124

Galvanized masonry netting

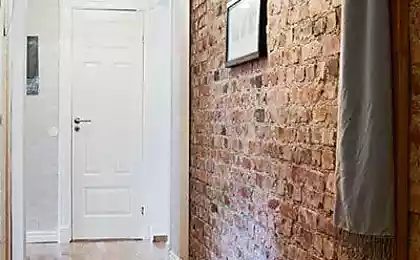

Brick walls have an impressive mass and exert significant pressure on the foundation and soil under them, so the latter are subject to increased requirements for mechanical strength. The bricks themselves and dried cement mortar very well resist working on compression loads, as evidenced by the absence of a significant difference between the upper and lower rows of high-rise buildings. Much more dangerous for them deformation to bending or stretching, in the occurrence of which, even in small values, vertical cracks appear in the walls and the building goes into a dangerous emergency condition for further operation. Most often, this phenomenon indicates mistakes made by geological exploration organizations, architects or builders, but sometimes its cause may be objective reasons, the risk of which should be taken into account at the design stage of the future structure. If there is even the slightest chance of stretching or bending forces, for example in areas with potential seismic activity or adverse soil characteristics, it is better to take measures in advance to prevent their destructive effects. Since neither brick nor cement mortar is able to effectively resist rupture and impact, it is advisable to introduce reinforcing elements into the masonry through one or more rows. The starting material for their production can be, for example, a specially produced masonry galvanized mesh or other types of ferrous metal suitable for this purpose. Which of them to choose depends on the conditions of a specific task, so the final decision and responsibility for it entirely belongs to the specialist conducting calculations on the permissible strength of the design.

Welded galvanized mesh for foundations and reinforced concrete products

The strength of the foundation and various horizontal jumpers over the through openings in the walls is even more important than the masonry. As is well known, before pouring concrete into the formwork, a reinforcing frame of metal is placed. In its composition, there is often a welded galvanized mesh that performs several useful functions. Here are some of them:

- avoiding cracking when tensile forces occur;

- preventing the cracking of near-surface layers of cement solution;

- reliable fixation in a given position of individual elements of the frame structure.

The appearance of loose rust on the surface of rolled steel leads to the cessation of adhesion of reinforcing parts with concrete, which contributes to its gradual destruction. Welded galvanized mesh due to a specially created of iron and zinc galvanic element is protected from corrosion for many decades, because detachment of adhering cement does not occur. The range is sufficient to choose the optimal size for any task.

11 Signs You and Your Girlfriend Are Completely Incompatible

5 Situations When Your Feelings Depreciate