449

Make a brick "coat" for metal stoves

Metal stove, known since the beginning of the last century under the name of "stove" has kept its relevance in our days. Unlike the heater, a metal stove is easier to install, it quickly warmed up, it is convenient to heat small rooms — garages, baths, outbuildings.

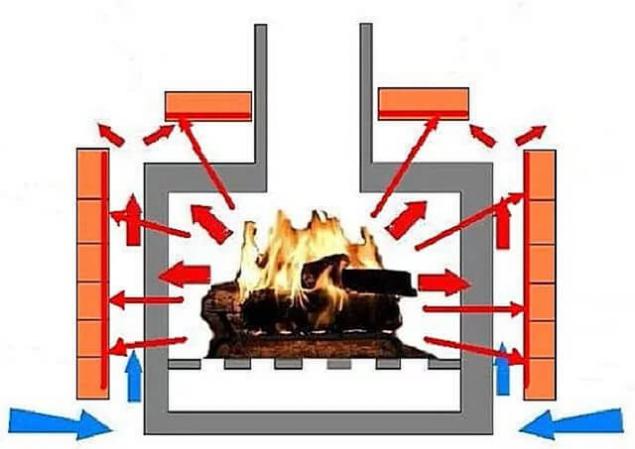

But such a furnace has one very major drawback. Yes, the metal furnace body is heated rapidly. But it also cools down quickly after you stop the flow of fuel. This means that if you need to keep the room warm, for example, all night, you have to assign the duty. The same applies to the installation of the furnace in the bath — the air in the steam room a long time did not cool off, you need to continue to throw in a wood stove.

A way out of this situation — to impose our metal furnace with a brick. This solution has several advantages:

Slow cooling brick casing enables long to keep a room warm without additional heating of the furnace. The brick shell is more secure than red-hot metal casing. To serious burns by touching the hot brick, is almost impossible. The heat from the brick surface more strong and soft, he creates a special microclimate comfortable for humans.

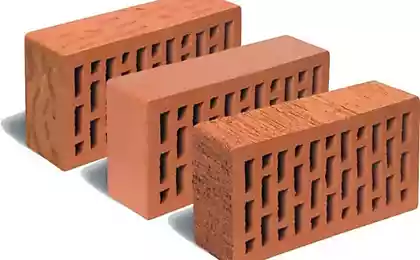

What brick to use, Preference should be given special refractory brick, called firebrick. Only he is able to withstand high temperatures for long periods of time without damage. Fire bricks come in two types, hollow and solid. The use of hollow brick is recommended, if not too to increase the weight of the structure. Shell solid bricks heats up a little longer, but it cools slower.

If you want to give your stove is not only additional functionality but also the aesthetic appearance, you can use a special brick with a textured surface. However, the price it a bit higher than usual.

Preparatory workmasonry will have a very substantial weight, so before starting work you must make calculations to decide whether to strengthen the floor under construction. To do this, the number of rows multiplied by the number of bricks in one row. The resulting figure is multiplied by the weight of one brick — it will be a lot of our design. Her priiplyusovali the weight of the stove and water tank, if available.

With a total weight of over 700 kg, it is recommended to install the oven on a separate Foundation. Not too durable floors can be strengthened by means of supports installed under the joists in the places where will be located the furnace. If the floor is wood, it is necessary to close the metal screen to prevent fire. Sheet fasten the screws or nail so that it completely covers the place of masonry. On the sheet it is advisable to attach a sheet of asbestos cardboard with thickness not less than 4 mm.

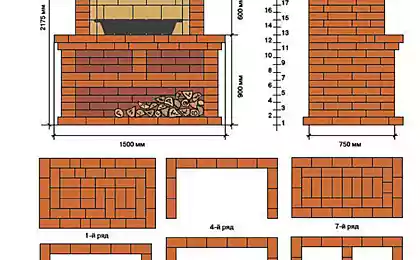

Brick layingMortar, you can buy premixed or make your own from sand, clay or cement. The brick casing should not touch the metal walls of the oven leave a gap of 5-10 mm, to avoid overheating. Masonry wall runs in a half-brick, that is enough to ensure good heating and saves mortar and the building material.

Begin to lay the bricks from the corner. The bricks are laid in a row on the base in length. The ranks are bound together by a layer of mortar, each subsequent row in this case is shifted relative to the previous one by a half-brick. This provides structural strength, as it allows to match the joints of the bricks. The thickness of the resulting wall with standard brick sizes is 120 mm.

