144

Why I gave up cellular polycarbonate

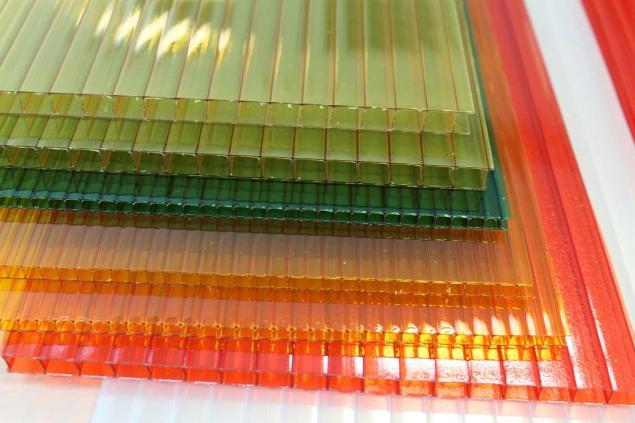

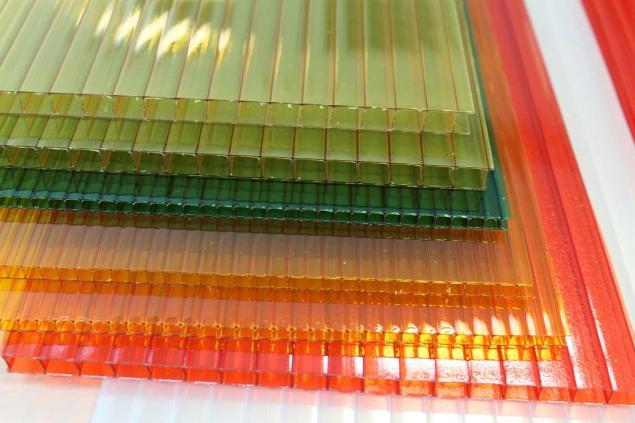

Inexpensive, light, flexible, does not require special care and at the same time allows sunlight. All these qualities made cellular polycarbonate a construction hit of the 2000s. It is worth searching in any yard, and you will find something from this material. If not a greenhouse, then a canopy, fence or visor. However, few people know about his more reliable relative. Sheets of monolithic polycarbonate have their advantages and disadvantages, which we will try to understand.

In 1953, the American company General Electric patented polycarbonate under the brand name "Lexan". It was supposed to be a more modern replacement for glass. But the high price prevented the spread of monolithic polycarbonate on the market.

Twenty years have passed and the transparent material has been rediscovered. This was done by chemists of the Israeli company Polygal. In search of an alternative to fragile glass for greenhouses, they experimented with polycarbonate. At some point, several of its layers were connected by partitions into a cellular structure.

The air-filled honeycombs made the experimental material lighter, increased insulation and noise protection. So the cellular polycarbonate was born. The novelty quickly surpassed in popularity its monolithic brother. And her triumphant march through construction sites around the world does not stop today.

Advantages of cellular polycarbonate

Benefits of Monolithic Polycarbonate

What to choose? Whatever the quality of cellular polycarbonate, in Russia it has to be changed in 5-6 years. It creaks in the wind, deforms and cracks in the heat and frost. In addition, if you do not isolate the ends, it constantly accumulates dirt, dust and moisture.

View this post on Instagram

Posted by NAVESA | TERASSA | TOLIATTI (@navess_na_zakaz)

Monolithic polycarbonate is more expensive and almost five times heavier. But it is much stronger, better bends and lets in sunlight. And its service life is up to 25 years.

View this post on Instagram

Publication from METALLOPRODUCTION | SERBOURS (@bulatt.market)

As you can see, each material has its own strengths and weaknesses. What to choose in each case is up to you. But the main thing to remember is that the popular cellular polycarbonate has a durable, aesthetic and durable alternative.

In 1953, the American company General Electric patented polycarbonate under the brand name "Lexan". It was supposed to be a more modern replacement for glass. But the high price prevented the spread of monolithic polycarbonate on the market.

Twenty years have passed and the transparent material has been rediscovered. This was done by chemists of the Israeli company Polygal. In search of an alternative to fragile glass for greenhouses, they experimented with polycarbonate. At some point, several of its layers were connected by partitions into a cellular structure.

The air-filled honeycombs made the experimental material lighter, increased insulation and noise protection. So the cellular polycarbonate was born. The novelty quickly surpassed in popularity its monolithic brother. And her triumphant march through construction sites around the world does not stop today.

Advantages of cellular polycarbonate

- Low price. It makes cellular plates available to the vast majority of buyers.

- Since most of the material is air, it is very different. low-weight. The ease of such sheets facilitates installation, simplifies and cheapens the construction of buildings. For example, in the construction of greenhouses they do not require too strong frame.

- Air-filled cells do not respond well to external heating or cooling. Thus, low thermal conductivity Cellular polycarbonate helps maintain heat.

Benefits of Monolithic Polycarbonate

- Monolithic polycarbonate stronger Cellular and 250 times stronger than glass. And the sheet, which is 4 mm thick, simply cannot be broken with a hammer.

View this post on Instagram

Publication from NAVESA | TORN | GATE (@grand_naves)

It copes well with shock loads and is resistant to constants. Therefore, it is better for arranging canopies where a lot of snow falls. And greenhouses from it serve for a long time even in places with strong winds. - Due to the absence of partitions, monolithic polycarbonate much more transparent Cellular.

View this post on Instagram

Publication from Greenhouse, polycarbonate Chekhov (@plastservic_chekhov)

You can see through it quite clearly, almost like through glass. - Resistance to the environment. You may have noticed how cellular polycarbonate cracks even when heated by sunlight. Monolithic polycarbonate, on the contrary, retains characteristics at 40 degrees of frost and 135 (!) heat. And briefly withstands heating to 160 degrees.

What to choose? Whatever the quality of cellular polycarbonate, in Russia it has to be changed in 5-6 years. It creaks in the wind, deforms and cracks in the heat and frost. In addition, if you do not isolate the ends, it constantly accumulates dirt, dust and moisture.

View this post on Instagram

Posted by NAVESA | TERASSA | TOLIATTI (@navess_na_zakaz)

Monolithic polycarbonate is more expensive and almost five times heavier. But it is much stronger, better bends and lets in sunlight. And its service life is up to 25 years.

View this post on Instagram

Publication from METALLOPRODUCTION | SERBOURS (@bulatt.market)

As you can see, each material has its own strengths and weaknesses. What to choose in each case is up to you. But the main thing to remember is that the popular cellular polycarbonate has a durable, aesthetic and durable alternative.

The house will smell good even from the sink.

How to save your son’s family from the revenge of a pregnant mistress