603

Dietary Supplement became the basis of low-cost solar panels

Scientists from the University of the state of North Carolina and the Chinese Academy of Sciences have discovered a technique of manufacturing solar panels without the use of hazardous halogenated solvents. A poisonous substance replacing conventional flavoring agent that is used in the food industry. Batteries of this type can be produced at room temperature, which opens possibilities for mass production without harming the environment. Organic photovoltaic cells are lightweight, are flexible, transparent and low cost in production. But with the release of these solar panels uses toxic halogen solvents which can be used only in a special controlled environment — this requires additional costs and increases the retail cost of panels. A group of physicists decided to find an equally effective substance to create the structure of solar panels, but without the toxic properties.

Scientists were able to develop a prototype plastic solar panels on the basis of on-methylanisole (o-MA) as solvent. O-MA has no toxicity and traditionally used as a flavor enhancer for various foods.

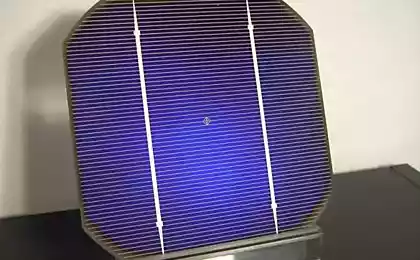

The structure of the obtained solar panels was studied by means of soft x-rays. The analysis has found that solar cells based on o-MA have a similar structure as the panel created by using halogenated solvents. They have good carrying capacities and a conversion gain of about 8.4%.

Panels of this type can be produced in the open air at room temperature by using a doctor plate. This technique allows you to do mass production of solar cells on a large scale.

According to estimates by Bloomberg, from-for oversaturation of the market value of solar panels in 2017 will be reduced by 20%. However, the cost of production is not the only problem in the manufacture of solar panels. Engineers and physicists strive to achieve maximum efficiency, working to improve the flexibility and decrease the size of the solar panels, as well as inspired by the rose petals to enhance the efficiency of thin film solar panels. published

Source: hightech.fm/2016/10/03/o_ma

Scientists were able to develop a prototype plastic solar panels on the basis of on-methylanisole (o-MA) as solvent. O-MA has no toxicity and traditionally used as a flavor enhancer for various foods.

The structure of the obtained solar panels was studied by means of soft x-rays. The analysis has found that solar cells based on o-MA have a similar structure as the panel created by using halogenated solvents. They have good carrying capacities and a conversion gain of about 8.4%.

Panels of this type can be produced in the open air at room temperature by using a doctor plate. This technique allows you to do mass production of solar cells on a large scale.

According to estimates by Bloomberg, from-for oversaturation of the market value of solar panels in 2017 will be reduced by 20%. However, the cost of production is not the only problem in the manufacture of solar panels. Engineers and physicists strive to achieve maximum efficiency, working to improve the flexibility and decrease the size of the solar panels, as well as inspired by the rose petals to enhance the efficiency of thin film solar panels. published

Source: hightech.fm/2016/10/03/o_ma