476

New save system summer heat and use it in the winter

Avoiding the use of fossil fuels for heating is a necessary component to preserve the environment, but this is very difficult to achieve when a lot of people with one turning up the thermostat on a gas or electric heater you get instant and uninterrupted heat.

People need to be convinced that the transition to renewable energy sources, it's easy and affordable to operate such systems. A group of Swiss researchers argues that the invented process that retains the heat captured during the summer for easy use of the type "on/off" in the winter, with the added benefit of received energy can be physically transported to the desired location as needed.

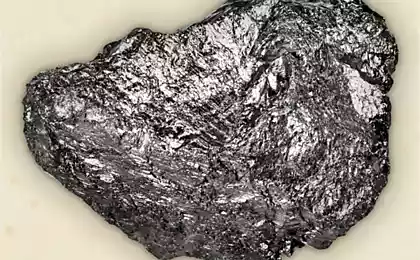

Created by researchers in EMPA (Eidgenössische Materialprüfungs-und Forschungs Anstalt, which means the Swiss Federal laboratory testing and research materials), the new system uses a concentrated sodium hydroxide (NaOH) as a medium of heat storage, and a large number of components to capture, transform and use at the right time of heat.

To achieve their goal, researchers rely on the fact that when water is poured on dry sodium hydroxide is exothermic reaction in which the chemical energy contained in NaOH is released as heat. NaOH is extremely hygroscopic (i.e., it has the ability to drag and hold water molecules from the environment), a greater amount of heat is produced from water condensing out of the air that heats the sodium hydroxide solution even more. Thus, a large amount of heat can be released simply by adding water to NaOH.

Conversely, if the thermal energy (e.g. received from the sun), served in a sodium hydroxide solution, diluted with water, moisture evaporates easily, and the NaOH solution becomes more concentrated and, therefore, effectively saves the energy. This concentrated mixture can be stored for many months (or years), until not need to re-heat, for which, again, NaOH is exposed to water. This energy also can be easily transported in tanks to the place where the required heat energy.

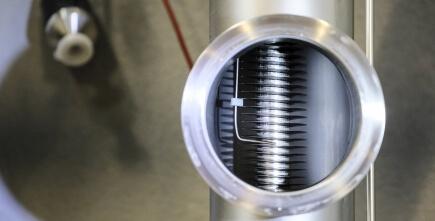

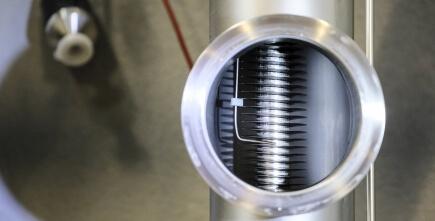

In practice, the energy source is a viscous liquid and consists of a 50% NaOH solution, which flows through the spiral pipe (heat exchangers sostavlyayuschie obychnaya water heaters), where polomalsya water vapor and then passed the emitted heat in the pipe. Then heat is transferred by radiation, convection and conduction in a needed area.

During this process, the sodium hydroxide solution is sent out from the spiral heat exchanger, where it is diluted to a 30% solution in proobrazom condition, and the water temperature in the pipe rises to approximately 50 ° C (122 ° F). That, by happy coincidence, makes this coolant perfect for Underfloor heating.

Although the technology is still in the prototype stage, EMPA is currently seeking commercial partners that would help in creating a compact version of the system for everyday home use.published

P. S. And remember, only by changing their consumption — together we change the world! ©

Source: ecotechnology

People need to be convinced that the transition to renewable energy sources, it's easy and affordable to operate such systems. A group of Swiss researchers argues that the invented process that retains the heat captured during the summer for easy use of the type "on/off" in the winter, with the added benefit of received energy can be physically transported to the desired location as needed.

Created by researchers in EMPA (Eidgenössische Materialprüfungs-und Forschungs Anstalt, which means the Swiss Federal laboratory testing and research materials), the new system uses a concentrated sodium hydroxide (NaOH) as a medium of heat storage, and a large number of components to capture, transform and use at the right time of heat.

To achieve their goal, researchers rely on the fact that when water is poured on dry sodium hydroxide is exothermic reaction in which the chemical energy contained in NaOH is released as heat. NaOH is extremely hygroscopic (i.e., it has the ability to drag and hold water molecules from the environment), a greater amount of heat is produced from water condensing out of the air that heats the sodium hydroxide solution even more. Thus, a large amount of heat can be released simply by adding water to NaOH.

Conversely, if the thermal energy (e.g. received from the sun), served in a sodium hydroxide solution, diluted with water, moisture evaporates easily, and the NaOH solution becomes more concentrated and, therefore, effectively saves the energy. This concentrated mixture can be stored for many months (or years), until not need to re-heat, for which, again, NaOH is exposed to water. This energy also can be easily transported in tanks to the place where the required heat energy.

In practice, the energy source is a viscous liquid and consists of a 50% NaOH solution, which flows through the spiral pipe (heat exchangers sostavlyayuschie obychnaya water heaters), where polomalsya water vapor and then passed the emitted heat in the pipe. Then heat is transferred by radiation, convection and conduction in a needed area.

During this process, the sodium hydroxide solution is sent out from the spiral heat exchanger, where it is diluted to a 30% solution in proobrazom condition, and the water temperature in the pipe rises to approximately 50 ° C (122 ° F). That, by happy coincidence, makes this coolant perfect for Underfloor heating.

Although the technology is still in the prototype stage, EMPA is currently seeking commercial partners that would help in creating a compact version of the system for everyday home use.published

P. S. And remember, only by changing their consumption — together we change the world! ©

Source: ecotechnology

The hemp house. The use of fires in construction

New save system summer heat and use it in the winter