175

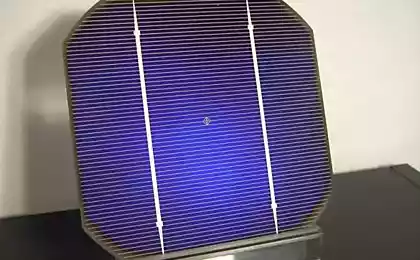

Innovative coating that extends the life of thermal solar panels

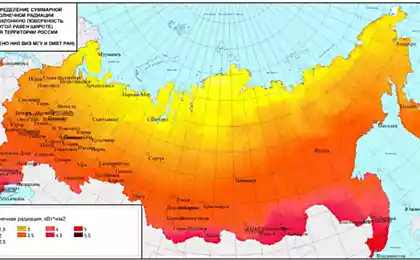

Swiss researchers from the Federal Institute of Technology in Lausanne have created a black coating for thermal solar panels that retains its original color much longer than traditional materials. Its use will extend the life of the panels and thus improve the overall efficiency of solar energy harvesting.

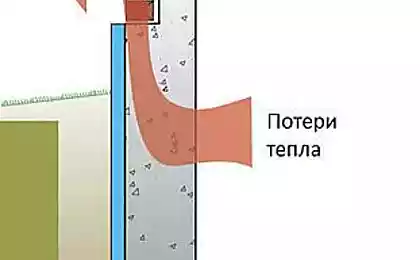

As with most structural elements of the building, the lifespan of thermal solar panels should be at least 25-30 years. During their operation, the average temperature is about 80 ° C, rising in the summer to 200 ° C. At this temperature, it is quite difficult to ensure reliable operation of devices for such a long time, given the continuous exposure to air and atmospheric moisture.

To slow the aging process and ensure the long-term performance of solar heating systems, the researchers improved the black coating used for heaters and developed an original patented method for applying it.

Black is a key element of the efficiency of thermal panels, thanks to which 90% of the incoming energy is captured. But over time, any coating loses its positive properties, black ceases to be black, and the panel becomes less effective.

The innovative process developed in Lausanne involves the application of thin layers of three different materials, more resistant and less toxic than the chromium currently used in panels. The new material provides high strength in the open air at temperatures up to 300-400 ° C, which will eliminate the use of expensive glass vacuum tubes.

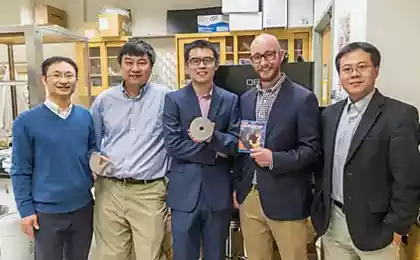

Exceptional resistance to high temperatures was provided by the use of nanocrystals in the coating. The new multi-layered black material, designed to replace the traditional chromium that dominates the market today, consists of cobalt, manganese and copper. Manganese provides a stable black color, cobalt - high resistance to corrosion, and copper - ideal thermal conductivity.

“We wanted to develop selective layers that absorb light well but are less toxic than chromium, and so we looked at these materials,” said Andreas Schüler, head of the research team. As it turned out, the multilayer material, applied chemically, has exceptional heat resistance, previously unattainable with the use of chromium-based coatings. Without deterioration of properties, the material withstands a temperature of 360 ° C in the air.

The new coating is applied to the steel tubes of the panels by sequential immersion in nanomaterials with induction heating of each layer, which allows the elements to fix and remove carbon.

According to Andreas Schuler, the method, for the commercial use of which the technology has yet to be developed, due to its ability to tolerate high temperatures, can be used not only in thermal solar panels, but also in thermal power plants.

Source: facepla.net