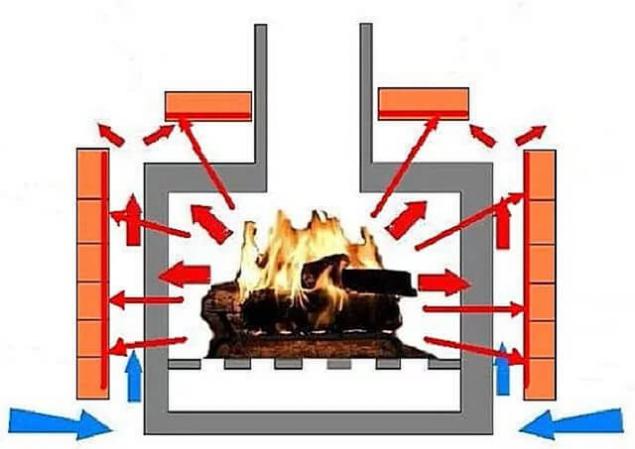

The first row is solid, without holes. In the second row, you must leave the vents of a width not exceeding 5 cm Series with the outputs need to be duplicated several times, the number of such rows depends on the size of the stove. Ventilation is necessary in order that the heat does not remain inside the enclosure, and went outside and warmed the room.

To stack the rows required with the use of the level, avoiding deviations in both the vertical and horizontal. For correction you can use the solution by adding or removing it as necessary. Excess solution should be immediately removed.

In the place where is located the door, lay out the wall so that it does not interfere with the necessary manipulations for opening and closing. The upper edge of the door opening, you can strengthen the metal area.

Sometimes a furnace surrounded by bricks not completely, leaving the top free and filling it with special stones. This technique is characteristic of the bath furnace.

After completion of the work the stove should be left alone for a few days to let the walls dry completely. After two or three days is recommended to conduct a trial heating, not rascala oven to maximum temperature. This will help to speed up the process of drying. Then if you want you can decorate the walls with colored grout, polishing or tiles.published

P. S. And remember, only by changing their consumption — together we change the world! ©

Source: estp-blog.ru/rubrics/rid-42951/

But such a furnace has one very major drawback. Yes, the metal furnace body is heated rapidly. But it also cools down quickly after you stop the flow of fuel. This means that if you need to keep the room warm, for example, all night, you have to assign the duty. The same applies to the installation of the furnace in the bath — the air in the steam room a long time did not cool off, you need to continue to throw in a wood stove.

A way out of this situation — to impose our metal furnace with a brick. This solution has several advantages:

Slow cooling brick casing enables long to keep a room warm without additional heating of the furnace. The brick shell is more secure than red-hot metal casing. To serious burns by touching the hot brick, is almost impossible. The heat from the brick surface more strong and soft, he creates a special microclimate comfortable for humans.

What brick to use, Preference should be given special refractory brick, called firebrick. Only he is able to withstand high temperatures for long periods of time without damage. Fire bricks come in two types, hollow and solid. The use of hollow brick is recommended, if not too to increase the weight of the structure. Shell solid bricks heats up a little longer, but it cools slower.

If you want to give your stove is not only additional functionality but also the aesthetic appearance, you can use a special brick with a textured surface. However, the price it a bit higher than usual.

Preparatory workmasonry will have a very substantial weight, so before starting work you must make calculations to decide whether to strengthen the floor under construction. To do this, the number of rows multiplied by the number of bricks in one row. The resulting figure is multiplied by the weight of one brick — it will be a lot of our design. Her priiplyusovali the weight of the stove and water tank, if available.

With a total weight of over 700 kg, it is recommended to install the oven on a separate Foundation. Not too durable floors can be strengthened by means of supports installed under the joists in the places where will be located the furnace. If the floor is wood, it is necessary to close the metal screen to prevent fire. Sheet fasten the screws or nail so that it completely covers the place of masonry. On the sheet it is advisable to attach a sheet of asbestos cardboard with thickness not less than 4 mm.

Brick layingMortar, you can buy premixed or make your own from sand, clay or cement. The brick casing should not touch the metal walls of the oven leave a gap of 5-10 mm, to avoid overheating. Masonry wall runs in a half-brick, that is enough to ensure good heating and saves mortar and the building material.

Begin to lay the bricks from the corner. The bricks are laid in a row on the base in length. The ranks are bound together by a layer of mortar, each subsequent row in this case is shifted relative to the previous one by a half-brick. This provides structural strength, as it allows to match the joints of the bricks. The thickness of the resulting wall with standard brick sizes is 120 mm.

The first row is solid, without holes. In the second row, you must leave the vents of a width not exceeding 5 cm Series with the outputs need to be duplicated several times, the number of such rows depends on the size of the stove. Ventilation is necessary in order that the heat does not remain inside the enclosure, and went outside and warmed the room.

To stack the rows required with the use of the level, avoiding deviations in both the vertical and horizontal. For correction you can use the solution by adding or removing it as necessary. Excess solution should be immediately removed.

In the place where is located the door, lay out the wall so that it does not interfere with the necessary manipulations for opening and closing. The upper edge of the door opening, you can strengthen the metal area.

Sometimes a furnace surrounded by bricks not completely, leaving the top free and filling it with special stones. This technique is characteristic of the bath furnace.

After completion of the work the stove should be left alone for a few days to let the walls dry completely. After two or three days is recommended to conduct a trial heating, not rascala oven to maximum temperature. This will help to speed up the process of drying. Then if you want you can decorate the walls with colored grout, polishing or tiles.published

P. S. And remember, only by changing their consumption — together we change the world! ©

Source: estp-blog.ru/rubrics/rid-42951/