1963

Complete energy autonomy or how to survive with solar panels in the province (Part 2. Practical)

The actual solar avtonomka for the end user is made up of the money spent, the samples mounted devices and training of households use electricity sparingly. Moreover, the last paragraph should pay attention especially because avtonomka assumes a very special approach to energy consumption and even restructuring habitual actions.

Since solar panels are the most visible part of the system, and even convert the sun's energy into electricity, then it should start with them. There are two ways to obtain the solar cell: do it yourself or buy ready-made. I must say that the total cost of the final product in the manufacture of several panels and without experience will cost about the same amount as the final panel of the same capacity, but produced at the plant. But it is interesting to do.

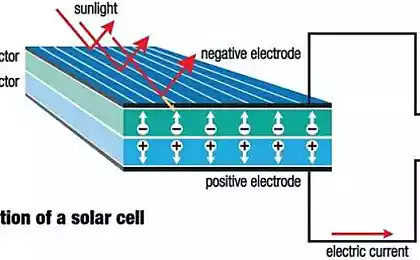

Here we must again add a little theory. There are three available to customers for sane money, technology solar cells composed of different cells: monocrystalline, polycrystalline and amorphous silicon. They differ in structure and can even see it in the eyes. I will try to explain as simply as possible, and those wishing to experience the difference in chemical compositions can view the information for yourself - do not overload the article.

Amorphous silicon - the most promising technology for manufacturing. Allows to make bendable panel and supply current when the scattered light that is in cloudy weather, but quickly degraded, resulting in a decrease in efficiency.

Single crystal - pure silicon cells from the primary. As a rule, black plate without inclusions, almost square shape with rounded edges. Sometimes sawn in half to increase the voltage line elements.

Polycrystalline - silicon cells from secondary or not very clean. Probably used scrap of a single crystal.

Types of batteries are arranged in descending order of value. And if the second and third options are still close, the first noticeable breaks in the cost of, and eventually reduces the production of energy. To manufacture its own solar panels (the joint venture or SB - Solar Battery) in China was commissioned party solar cells Class Grade B (read about the classification of elements can HERE ) number for a couple of the Security Council. You need to check that the set includes terminal boxes, bus for connecting the cells to each other and at least a couple of meters of cable. There were also ordered MC4 connectors for connecting batteries. In Russia, was commissioned by the enlightened manufacturing toughened glass 4 mm thick. This thickness is due to the need to protect themselves from any icicles (hail) and other weather conditions (focused with a stone unlikely to survive), and enlightened glass need to increase the efficiency of elements. For framing glass, protection from chips and ease of installation was purchased aluminum corner 30x30 and necessary hardware to it. To connect the solar system was chosen stranded copper cable with a cross section of 6 mm square. To charge was booked in the same China Controller PWM, and for power supply 220V - simple car inverter power of 100 watts Chinese. Later I will explain the difference between conventional and Chinese Watts.

