1180

How to make a heat pump Frenette their hands

The name Eugene Frenette well known not only in the scientific world, but also among the home handyman and Amateur inventors. This scientist invented, and then perfected a device which is capable with high efficiency to heat residential and industrial premises. Guided by his ideas, many craftsmen could manufacture heat pump Frenette their hands, and even effectively to improve it.

The principle of operation of the device

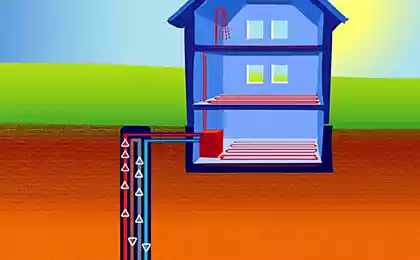

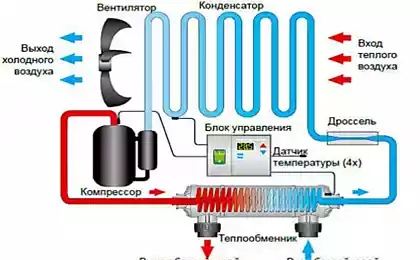

Those who are in contact with the issues of cost-effective heating, the name “heat pump” is very familiar. Especially in combination with terms like “earth-water”, “water-water”, “water-air”, etc. This heat pump device Frenette has almost nothing in common, except that the name and final result in the form of thermal energy which is used for heating.

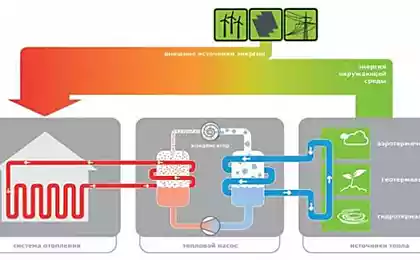

Heat pumps operating on the principle of Carnot, very popular as cost-effective ways of heating, and as an ecologically safe system. The operation of such complex devices has been the accumulation of low-grade energy contained in natural resources (land, water, air), and convert it into heat energy with high potential. The invention Eugenia Frenette works quite differently.

For the manufacture of heat pump Frenette'll need the engine, radiator, some hoses, steel disc, steel discs, metal or plastic rod, a metal cylinder and spanner set (+)

The principle of this device is based on the use of thermal energy released during the friction. Based on the design — metallic surface located close to each other, and at some distance. The space between them filled with liquid. Of the device rotate relative to each other with the electric motor, the fluid contained within the housing and in contact with rotating elements, warming up.

The resulting heat can be used for heating the coolant. Some sources recommend the use of the liquid directly to the heating system. Most often, a self-made pump Frenette attached to an ordinary radiator. The liquid for heating experts strongly recommend to use oil, not water.

In the process of pump operation this coolant tends to warm up very much. The water in these conditions may just boil. The hot steam in a confined space creates excess pressure, and this usually leads to rupture of the pipe or casing. To use oil in such a situation is much safer, because its boiling point is much higher.

There is a perception that efficiency of the heat source exceeds 100% and can even reach 1000%. From the point of view of physics and mathematics is not entirely correct statement. Efficiency reflects the loss of energy that is spent not on heating, and the actual operation of the device. Rather phenomenal statements about the incredibly high efficiency pump Frenette reflect his effectiveness, which is really impressive.

The cost of electricity for the operation of the device is negligible, but the amount of resulting heat is very noticeable. Heating the coolant to the same temperature by a heating element, for example, would require significantly more electricity, possibly ten times more. Household heater at this flow of electricity is not even warmed up.

Why are such devices not equipped with everything residential and industrial premises? The reasons may be different. Still water is more simple and convenient coolant than oil. It is not heated to such high temperatures, and to eliminate the effects of water leaks is easier to remove than the spilled oil.

Another reason may be that by the time of the invention of the pump Frenette centralized heating system already existed and functioned successfully. Dismantling for replacement of the generators would cost too much and would have caused a lot of inconvenience, so this option no one seriously had not even considered. As they say, the best is the enemy of the good.

Recommendations for the use of the device

It should be noted that variations of the pump Eugene Frenette using water as the coolant do exist. But it's usually large industrial models, which are used by specialized companies. The operation of these devices is strictly controlled using special instruments. To provide this level of security at home is almost impossible.

