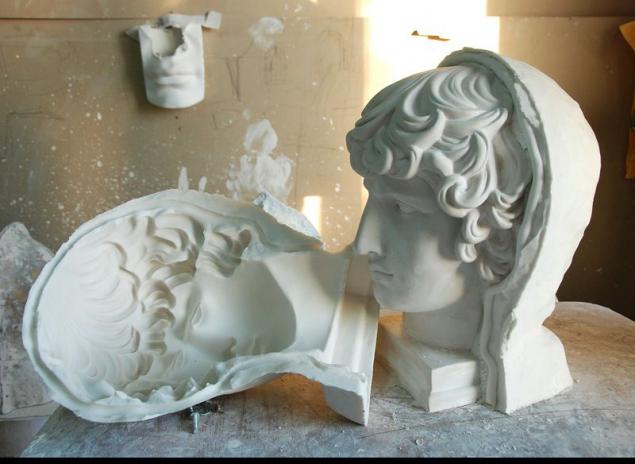

But in the housing halves of the mold. In the background for other forms of heads.

Creating a plaster head begins with a plaster solution. Recipe ingeniously simple: plaster and water. Fill water in the container (in this case a plastic bottle, or rather its lower part).

Pour a scoop of plaster to form a small gorochki above the water surface.

Carefully stir until completely dissolved lumps.

Fill this mixture into the pre-assembled form.

Carefully twist the form to plaster evenly distributed, the donkey on the walls form an even layer.

Repeat this process at least two times completely to avoid thin walls. And you can after the first fill, dissolve plaster and pour a little more until all the forms if you want whole head. But we do hollow. Checklist look inside.

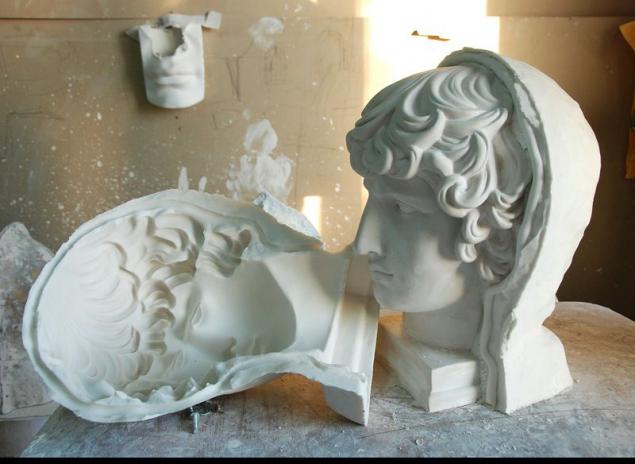

Inside the form gypsum grasped practically forever, finding the shape of the head of the ancient hero. Alter, change something anymore. We are waiting for at least 20 minutes. Take out better when casting hot. Yes, yes, in the process of setting gypsum is heated to 60-70 degrees Celsius. All. It's time to see what we've got. The first thing unscrew the mounting bolts.

Then gently dissociate halves of the mold.

Here is the silicone mold in housing.

Remove the first one half form, then the other.