The energy system №1. Budget

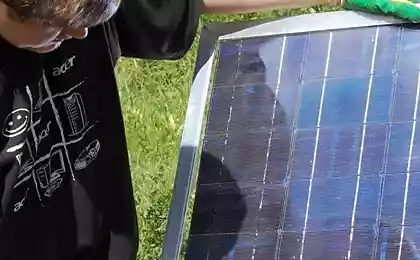

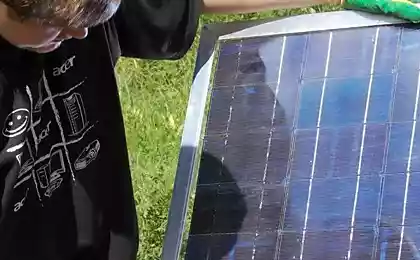

Self-production of solar panel

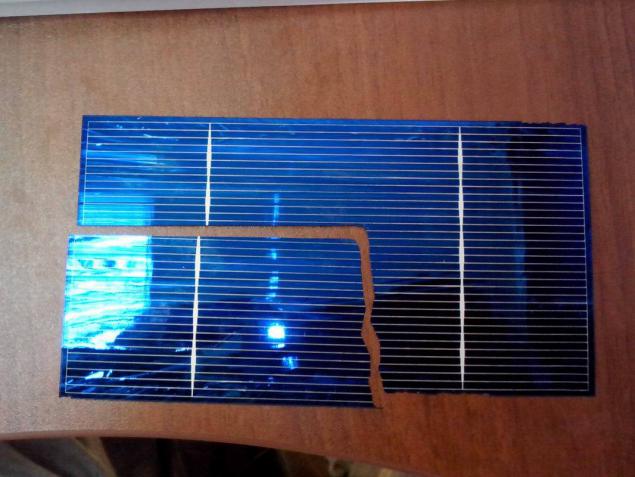

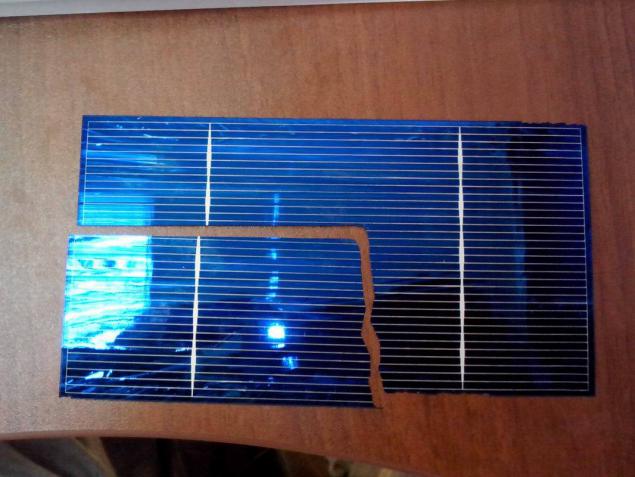

Thus, the assembly. Modules come in a box and some of them were broken, as in the first photograph. To this end, the stock usually has about 10 pieces. I complained in a letter to the Chinese, and he sent me a free 10 more cells. Each cell gave 0, 5 and 4 A statement by Chinese merchants. That is, each module 2 watts. To charge the battery must have the voltage is above 14 volts 4, that is, it is necessary to merge cells in series. Looking at the factory panels and using the practice of many Homebrew, it was decided to combine the two in one glass chain for 36 elements to give 18 volts and 8A peak. That is one panel could bring up to 144 watts of power, which has never happened. Causes look at later, but for now manufacturing.

The procedure is simple. Solder shank:

Cooking glass with frame:

Puts solder, bus terminals and solder wires, and then pour a special compound to seal all the plates. People poured sealant, various mastics, I liked ready compound manufacturing company in St. Petersburg. It's nice that Russian production, so give money was not sorry, and the result is pleasantly pleased. The conclusions of the contacts would be good to priladit sealed box with a diode that will prevent a drop in the power system is connected in series, if one of the batteries will be darkened. The box came with cells.

As a result, I got two solar panels with a rated output of 288 Вт.

But then there are lots of conventions. When heated, the efficiency of the solar panel it even decreases the calculated percent 20. Moreover, influences nepropay elements and microcracks, which inevitably arise during soldering. As a result of measurement in the summer sun I got a 40 watt each panel, that is, the result is three times smaller than expected. The price of this panel came around 6000-6500 rubles, while the factory panel treated with delivery in 7000-7500 rubles. So I finished the initiative to continue to buy only original panel.

Selecting a base voltage

Perhaps this is one of the first decisions that must be taken in the design of solar panels. The fact that the systems are solar-powered with a voltage that is a multiple of 12 - in fact, most batteries have just such a strain. Even battery-capacity collected from cells at 2B is often collected at 12, 24, 36 or 48 volts. You've got to remember physics and electrical power formula: P = U * I. From this it follows that the same power, increasing the voltage, we will reduce the current. Quite naturally, the decrease in the current would entail reducing the load on the element base and reduced wire sizes, but also infinitely increase the voltage can not be. Then there is the following problem: DC, unlike AC voltage increases above 36 volts is far more dangerous to humans. If you do not delve into the theory, the AC voltage to 220V hand tear often possible, but the constant is almost never. In addition to this low voltage can vote, if only because that 12V - a typical car battery voltage, which means there are many different techniques designed for this voltage. In addition, the capacity of the storage capacity can be easily added in parallel to conventional batteries, while a higher voltage would have to buy batteries in pairs, threes or fours. There is another unpleasant moment in the series connection of batteries: imbalance of cells, which leads to the failure of the first one cell, then the whole of the battery and the entire chain, if time does not track down the problem.

My choice: 12

Selecting a charge controller solar powered

There are two basic types of controllers: PWM or PWM controller and MPPT or Maximum Power Point Tracking - Tracking the maximum power point.

The first type is as simple and familiar with PWM no need to explain, but for the rest of the most simple: to achieve the maximum level of the battery, the controller issues a ripple current to the battery, not letting recharge. Plus this scheme: simplicity, and therefore, low cost. Minus: You can connect the battery nominal voltage of which coincides with the nominal value of the battery voltage.