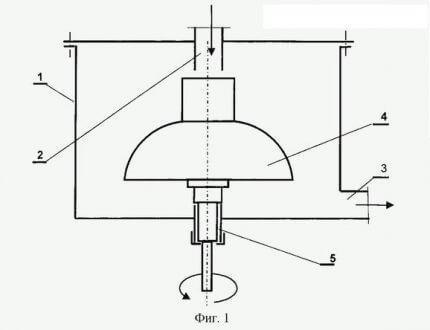

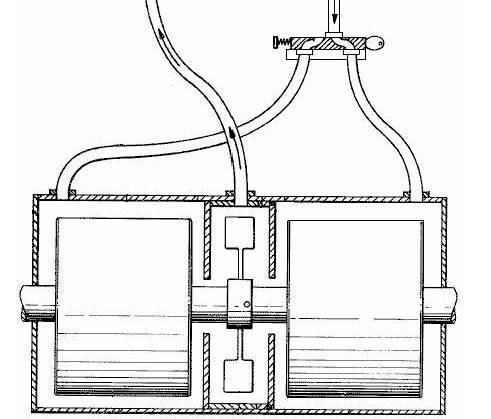

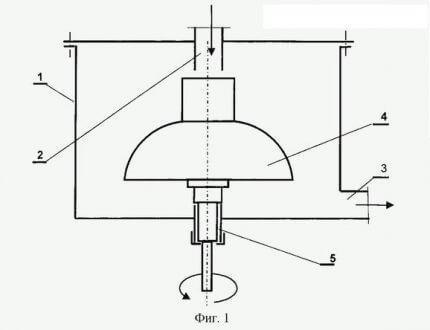

The General scheme of the industrial heat source, developed by scientists in Khabarovsk: 1 — tank; 2 — inlet pipe; 3 — outlet; 4 — heater; 5 — bearing shaft. As the coolant is water

The most popular version of the pump Frenette, where as the coolant is water, not oil, is a device developed by scientists from Khabarovsk: Nazyrova Natalia Ivanovna, Leonov Mikhail Pavlovich and Serg Alexander Vasilyevich. In this mushroom-shaped construction, the water specially brought to the boil and turns to steam.

Then used the reactive power of steam to boost the speed of movement of the liquid coolant through the pump up to 135 meters per minute. As a result the cost of energy for movement of the coolant is minimal and the return in the form of thermal energy is very high. But such a unit must be extremely durable, and its work must be constantly monitored to avoid accidents.

What to do if the pump Frenette it is supposed to organize heating of large room or the whole house? Water, the traditional coolant, most heating systems are designed exactly. Yes, and filling a heating system suitable liquid oil can be expensive.

This issue is solved very simply. Need to build a conventional heat exchanger in which the hot oil will heat the water circulating in the heating system. Some heat will be lost, but the overall effect remains quite noticeable.

Heat pump Frenette can be successfully used in combination with water floor heating systems. But instead of water in the pipe to pour liquid oil

An interesting idea might be to use a pump Frenette in combination with floor heating system. The coolant is thus allowed through narrow plastic pipes laid in a concrete screed. There was a heating system in the same way as a conventional water heat-insulated floor. Of course, this type of project can be realized only in a private home, because a high-rise apartment buildings only use electric floor heating.

Practical and convenient way of applying such a device — heating small rooms: the garage, shed, workshop, etc. Pump Frenette quickly and efficiently solve the problem of Autonomous heating in such places. The cost of electricity for its operation is small compared to the resulting thermal effect, and to construct such a unit is not difficult from the simplest materials.

The design of the pump Frenette

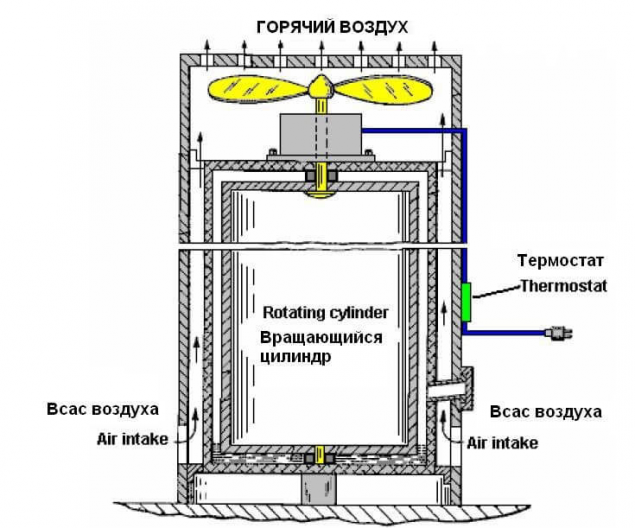

Eugene Frenette not only invented the device that bears his name, but repeatedly it was improved, coming up with new, more efficient versions of the device. In the first pump, which the inventor patented in 1977, was used only two cylinders: inner and outer. A hollow outer cylinder was larger diameter and was in a static condition. The inner cylinder diameter was slightly smaller than the size of the cavity of the outer cylinder.

