167

vortex hydraulic heat generator

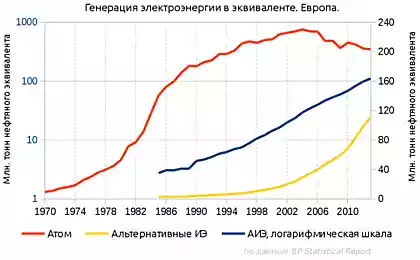

Currently, in agriculture there is a task of widespread introduction of energy-saving technologies that will reduce material resources in the creation of new products and reduce energy costs in this process. Alternative energy sources are a promising direction for this.

One of the alternative types of renewable energy is vortex, which is a technology for using swirling streams of continuous medium (for example, liquid and gas) to convert them into thermal energy, work, temperature and pressure gradient.

Traditional heat generators, which are widely used in technology and everyday life, are energy converters that use the heat of combustion of various fuels (liquid, solid and gaseous). Their disadvantages include pollution of the environment by combustion products, significant financial costs in the transportation and storage of energy carriers.

Another thing is the development of an autonomous, small-sized, economical, flexible in operation and technically safe thermal power plant - "Whirlwind hydraulic heat generator" (VGT).

The installation was created in the Federal State Budgetary Institution VIESH together with SSAKU VGT - this is one of the directions in solving the problem of providing the needs of the population, industry and agriculture with thermal energy, especially in regions remote from centralized energy networks. The device generates heat by changing the physical and mechanical parameters of the liquid medium during its flow under the complex influence of accelerated and inhibited movement. Acceleration of the flow is achieved by creating a vortex in the systems of swirling the flow of the vortex heat generator with simultaneous narrowing of the flow in the confusor, and braking - its subsequent expansion in the cavitation pipe of the heat generator and the expansion of the flow at the exit of the cavitation pipe.

The HGT-based heat supply system consists of a flow swirling system 1, a cavitation pipe 2, a vortex 3, heat transfer devices (heat exchanger, batteries, radiators, etc.) 4, a hydraulic pump 5 with an electric motor 6 and a heat generator 7 control panel.

The scheme of decentralized heat supply system based on VGT As a heat source, a miniature vortex heat generator (VGT) operating from a hydropump is used. Electricity is used only to power the hydropump drive of the heating system, and the hydropump is powered by electricity only to heat the water. When the heating system cools to a predetermined temperature - the hydraulic pump is turned off (the machine controls the specified air temperature in the room). Therefore, a hydraulic pump, for example, with a capacity of 1 kW, actually consumes only 0.5 kW during an hour of operation, and a hydraulic pump with a capacity of 0.6 kW only consumes 0.3 kW. The test results show that with a hydraulic pump with a capacity of 1.0 kW, the water in the heating system is heated to a temperature above +60 ° C with an electricity consumption of up to 17-19 kWh, and with a hydraulic pump with a capacity of 0.6 kW - about +50 ° C with an electricity consumption of up to 12-14 kWh.

Features of vortex hydraulic heat generator are:

- The thermal power of the pilot plant (0.5...5) kW to provide heat to the premises;

- the device is environmentally friendly, there is no need to burn hydrocarbon fuels (coal, oil, gas);

There are no heating elements;

Electricity is used only to power the hydropump drive;

There is no need for water treatment;

- can heat any liquid (water, oil, gas condensate...);

provides automatic maintenance of the temperature of the coolant in a given temperature range;

Economical in operation and maintenance.

The range of use of HGT is quite wide and flexible, for example, the design presented here can work with hydraulic pumps up to 5 kW. In addition, HGT can be configured to maintain any temperature in the room - so, HGT with a capacity of 1.0 kW will provide +12 ° C in a barn of up to 160 m2, and the same HGT with a hydraulic pump of 2.5 kW will provide +12 ° C in a barn of up to 550 m2.

Authors: V.V. Biryuk, R.A. Serebryakov

P.S. And remember, just changing our consumption – together we change the world!

Join us on Facebook, VKontakte, Odnoklassniki

Source: alternativenergy.ru

One of the alternative types of renewable energy is vortex, which is a technology for using swirling streams of continuous medium (for example, liquid and gas) to convert them into thermal energy, work, temperature and pressure gradient.

Traditional heat generators, which are widely used in technology and everyday life, are energy converters that use the heat of combustion of various fuels (liquid, solid and gaseous). Their disadvantages include pollution of the environment by combustion products, significant financial costs in the transportation and storage of energy carriers.

Another thing is the development of an autonomous, small-sized, economical, flexible in operation and technically safe thermal power plant - "Whirlwind hydraulic heat generator" (VGT).

The installation was created in the Federal State Budgetary Institution VIESH together with SSAKU VGT - this is one of the directions in solving the problem of providing the needs of the population, industry and agriculture with thermal energy, especially in regions remote from centralized energy networks. The device generates heat by changing the physical and mechanical parameters of the liquid medium during its flow under the complex influence of accelerated and inhibited movement. Acceleration of the flow is achieved by creating a vortex in the systems of swirling the flow of the vortex heat generator with simultaneous narrowing of the flow in the confusor, and braking - its subsequent expansion in the cavitation pipe of the heat generator and the expansion of the flow at the exit of the cavitation pipe.

The HGT-based heat supply system consists of a flow swirling system 1, a cavitation pipe 2, a vortex 3, heat transfer devices (heat exchanger, batteries, radiators, etc.) 4, a hydraulic pump 5 with an electric motor 6 and a heat generator 7 control panel.

The scheme of decentralized heat supply system based on VGT As a heat source, a miniature vortex heat generator (VGT) operating from a hydropump is used. Electricity is used only to power the hydropump drive of the heating system, and the hydropump is powered by electricity only to heat the water. When the heating system cools to a predetermined temperature - the hydraulic pump is turned off (the machine controls the specified air temperature in the room). Therefore, a hydraulic pump, for example, with a capacity of 1 kW, actually consumes only 0.5 kW during an hour of operation, and a hydraulic pump with a capacity of 0.6 kW only consumes 0.3 kW. The test results show that with a hydraulic pump with a capacity of 1.0 kW, the water in the heating system is heated to a temperature above +60 ° C with an electricity consumption of up to 17-19 kWh, and with a hydraulic pump with a capacity of 0.6 kW - about +50 ° C with an electricity consumption of up to 12-14 kWh.

Features of vortex hydraulic heat generator are:

- The thermal power of the pilot plant (0.5...5) kW to provide heat to the premises;

- the device is environmentally friendly, there is no need to burn hydrocarbon fuels (coal, oil, gas);

There are no heating elements;

Electricity is used only to power the hydropump drive;

There is no need for water treatment;

- can heat any liquid (water, oil, gas condensate...);

provides automatic maintenance of the temperature of the coolant in a given temperature range;

Economical in operation and maintenance.

The range of use of HGT is quite wide and flexible, for example, the design presented here can work with hydraulic pumps up to 5 kW. In addition, HGT can be configured to maintain any temperature in the room - so, HGT with a capacity of 1.0 kW will provide +12 ° C in a barn of up to 160 m2, and the same HGT with a hydraulic pump of 2.5 kW will provide +12 ° C in a barn of up to 550 m2.

Authors: V.V. Biryuk, R.A. Serebryakov

P.S. And remember, just changing our consumption – together we change the world!

Join us on Facebook, VKontakte, Odnoklassniki

Source: alternativenergy.ru