MPPT controllers are difficult, expensive, but have a great advantage: the solar batteries can be connected in series, thereby increasing the tension in the chain to the controller, and reducing the current, which allows the use of thinner wires and reduce losses in energy transmission to the controller. And the efficiency of such controllers is higher because they are scanned at regular intervals currents at different voltages and choose a point of maximum power. Hence the name. Those who wish to plunge into the world of technology, you can go here , where quite sensibly and detail painted.

By its own panels I bought Chinese PWM-controller, giving charge to 30A, ie 360 W at 12 V or 720 watts at 24V. But because the system is selected to 12V, the limit - it is 30A or 3 solar panels are connected in parallel.

Add to it ordered from the same voltmeter and ammeter to see the condition of the battery and a charge enters the battery. The battery has been chosen the cheapest lead acid, with a capacity of 190 Ah, because I still believed that I was about to be connected electricity network.

Select the inverter

Turn to the most entertaining point of our system. Let's start with the fact that the inverters, in addition to power, easily divided into two types: with pure sine wave output and a modified sine wave (also referred approximated sine wave or square wave). The first issue pure sine wave, while the latter have a step on the chart:

For most equipment is no difference, and if you connect a simple voltmeter, his testimony will be about the same. But if you compare the prices of both types of devices of the same power, it turns out that the price is different order of magnitude. Do I have to pay for a pure sine and what is it for? B> As shown, most devices are easy to get along with a modified sine wave, although some engines, such as compressors, refrigerators, start to warm up more and increases the risk of premature system. In addition, if you connect to a modified sine wave audio equipment, you will hear a rattling noise, which is not happy, when you want to enjoy a good sound. From my own experience I can say that from a modified sine wave refused to work only washing machine - all other devices worked successfully. If there is a good amount for the inverter, you should choose pure sine if other devices are sensitive to the purity of the signal.

We select the inverter capacity

In this regard, a lot of nuances that affect the choice of the inverter. The rule is: the whole is summed planned load power and multiplied by two. For example: 4 lamps of 60 watts + 800 watts washing machine + laptop + 80 watts 100 watts + Refrigerator TV 50 watts. It would seem that the maximum power consumption is 240 + 800 + 80 + 100 + 50 = 1270 watt inverter and enough to take on the 1300-1500 watts, but! Various load behave differently. For example, the starting current can be up to ten times cooler values during the launch, which means it will require 1 kW of power immediately, and if at that time will be included light and washing machine, the inverter simply fall into the error, if you do not burn. In addition, Chinese inverters такого type 1500 W were unable to run the refrigerator with a rated power of 100 W power consumption. Experiment was carried out when the refrigerator started from the generator, and then quickly switched to the inverter with the switch phases. So was able to feed from the Chinese refrigerator inverter 600W - barbarism, it is difficult, but it works. The trouble is one thing a second time to launch such an inverter refrigerator not. Cheating was whether to put a refrigerator setting the maximum frost. And fridge freezes up until you turn it off. So it is possible for the light day namorozit products, and at night to disable it.

Thus, the capacity of the inverter must be such as to ensure a two-time reserve your consumption of conventional instruments or ten times to start the engine.

My choice: two Chinese inverter capacity of 1,000 and 600 watts.

Duplicate

When choosing a cheap and simple accessories it is better to be put on back-up systems. This will not remain without electricity in the event of failure of any element. Such reassurance would not be expensive, but will provide peace of mind and a stable power supply.

In general, the first set avtonomki looked like:

1. Two homemade solar panels with a total capacity of 80 W

2. PWM- Charge controller with maximum current up to 30A

3. automobile lead-acid battery capacity of 190 Ah

4. Inverter 600W and 100W modified sine wave

The scheme works budget avtonomki looks like:

Note that the inverter is directly connected to the battery, even if it uses the entire capacity of solar batteries. In addition, it is necessary to avoid power failure when connected solar cells, because it threatens the failure of the controller.

The first year of my solar avtonomka existed in this form and allows you to charge gadgets, the evening was light and bright sunny days to operate the power, such as a drill or jigsaw.

Material received more than expected, so the second version of the solar avtonomki, which cost a little more, but allows you to use a powerful electric tools, use a pumping station, and opt for the summer of gasoline generator, I will describe in the next article. What distinguishes the good china from China Europe? Should I buy expensive equipment through Ebay? And I will give the answer to the main question: was it worth it? Please ask specifying questions to which I will answer in the next section.