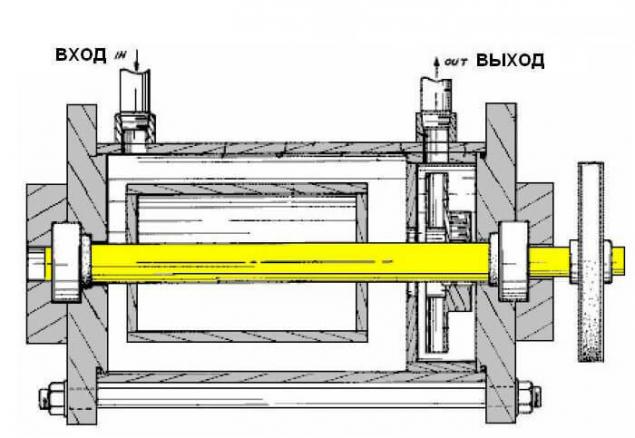

This is a diagram of the first variant of the heat pump Frenette. The rotating shaft is set horizontally, the heat carrier is placed in a narrow space between two working cylinders

The resulting narrow space between the walls of two cylinders, the inventor of the liquid filled oil. Of course, that part of the design, which was this liquid coolant has been carefully sealed to prevent leakage of oil.

The inner cylinder connected to the shaft of the motor so to ensure its rapid rotation relative to the fixed large cylinder. At the opposite end of the structure was placed on the fan impeller. During operation the oil warmed up and transferred heat to the air surrounding the device. The fan could quickly circulate the warm air throughout the room volume.

Since heated this design is quite for convenient and safe use of the structure was hidden in a protective case. Of course, the body was made holes for air circulation. A useful addition to the design was the thermostat, by which the operation of the pump Frenette it was possible to automate to some extent.

The Central axis in this model, the heat pump arranged vertically. The motor is at the bottom, then set nested into each other cylinders, and the top is a fan. Later, a model with a horizontal Central axis.

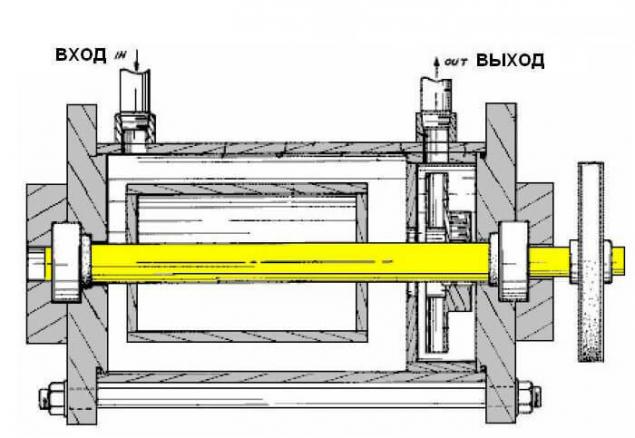

Heat pump model Frenette with a horizontally oriented rotating shaft was used along with a radiator, inside of which circulates the heated oil

Such a device was first used in conjunction not with the fan and radiator. The engine is placed sideways, and the rotor shaft passes through the rotating drum and goes out. In the device of this type, the fan is missing. Coolant from the pump through the pipes is moved to the radiator. Similarly, the heated oil can be withdrawn and another heat exchanger or directly in the heating pipes.

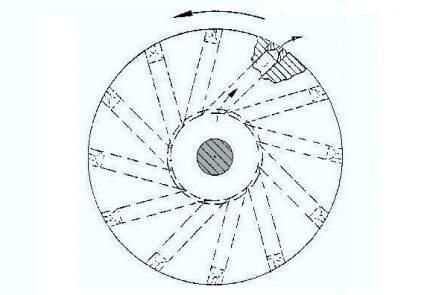

Later, the construction of the heat pump frenette was substantially changed. The rotor shaft remains in a horizontal position, but the inner part was made of two rotating drums and placed between them the impeller. As the coolant is used again here liquid oil.

