188

How to make a Frenett heat pump with your own hands

Quite an interesting development that allows you to provide heating of various rooms - Frenett heat pump (with your own hands to create such a unit is quite simple, it is possible for any folk craftsman), which does not require any types of fuel.

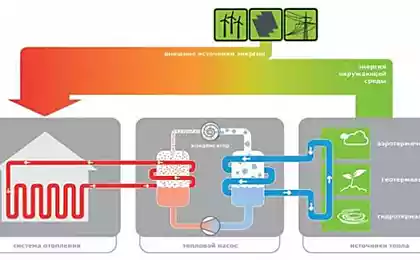

It is worth mentioning that, despite the similarity of the name, this installation has nothing to do with geothermal heat pumps, these designs work on a completely different principle.

The basic principle of operation of the Frenett installationFrom the school course of physics it is known that the force of friction between different substances can lead to their heating to sufficiently high temperatures. It was this feature that was put by the inventor Eugene Frenett in the basis of the thermal device he created.

Frenett heat pumps have undergone many changes, the design of the device has been significantly modified and improved, but the basic principle of operation has remained the same.

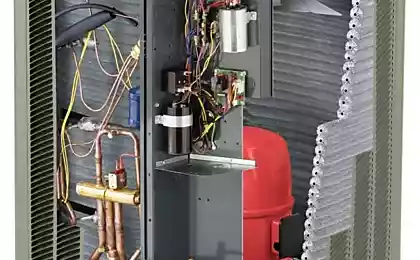

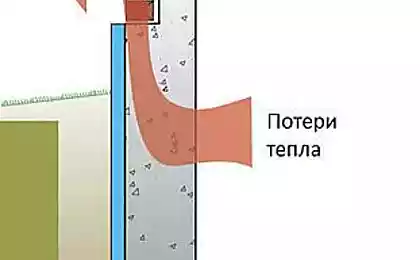

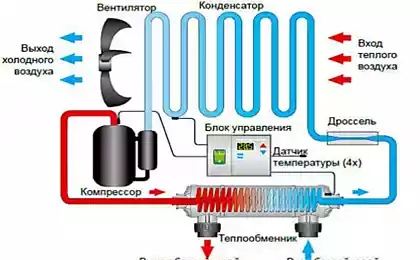

Pump of this type consists of two vessels placed one inside the other, the space between them is filled with technical oil. The inner cylinder is connected to the shaft of the electric motor, rotating at high speed. Due to this, under the influence of friction forces between the surfaces of the cylinders and the coolant (oil), it is heated to sufficiently high temperatures.

The resulting thermal energy is transferred to a traditional heating radiator (oil comes to it through pipeline systems) or used to heat the air, from which heat flows are formed using the built-in impeller. According to the manufacturers, the principle of operation of the Frenett heat pump allows you to get a device whose efficiency reaches 1000%, of course, it is difficult to believe this (again, based on the usual school knowledge of physics), but it is worth admitting that the effectiveness of the design of the device is very difficult.

First of all, it is worth noting the fact that oil should be used as a coolant, which has a higher boiling point (compared to water). Of course, there are water modifications of pumps, but they have a more complex design. This is due to the fact that the energy obtained as a result of friction is enough to transition water into a vapor state, resulting in excessive pressure in the system, which leads to the need to improve the reliability of all components of the structure.

In practice, factory plants and homemade Frenett pumps are used, the following modifications are most common:

Frenett heat pump model

The inner cylinder is a mushroom-like structure. During the operation of the pump, the coolant (water) is heated to a boil and turns into steam, the resulting reactive forces ensure its movement through the internal channels of the installation at a high speed (reaching 135 meters per minute). This ensures high efficiency of the installation.

All factory modifications have a fairly high cost, so the designs that can be independently assembled at home are of particular interest.

Frenett's homemade pump

To mount the Frenett pump with your own hands is quite simple, while you do not need expensive parts and structural components. The installation does not require the use of additional impellers, and the functions of the inner cylinder are performed by several conventional steel disks placed on the drive shaft. So, the main elements of a homemade heating system, working on the principle of the Frenett heat pump:

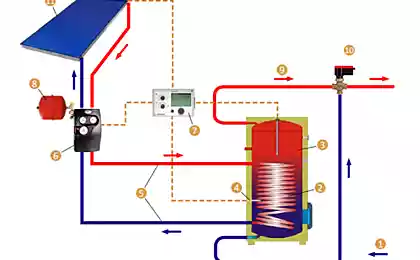

In the case of the installation (outer cylinder) make two holes (top and bottom). Through the upper heated oil will be supplied to the heating system, and the lower hole is used to return it to the installation.

After assembly of the main components of the pump, it is necessary to fill it with oil, connect the working axis and electric drive, the inlet and outlet pipe to the heating line. After sealing the structure, you can start a homemade Frenett pump in operation.

To simplify the management of the device, make its operation more convenient and efficient, it is recommended to assemble an automatic control system that is able to enable the installation when the temperature in the room decreases to a certain critical value.Area of application of heat pumps

In principle, devices of this type can be used to heat a variety of rooms, ranging from garages, outbuildings, residential and industrial buildings, there are no restrictions in this matter.

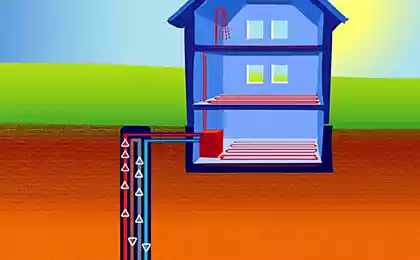

If you use the Frenett pump to heat a separate room or room, it is advisable to connect it to conventional heating radiators. When using this device to provide heating in a residential building, it is worth considering the possibility of its joint operation with water heating floor systems. This solution provides the most efficient heating. In this case, the sensor that ensures automatic operation is installed in the pump housing, rather than in the screed (as for traditional floor heating systems).

