453

Nike and Adidas are using 3D printers in the production of sneakers

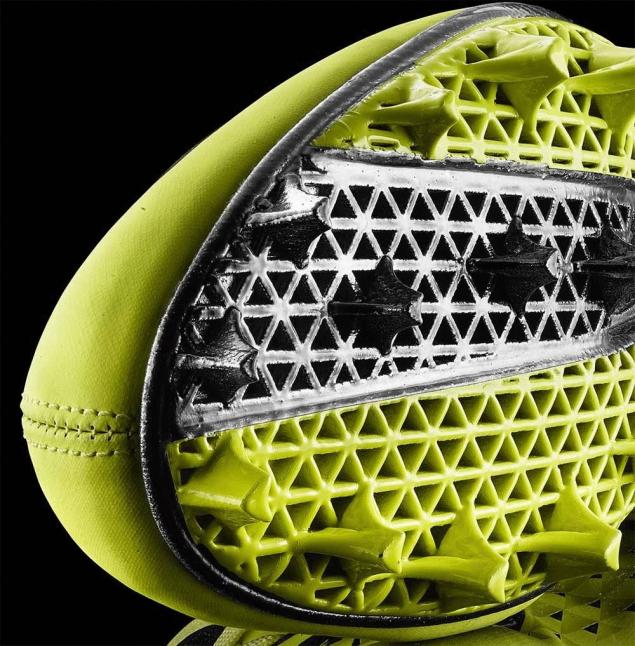

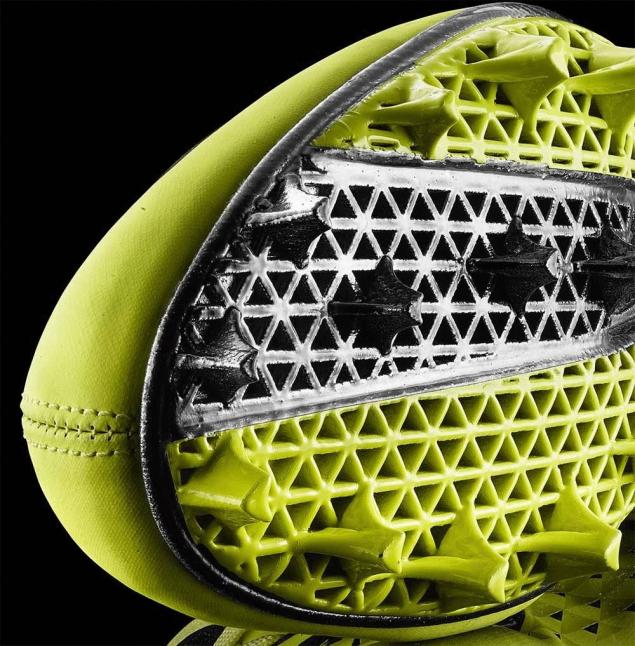

Manufacturers of sports shoes Nike and Adidas have introduced in footwear manufacturing technology of 3D printing.

With the help of a 3D printer the company makes samples of soles with a complex pattern, like running shoes or football boots. Not so long ago the samples were obtained by molding, when the steel form is poured melted plastic and waited for it to harden. It was a pretty long procedure.

3D printing has provided an opportunity to accelerate the development of new models of shoes, which involves the creation of multiple samples. Nike experts say that six months made 12 test cycles, and Adidas noted that a new sample, through the use of 3D printing has decreased from 4-6 weeks to just 1-2 days.

The representative of Adidas company stresses that the creation of the sample soles with 3D printing involved a lot less people than in the creation of the usual casting method: 2 people instead of 12.

Source: /users/413

With the help of a 3D printer the company makes samples of soles with a complex pattern, like running shoes or football boots. Not so long ago the samples were obtained by molding, when the steel form is poured melted plastic and waited for it to harden. It was a pretty long procedure.

3D printing has provided an opportunity to accelerate the development of new models of shoes, which involves the creation of multiple samples. Nike experts say that six months made 12 test cycles, and Adidas noted that a new sample, through the use of 3D printing has decreased from 4-6 weeks to just 1-2 days.

The representative of Adidas company stresses that the creation of the sample soles with 3D printing involved a lot less people than in the creation of the usual casting method: 2 people instead of 12.

Source: /users/413