In this embodiment, the heat pump Frenette two tilera revolve around, they are separated by an impeller of special design, made from very durable metal

During the rotation of this design the oil is further heated as it goes through the holes made in the impeller, and then enters a narrow cavity between the walls of the pump casing and rotor. Thus, the efficiency of the pump Frenette was significantly increased.

The edges of the impeller for the heat pump Frenette made a small hole. The coolant is quickly and effectively heated passing through them

However, it should be noted that for making at home this type of pump is not ideal. To start you will need to find reliable drawings or to calculate the design of their own, and it is only by an experienced engineer. You will then need to find a special impeller with holes of a suitable size. This element of the heat pump is operating at high loads, so it needs to be made of very durable materials.

Independent production device

Overview of the device variants of the pump Frenette allows you to understand that how it works with varying degree of effectiveness can be used in constructions of different type and kind. The basic idea remains the same: the narrow space between the elements of metal, filled with oil, and rotation by an electric motor.

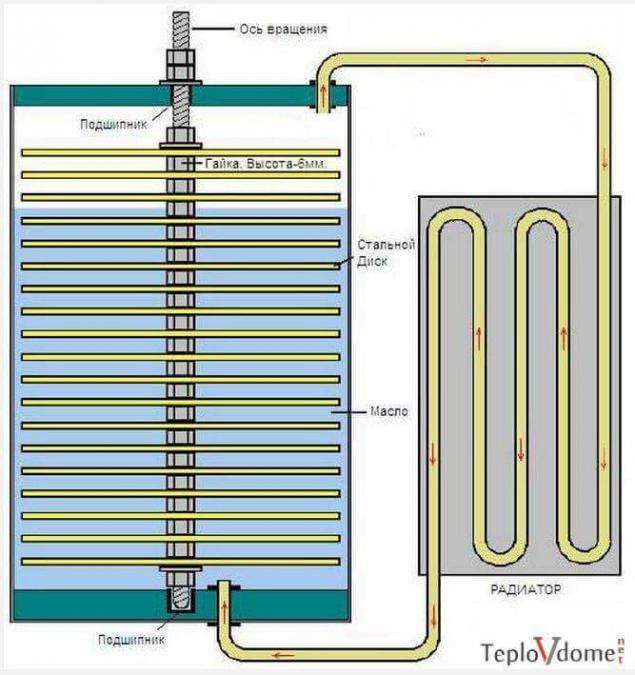

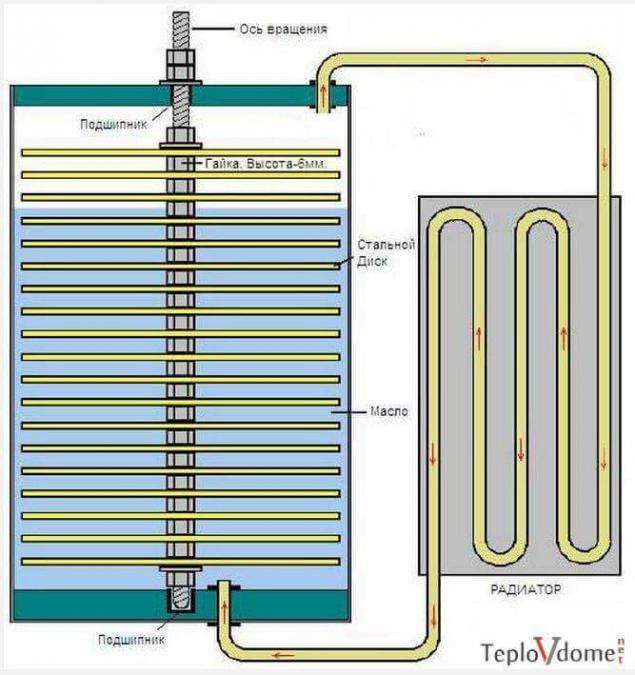

The diagram shows a variant of the heat pump Frenette, which is commonly used for manufacturing the device. The basis of design — metal disks separated nuts (+)

At home, most often made pump Frenette, consisting of a series of metal plates separated by a narrow space. To fabricate such a device, all you need to begin to find and prepare the necessary materials:

It is obvious that the hole in the disk should be such that they can be freely put on the axial rod. The outer diameter of the disc should be less of the case by a few millimeters. If you are willing elements at hand was not, the wheels cut their own sheet metal, or assign this work to Turner.