Despite the fact that the efficiency of such a simple device is difficult to believe, practice shows its reliability and high performance. Therefore, if you are thinking about providing non-volatile heating, be sure to consider installing Frenett pumps.

P.S. And remember, just changing our consumption – together we change the world!

Join us on Facebook, VKontakte, Odnoklassniki

Source: canalizator-pro.ru/ustrojstvo-i-princip-dejstviya-teplovogo-nasosa-frenetta.html

It is worth mentioning that, despite the similarity of the name, this installation has nothing to do with geothermal heat pumps, these designs work on a completely different principle.

The basic principle of operation of the Frenett installationFrom the school course of physics it is known that the force of friction between different substances can lead to their heating to sufficiently high temperatures. It was this feature that was put by the inventor Eugene Frenett in the basis of the thermal device he created.

Frenett heat pumps have undergone many changes, the design of the device has been significantly modified and improved, but the basic principle of operation has remained the same.

Pump of this type consists of two vessels placed one inside the other, the space between them is filled with technical oil. The inner cylinder is connected to the shaft of the electric motor, rotating at high speed. Due to this, under the influence of friction forces between the surfaces of the cylinders and the coolant (oil), it is heated to sufficiently high temperatures.

The resulting thermal energy is transferred to a traditional heating radiator (oil comes to it through pipeline systems) or used to heat the air, from which heat flows are formed using the built-in impeller. According to the manufacturers, the principle of operation of the Frenett heat pump allows you to get a device whose efficiency reaches 1000%, of course, it is difficult to believe this (again, based on the usual school knowledge of physics), but it is worth admitting that the effectiveness of the design of the device is very difficult.

First of all, it is worth noting the fact that oil should be used as a coolant, which has a higher boiling point (compared to water). Of course, there are water modifications of pumps, but they have a more complex design. This is due to the fact that the energy obtained as a result of friction is enough to transition water into a vapor state, resulting in excessive pressure in the system, which leads to the need to improve the reliability of all components of the structure.

In practice, factory plants and homemade Frenett pumps are used, the following modifications are most common:

- Pumps with a horizontal arrangement of working cylinders (drums) have small overall dimensions. There are models in which the role of the internal cylinder is played by the shaft of the electric motor, which allows you to significantly simplify the design. But at the same time, it is worth paying special attention to sealing all the nodes with the help of glands, rubber cuffs and other similar elements, the flow of the coolant is not allowed. This Frenetta pump heats the oil and feeds it into a traditional heater.

- The device, capable of working with increased efficiency, is a design of two working drums and impeller. The centrifugal force that occurs when the fluid is unwinded by the impeller leads to the release of oil into the minimum gap between the surfaces of the cylinders. At the same time, the amount of thermal energy released under the action of friction forces increases significantly. This design is also connected to household heating radiators.

- An industrial plant operating on the principle of a Frenett pump, in which water is used as a coolant, is able to operate without an external supply device. Remember that it is almost impossible to create such an installation at home, it is of interest only on an industrial scale.

Frenett heat pump model

The inner cylinder is a mushroom-like structure. During the operation of the pump, the coolant (water) is heated to a boil and turns into steam, the resulting reactive forces ensure its movement through the internal channels of the installation at a high speed (reaching 135 meters per minute). This ensures high efficiency of the installation.

All factory modifications have a fairly high cost, so the designs that can be independently assembled at home are of particular interest.

Frenett's homemade pump

To mount the Frenett pump with your own hands is quite simple, while you do not need expensive parts and structural components. The installation does not require the use of additional impellers, and the functions of the inner cylinder are performed by several conventional steel disks placed on the drive shaft. So, the main elements of a homemade heating system, working on the principle of the Frenett heat pump:

- Steel outer cylinder of suitable diameter.

- Metal discs that are slightly smaller than the internal diameter of the cylinder. Remember that the efficiency of the device will increase as the gap between the structural elements decreases.

- A small electric motor with an elongated shaft on which internal disks are mounted.

- Mineral or other technical oil (for example, rapeseed or cotton).

- A system of pipelines that ensure the circulation of the coolant and household heating radiator.

In the case of the installation (outer cylinder) make two holes (top and bottom). Through the upper heated oil will be supplied to the heating system, and the lower hole is used to return it to the installation.

After assembly of the main components of the pump, it is necessary to fill it with oil, connect the working axis and electric drive, the inlet and outlet pipe to the heating line. After sealing the structure, you can start a homemade Frenett pump in operation.

To simplify the management of the device, make its operation more convenient and efficient, it is recommended to assemble an automatic control system that is able to enable the installation when the temperature in the room decreases to a certain critical value.Area of application of heat pumps

In principle, devices of this type can be used to heat a variety of rooms, ranging from garages, outbuildings, residential and industrial buildings, there are no restrictions in this matter.

If you use the Frenett pump to heat a separate room or room, it is advisable to connect it to conventional heating radiators. When using this device to provide heating in a residential building, it is worth considering the possibility of its joint operation with water heating floor systems. This solution provides the most efficient heating. In this case, the sensor that ensures automatic operation is installed in the pump housing, rather than in the screed (as for traditional floor heating systems).

Despite the fact that the efficiency of such a simple device is difficult to believe, practice shows its reliability and high performance. Therefore, if you are thinking about providing non-volatile heating, be sure to consider installing Frenett pumps.

P.S. And remember, just changing our consumption – together we change the world!

Join us on Facebook, VKontakte, Odnoklassniki

Source: canalizator-pro.ru/ustrojstvo-i-princip-dejstviya-teplovogo-nasosa-frenetta.html