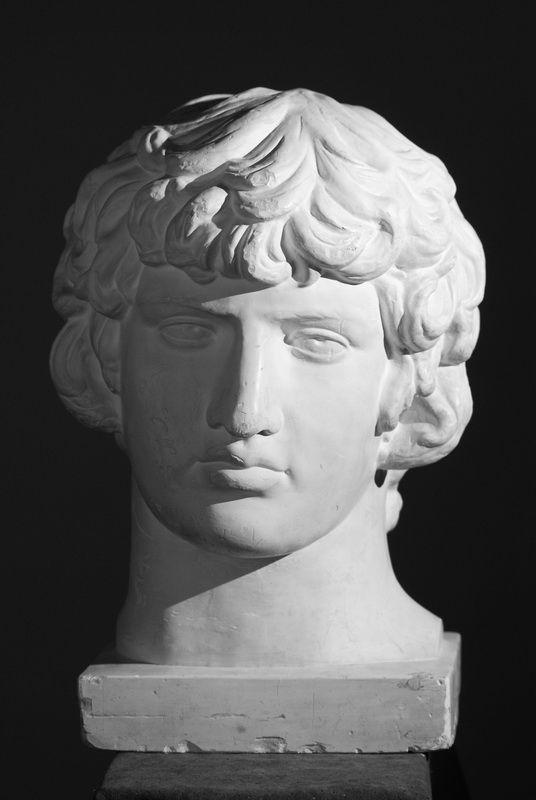

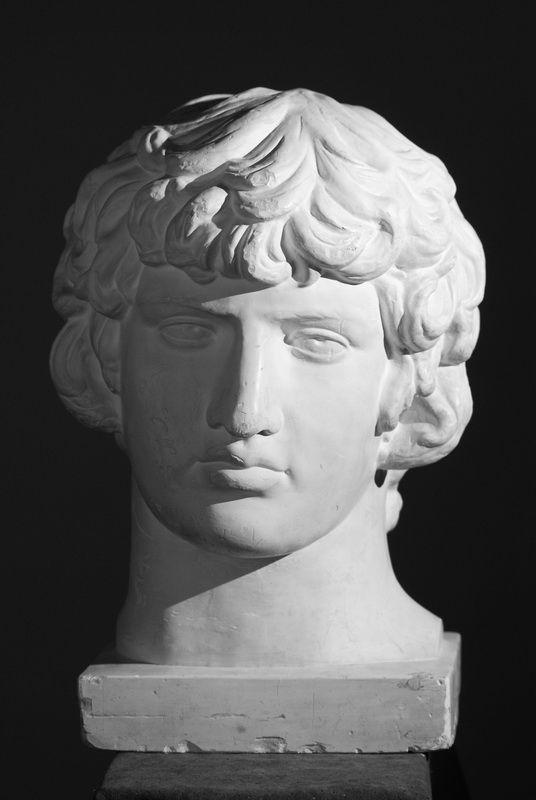

And here it is - the handsome Antinous!

And this is another version of the portrait of Antinous.

But to get the casting - that's not all. It is also necessary to bring to mind, remove burrs and polish the junction of form.

Here's a close-up seam.

Well - we take a knife and forth!

In a little more difficult hair.

We send our Antinous in the dryer! In the company of other Antinous, Aphrodite and Apollo.

Here he will spend a few days. Gypsum because only grasped quickly, dries and surprisingly long, depending on the value of the product and the thickness of its walls, as well as ambient temperature and humidity. When it dries, lose up to half of the weight of the green body, and becomes pure white. Only in such a state, a final sanding the seam.

Gypsum - a wonderful material that has found application in various industries - construction, archeology, medicine, well, in the fine arts course. For example, if someone does not know, fine Pushkin Museum, Tsvetaeva, created as a museum of casts. And in fact, almost all copies of ancient statues collected in it and looking like bronze or marble - a plaster cast taken on a specific technology and life-size bronze tinted or marble, for example, all that is in the courtyard of the Greek, the Roman Hall, Greek, black column of Trajan, a huge portal of the cathedral in Freiberg, tombstones, equestrian statues of condottieri (those that chased hero Nikulin in the film "Old men-robbers"), but the same Michelangelo's David in one of the main halls of the Pushkin Museum. < br />

Source: master-klass.livejournal.com

Many people think that they are made from plaster mold:-). In general, people do not have a picture of the cast, deeply lodged opinion that from plaster mold ... Time setting plaster solution for 5-10 minutes. A phase when the solution is a little reminiscent of the clay, and is suitable for molding itself lasts less than a minute. Well, what for a period of time you can manage? Therefore, open a lot of terrible secret that all gypsum products is poured into special molds. They can be made of various materials, and also gypsum. We use a special form of silicone. They are reusable. Silicon form looks like. How are the forms, it is a topic for another master class, if you're interested I'll write about that later. It is interesting that when you look at a concave shape, you see a convex image. Why is it no one knows. Can anyone tell me in the comments?

But in the housing halves of the mold. In the background for other forms of heads.

Creating a plaster head begins with a plaster solution. Recipe ingeniously simple: plaster and water. Fill water in the container (in this case a plastic bottle, or rather its lower part).

Pour a scoop of plaster to form a small gorochki above the water surface.

Carefully stir until completely dissolved lumps.

Fill this mixture into the pre-assembled form.

Carefully twist the form to plaster evenly distributed, the donkey on the walls form an even layer.

Repeat this process at least two times completely to avoid thin walls. And you can after the first fill, dissolve plaster and pour a little more until all the forms if you want whole head. But we do hollow. Checklist look inside.

Inside the form gypsum grasped practically forever, finding the shape of the head of the ancient hero. Alter, change something anymore. We are waiting for at least 20 minutes. Take out better when casting hot. Yes, yes, in the process of setting gypsum is heated to 60-70 degrees Celsius. All. It's time to see what we've got. The first thing unscrew the mounting bolts.

Then gently dissociate halves of the mold.

Here is the silicone mold in housing.

Remove the first one half form, then the other.

And here it is - the handsome Antinous!

And this is another version of the portrait of Antinous.

But to get the casting - that's not all. It is also necessary to bring to mind, remove burrs and polish the junction of form.

Here's a close-up seam.

Well - we take a knife and forth!

In a little more difficult hair.

We send our Antinous in the dryer! In the company of other Antinous, Aphrodite and Apollo.

Here he will spend a few days. Gypsum because only grasped quickly, dries and surprisingly long, depending on the value of the product and the thickness of its walls, as well as ambient temperature and humidity. When it dries, lose up to half of the weight of the green body, and becomes pure white. Only in such a state, a final sanding the seam.

Gypsum - a wonderful material that has found application in various industries - construction, archeology, medicine, well, in the fine arts course. For example, if someone does not know, fine Pushkin Museum, Tsvetaeva, created as a museum of casts. And in fact, almost all copies of ancient statues collected in it and looking like bronze or marble - a plaster cast taken on a specific technology and life-size bronze tinted or marble, for example, all that is in the courtyard of the Greek, the Roman Hall, Greek, black column of Trajan, a huge portal of the cathedral in Freiberg, tombstones, equestrian statues of condottieri (those that chased hero Nikulin in the film "Old men-robbers"), but the same Michelangelo's David in one of the main halls of the Pushkin Museum. < br />

Source: master-klass.livejournal.com