The cylindrical body can be made from old metal containers suitable configuration or weld metal. And fit a piece of wide metal pipe. To the ends of the cylinder is welded to the wall. The enclosure must be sealed so that the oil does not leak. In the upper and lower end of the body should make additional holes: inlet and outlet heating pipes leading to the radiator.

Of course, all of the joints of the pipes should be sealed. For threaded connections use special seals: FUM-feed, flax, etc. If you decide to use PVC pipe, you will need special fittings and possibly a soldering iron for the installation of these pipes.

For pump operation Frenette high-performance motor is not needed. Suitable device, taken with the old or broken home appliances, for example, with a normal fan. The main purpose for the motor to rotate the shaft. Excessively rapid rotation may cause incorrect operation of the device. The faster the rotation design, the greater the heat the coolant.

Small engine crank shaft of the heat pump Frenette can be removed with broken appliances or to buy at the store

To the rod spun freely, needs a suitable bearing in standard sizes. When all the elements prepared, you can start assembling the device. First, on the lower part inside the housing installing the Central axis with the bearing. Then, on the axis of the separation nut is screwed and put on a disk, nut, disk, etc.

Drives nuts to alternate until the case is filled to the brim. At the stage of preparation it is possible to make preliminary calculations on the number of necessary discs and nuts. Need to the thickness of the nut (6 mm) was added to the thickness of the disk. The height of the housing is divided by this figure. The resulting number will give information about the desired number of pairs of “nut+disc”. The latter set the nut.

After the case is filled with these moving parts, it is filled with liquid oil. The oil type doesn't matter, you can take mineral, cottonseed, rapeseed or any other oil that tolerates heat and does not freeze. After that the design cover with the top cover and gently sealed.

By this time cooler pipes is normally attached to the lids. For convenience during the further installation and maintenance on the pipes you can put two of stopcock. Now on to the motor shaft connecting the axle of the heat pump. System include the network, check for leaks, evaluate the performance of the device.

Made heat pump Frenette can be connected to a conventional cast-iron or bimetal radiator, which will provide the necessary heating effect

If done correctly, the axis with the disks starts to spin, warming up inside the device oil. Hot coolant will move through the upper hole on the tube in the radiator. The cooled oil will return to the case of a heat pump in the down pipe for re-heating.

To automate the system, you can use special relays with a temperature sensor that detects heating of the case of the heat pump and stops the engine or turns it on as needed. This will prevent overheating of the system, the hazards in General will increase the life of the device.

An interesting variant of the pump Frenette presented in this video:

Put LIKES and share with your FRIENDS!

www.youtube.com/channel/UCXd71u0w04qcwk32c8kY2BA/videos

The following video shows a successful experience of start of the heat generator in which water is used:

Put LIKES and share with your FRIENDS!

www.youtube.com/channel/UCXd71u0w04qcwk32c8kY2BA/videos

Unfortunately, the pump Frenette not found wide acceptance in the field of heating. Such a device of industrial production for domestic use is difficult to find in stores equipment for home. But many folk artists have successfully used the achievements of this scientist and applied them in their residences, baths, garages, etc.

P. S. And remember, only by changing their consumption — together we change the world! ©

Source: sovet-ingenera.com/eco-energy/teplovye-nasosy/teplovoj-nasos-frenetta-svoimi-rukami.html

The principle of operation of the device

Those who are in contact with the issues of cost-effective heating, the name “heat pump” is very familiar. Especially in combination with terms like “earth-water”, “water-water”, “water-air”, etc. This heat pump device Frenette has almost nothing in common, except that the name and final result in the form of thermal energy which is used for heating.

Heat pumps operating on the principle of Carnot, very popular as cost-effective ways of heating, and as an ecologically safe system. The operation of such complex devices has been the accumulation of low-grade energy contained in natural resources (land, water, air), and convert it into heat energy with high potential. The invention Eugenia Frenette works quite differently.

For the manufacture of heat pump Frenette'll need the engine, radiator, some hoses, steel disc, steel discs, metal or plastic rod, a metal cylinder and spanner set (+)

The principle of this device is based on the use of thermal energy released during the friction. Based on the design — metallic surface located close to each other, and at some distance. The space between them filled with liquid. Of the device rotate relative to each other with the electric motor, the fluid contained within the housing and in contact with rotating elements, warming up.

The resulting heat can be used for heating the coolant. Some sources recommend the use of the liquid directly to the heating system. Most often, a self-made pump Frenette attached to an ordinary radiator. The liquid for heating experts strongly recommend to use oil, not water.

