451

About original Russian supercapacitors and the first device with their application

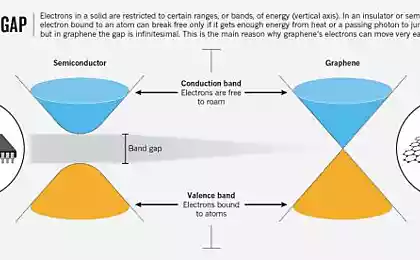

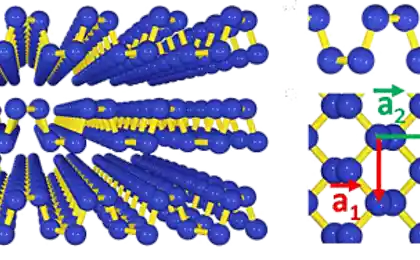

Recently had sostenibilitat Misa in cooperation with the company TEAM unique material, competitive graphene and nanotubes (in this case it is many times they are cheaper). Using new material, in Russia, have developed supercapacitors, which are in turn used in the systems for starting the engines of heavy equipment at extremely low temperatures.

Inside the supercapacitor — nanocarbon material made of organic fiber with high conductivity and high energy density – up to 20 f/CC of active mass (one of the most common in the scientific community of his names — "Vickery") and low production costs. The new ideology of the Assembly of the modules of supercapacitors, reducing the complexity of manufacturing of disk drives, and the original technology for producing electrode materials of organic fibres in the future, reduce the manufacturing cost of the battery almost 3 times, say representatives of the company "TEEMP". Production of the new Russian supercapacitors as previously described is scheduled to launch in the first quarter of 2017 in Khimki (Moscow region).

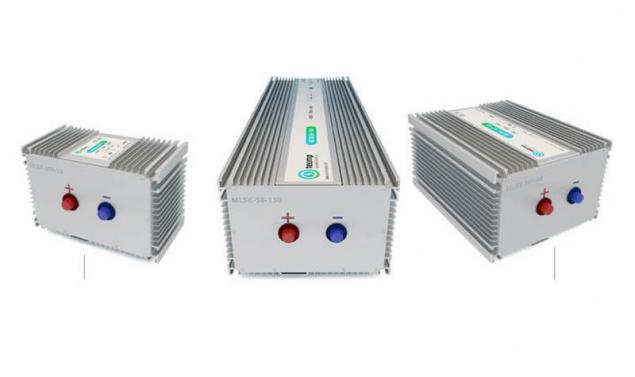

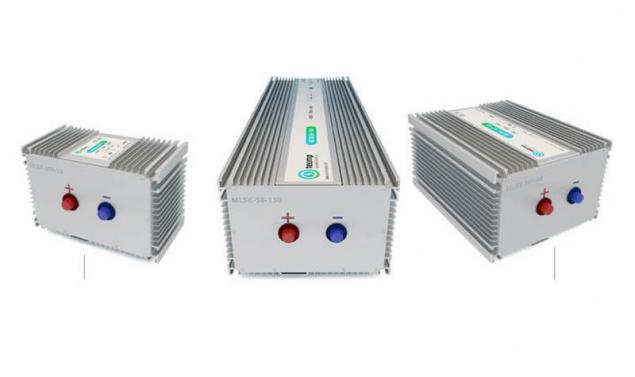

The first line of devices using supercapacitors, a new type is created (photo at the end of the material). The focus in the attention on the system start-up, "containing within a hybrid electric energy storage device based on the module of supercapacitors and gasoline generator". It can work offline, does not require mains power and charged maybe 10 times in a row to get, for example, heavy dump truck at temperatures from -40 °C to -60° C. the System can be used to launch small aircraft that require high power in a short period of time, which quickly displays the usual battery failure. This device has been tested in the fall of 2016 to launch military equipment and received positive feedback. published

P. S. And remember, only by changing their consumption — together we change the world! ©

Source: oko-planet.su/science/sciencenews/355179-pro-originalnye-rossiyskie-superkondensatory-i-pervye-ustroystva-s-ih-primeneniem.html

Inside the supercapacitor — nanocarbon material made of organic fiber with high conductivity and high energy density – up to 20 f/CC of active mass (one of the most common in the scientific community of his names — "Vickery") and low production costs. The new ideology of the Assembly of the modules of supercapacitors, reducing the complexity of manufacturing of disk drives, and the original technology for producing electrode materials of organic fibres in the future, reduce the manufacturing cost of the battery almost 3 times, say representatives of the company "TEEMP". Production of the new Russian supercapacitors as previously described is scheduled to launch in the first quarter of 2017 in Khimki (Moscow region).

The first line of devices using supercapacitors, a new type is created (photo at the end of the material). The focus in the attention on the system start-up, "containing within a hybrid electric energy storage device based on the module of supercapacitors and gasoline generator". It can work offline, does not require mains power and charged maybe 10 times in a row to get, for example, heavy dump truck at temperatures from -40 °C to -60° C. the System can be used to launch small aircraft that require high power in a short period of time, which quickly displays the usual battery failure. This device has been tested in the fall of 2016 to launch military equipment and received positive feedback. published

P. S. And remember, only by changing their consumption — together we change the world! ©

Source: oko-planet.su/science/sciencenews/355179-pro-originalnye-rossiyskie-superkondensatory-i-pervye-ustroystva-s-ih-primeneniem.html

Belgian company ECAR BELGIAN showed its electric tricycle at the Brussels Motor Show

In Tokyo introduced the Prius for an active holiday