In the process of pump operation this coolant tends to warm up very much. The water in these conditions may just boil. The hot steam in a confined space creates excess pressure, and this usually leads to rupture of the pipe or casing. To use oil in such a situation is much safer, because its boiling point is much higher.

There is a perception that efficiency of the heat source exceeds 100% and can even reach 1000%. From the point of view of physics and mathematics is not entirely correct statement. Efficiency reflects the loss of energy that is spent not on heating, and the actual operation of the device. Rather phenomenal statements about the incredibly high efficiency pump Frenette reflect his effectiveness, which is really impressive.

The cost of electricity for the operation of the device is negligible, but the amount of resulting heat is very noticeable. Heating the coolant to the same temperature by a heating element, for example, would require significantly more electricity, possibly ten times more. Household heater at this flow of electricity is not even warmed up.

Why are such devices not equipped with everything residential and industrial premises? The reasons may be different. Still water is more simple and convenient coolant than oil. It is not heated to such high temperatures, and to eliminate the effects of water leaks is easier to remove than the spilled oil.

Another reason may be that by the time of the invention of the pump Frenette centralized heating system already existed and functioned successfully. Dismantling for replacement of the generators would cost too much and would have caused a lot of inconvenience, so this option no one seriously had not even considered. As they say, the best is the enemy of the good.

Recommendations for the use of the device

It should be noted that variations of the pump Eugene Frenette using water as the coolant do exist. But it's usually large industrial models, which are used by specialized companies. The operation of these devices is strictly controlled using special instruments. To provide this level of security at home is almost impossible.

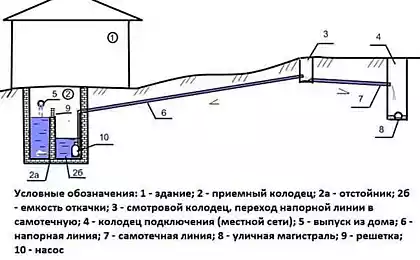

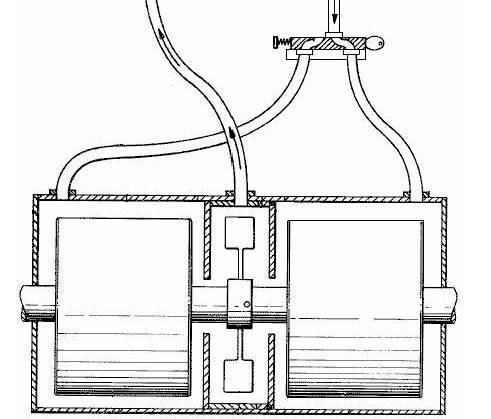

The General scheme of the industrial heat source, developed by scientists in Khabarovsk: 1 — tank; 2 — inlet pipe; 3 — outlet; 4 — heater; 5 — bearing shaft. As the coolant is water

The most popular version of the pump Frenette, where as the coolant is water, not oil, is a device developed by scientists from Khabarovsk: Nazyrova Natalia Ivanovna, Leonov Mikhail Pavlovich and Serg Alexander Vasilyevich. In this mushroom-shaped construction, the water specially brought to the boil and turns to steam.

Then used the reactive power of steam to boost the speed of movement of the liquid coolant through the pump up to 135 meters per minute. As a result the cost of energy for movement of the coolant is minimal and the return in the form of thermal energy is very high. But such a unit must be extremely durable, and its work must be constantly monitored to avoid accidents.

What to do if the pump Frenette it is supposed to organize heating of large room or the whole house? Water, the traditional coolant, most heating systems are designed exactly. Yes, and filling a heating system suitable liquid oil can be expensive.

This issue is solved very simply. Need to build a conventional heat exchanger in which the hot oil will heat the water circulating in the heating system. Some heat will be lost, but the overall effect remains quite noticeable.

Heat pump Frenette can be successfully used in combination with water floor heating systems. But instead of water in the pipe to pour liquid oil

An interesting idea might be to use a pump Frenette in combination with floor heating system. The coolant is thus allowed through narrow plastic pipes laid in a concrete screed. There was a heating system in the same way as a conventional water heat-insulated floor. Of course, this type of project can be realized only in a private home, because a high-rise apartment buildings only use electric floor heating.

Practical and convenient way of applying such a device — heating small rooms: the garage, shed, workshop, etc. Pump Frenette quickly and efficiently solve the problem of Autonomous heating in such places. The cost of electricity for its operation is small compared to the resulting thermal effect, and to construct such a unit is not difficult from the simplest materials.

The design of the pump Frenette

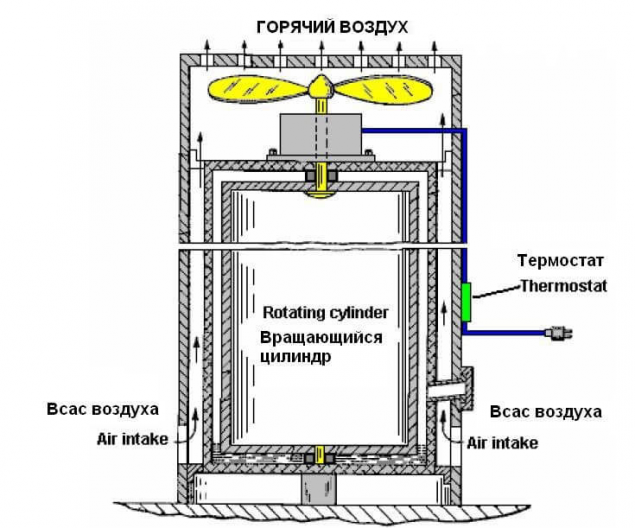

Eugene Frenette not only invented the device that bears his name, but repeatedly it was improved, coming up with new, more efficient versions of the device. In the first pump, which the inventor patented in 1977, was used only two cylinders: inner and outer. A hollow outer cylinder was larger diameter and was in a static condition. The inner cylinder diameter was slightly smaller than the size of the cavity of the outer cylinder.

This is a diagram of the first variant of the heat pump Frenette. The rotating shaft is set horizontally, the heat carrier is placed in a narrow space between two working cylinders

The resulting narrow space between the walls of two cylinders, the inventor of the liquid filled oil. Of course, that part of the design, which was this liquid coolant has been carefully sealed to prevent leakage of oil.

The inner cylinder connected to the shaft of the motor so to ensure its rapid rotation relative to the fixed large cylinder. At the opposite end of the structure was placed on the fan impeller. During operation the oil warmed up and transferred heat to the air surrounding the device. The fan could quickly circulate the warm air throughout the room volume.

Since heated this design is quite for convenient and safe use of the structure was hidden in a protective case. Of course, the body was made holes for air circulation. A useful addition to the design was the thermostat, by which the operation of the pump Frenette it was possible to automate to some extent.

The Central axis in this model, the heat pump arranged vertically. The motor is at the bottom, then set nested into each other cylinders, and the top is a fan. Later, a model with a horizontal Central axis.

Heat pump model Frenette with a horizontally oriented rotating shaft was used along with a radiator, inside of which circulates the heated oil

Such a device was first used in conjunction not with the fan and radiator. The engine is placed sideways, and the rotor shaft passes through the rotating drum and goes out. In the device of this type, the fan is missing. Coolant from the pump through the pipes is moved to the radiator. Similarly, the heated oil can be withdrawn and another heat exchanger or directly in the heating pipes.

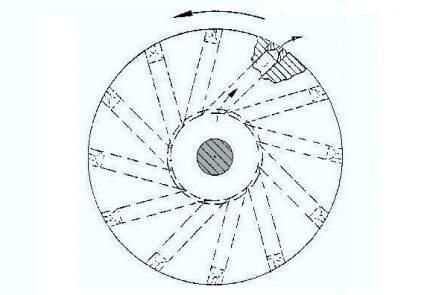

Later, the construction of the heat pump frenette was substantially changed. The rotor shaft remains in a horizontal position, but the inner part was made of two rotating drums and placed between them the impeller. As the coolant is used again here liquid oil.

In this embodiment, the heat pump Frenette two tilera revolve around, they are separated by an impeller of special design, made from very durable metal

During the rotation of this design the oil is further heated as it goes through the holes made in the impeller, and then enters a narrow cavity between the walls of the pump casing and rotor. Thus, the efficiency of the pump Frenette was significantly increased.

The edges of the impeller for the heat pump Frenette made a small hole. The coolant is quickly and effectively heated passing through them

However, it should be noted that for making at home this type of pump is not ideal. To start you will need to find reliable drawings or to calculate the design of their own, and it is only by an experienced engineer. You will then need to find a special impeller with holes of a suitable size. This element of the heat pump is operating at high loads, so it needs to be made of very durable materials.

Independent production device

Overview of the device variants of the pump Frenette allows you to understand that how it works with varying degree of effectiveness can be used in constructions of different type and kind. The basic idea remains the same: the narrow space between the elements of metal, filled with oil, and rotation by an electric motor.

The diagram shows a variant of the heat pump Frenette, which is commonly used for manufacturing the device. The basis of design — metal disks separated nuts (+)

At home, most often made pump Frenette, consisting of a series of metal plates separated by a narrow space. To fabricate such a device, all you need to begin to find and prepare the necessary materials:

- a hollow cylinder of metal;

- a set of identical steel disks with a hole in the center.

- a set of nuts height 6 mm;

- steel rod with thread:

- motor with extended shaft;

- bearing;

- radiator;

- the connecting pipe.

It is obvious that the hole in the disk should be such that they can be freely put on the axial rod. The outer diameter of the disc should be less of the case by a few millimeters. If you are willing elements at hand was not, the wheels cut their own sheet metal, or assign this work to Turner.

The cylindrical body can be made from old metal containers suitable configuration or weld metal. And fit a piece of wide metal pipe. To the ends of the cylinder is welded to the wall. The enclosure must be sealed so that the oil does not leak. In the upper and lower end of the body should make additional holes: inlet and outlet heating pipes leading to the radiator.

Of course, all of the joints of the pipes should be sealed. For threaded connections use special seals: FUM-feed, flax, etc. If you decide to use PVC pipe, you will need special fittings and possibly a soldering iron for the installation of these pipes.

For pump operation Frenette high-performance motor is not needed. Suitable device, taken with the old or broken home appliances, for example, with a normal fan. The main purpose for the motor to rotate the shaft. Excessively rapid rotation may cause incorrect operation of the device. The faster the rotation design, the greater the heat the coolant.

Small engine crank shaft of the heat pump Frenette can be removed with broken appliances or to buy at the store

To the rod spun freely, needs a suitable bearing in standard sizes. When all the elements prepared, you can start assembling the device. First, on the lower part inside the housing installing the Central axis with the bearing. Then, on the axis of the separation nut is screwed and put on a disk, nut, disk, etc.

Drives nuts to alternate until the case is filled to the brim. At the stage of preparation it is possible to make preliminary calculations on the number of necessary discs and nuts. Need to the thickness of the nut (6 mm) was added to the thickness of the disk. The height of the housing is divided by this figure. The resulting number will give information about the desired number of pairs of “nut+disc”. The latter set the nut.

After the case is filled with these moving parts, it is filled with liquid oil. The oil type doesn't matter, you can take mineral, cottonseed, rapeseed or any other oil that tolerates heat and does not freeze. After that the design cover with the top cover and gently sealed.

By this time cooler pipes is normally attached to the lids. For convenience during the further installation and maintenance on the pipes you can put two of stopcock. Now on to the motor shaft connecting the axle of the heat pump. System include the network, check for leaks, evaluate the performance of the device.

Made heat pump Frenette can be connected to a conventional cast-iron or bimetal radiator, which will provide the necessary heating effect

If done correctly, the axis with the disks starts to spin, warming up inside the device oil. Hot coolant will move through the upper hole on the tube in the radiator. The cooled oil will return to the case of a heat pump in the down pipe for re-heating.

To automate the system, you can use special relays with a temperature sensor that detects heating of the case of the heat pump and stops the engine or turns it on as needed. This will prevent overheating of the system, the hazards in General will increase the life of the device.

An interesting variant of the pump Frenette presented in this video:

Put LIKES and share with your FRIENDS!

www.youtube.com/channel/UCXd71u0w04qcwk32c8kY2BA/videos

The following video shows a successful experience of start of the heat generator in which water is used:

Put LIKES and share with your FRIENDS!

www.youtube.com/channel/UCXd71u0w04qcwk32c8kY2BA/videos

Unfortunately, the pump Frenette not found wide acceptance in the field of heating. Such a device of industrial production for domestic use is difficult to find in stores equipment for home. But many folk artists have successfully used the achievements of this scientist and applied them in their residences, baths, garages, etc.

P. S. And remember, only by changing their consumption — together we change the world! ©

Source: sovet-ingenera.com/eco-energy/teplovye-nasosy/teplovoj-nasos-frenetta-svoimi-rukami.html

Kinesiological technique of "Cross-crawl" — access the potential of the brain and body

Vaccination as a possible cause of autism