Source: habrahabr.ru/post/251449/

Since solar panels are the most visible part of the system, and even convert the sun's energy into electricity, then it should start with them. There are two ways to obtain the solar cell: do it yourself or buy ready-made. I must say that the total cost of the final product in the manufacture of several panels and without experience will cost about the same amount as the final panel of the same capacity, but produced at the plant. But it is interesting to do.

Here we must again add a little theory. There are three available to customers for sane money, technology solar cells composed of different cells: monocrystalline, polycrystalline and amorphous silicon. They differ in structure and can even see it in the eyes. I will try to explain as simply as possible, and those wishing to experience the difference in chemical compositions can view the information for yourself - do not overload the article.

Amorphous silicon - the most promising technology for manufacturing. Allows to make bendable panel and supply current when the scattered light that is in cloudy weather, but quickly degraded, resulting in a decrease in efficiency.

Single crystal - pure silicon cells from the primary. As a rule, black plate without inclusions, almost square shape with rounded edges. Sometimes sawn in half to increase the voltage line elements.

Polycrystalline - silicon cells from secondary or not very clean. Probably used scrap of a single crystal.

Types of batteries are arranged in descending order of value. And if the second and third options are still close, the first noticeable breaks in the cost of, and eventually reduces the production of energy. To manufacture its own solar panels (the joint venture or SB - Solar Battery) in China was commissioned party solar cells Class Grade B (read about the classification of elements can HERE ) number for a couple of the Security Council. You need to check that the set includes terminal boxes, bus for connecting the cells to each other and at least a couple of meters of cable. There were also ordered MC4 connectors for connecting batteries. In Russia, was commissioned by the enlightened manufacturing toughened glass 4 mm thick. This thickness is due to the need to protect themselves from any icicles (hail) and other weather conditions (focused with a stone unlikely to survive), and enlightened glass need to increase the efficiency of elements. For framing glass, protection from chips and ease of installation was purchased aluminum corner 30x30 and necessary hardware to it. To connect the solar system was chosen stranded copper cable with a cross section of 6 mm square. To charge was booked in the same China Controller PWM, and for power supply 220V - simple car inverter power of 100 watts Chinese. Later I will explain the difference between conventional and Chinese Watts.

The energy system №1. Budget

Self-production of solar panel

Thus, the assembly. Modules come in a box and some of them were broken, as in the first photograph. To this end, the stock usually has about 10 pieces. I complained in a letter to the Chinese, and he sent me a free 10 more cells. Each cell gave 0, 5 and 4 A statement by Chinese merchants. That is, each module 2 watts. To charge the battery must have the voltage is above 14 volts 4, that is, it is necessary to merge cells in series. Looking at the factory panels and using the practice of many Homebrew, it was decided to combine the two in one glass chain for 36 elements to give 18 volts and 8A peak. That is one panel could bring up to 144 watts of power, which has never happened. Causes look at later, but for now manufacturing.

The procedure is simple. Solder shank:

Cooking glass with frame:

Puts solder, bus terminals and solder wires, and then pour a special compound to seal all the plates. People poured sealant, various mastics, I liked ready compound manufacturing company in St. Petersburg. It's nice that Russian production, so give money was not sorry, and the result is pleasantly pleased. The conclusions of the contacts would be good to priladit sealed box with a diode that will prevent a drop in the power system is connected in series, if one of the batteries will be darkened. The box came with cells.

As a result, I got two solar panels with a rated output of 288 Вт.

But then there are lots of conventions. When heated, the efficiency of the solar panel it even decreases the calculated percent 20. Moreover, influences nepropay elements and microcracks, which inevitably arise during soldering. As a result of measurement in the summer sun I got a 40 watt each panel, that is, the result is three times smaller than expected. The price of this panel came around 6000-6500 rubles, while the factory panel treated with delivery in 7000-7500 rubles. So I finished the initiative to continue to buy only original panel.

Selecting a base voltage

Perhaps this is one of the first decisions that must be taken in the design of solar panels. The fact that the systems are solar-powered with a voltage that is a multiple of 12 - in fact, most batteries have just such a strain. Even battery-capacity collected from cells at 2B is often collected at 12, 24, 36 or 48 volts. You've got to remember physics and electrical power formula: P = U * I. From this it follows that the same power, increasing the voltage, we will reduce the current. Quite naturally, the decrease in the current would entail reducing the load on the element base and reduced wire sizes, but also infinitely increase the voltage can not be. Then there is the following problem: DC, unlike AC voltage increases above 36 volts is far more dangerous to humans. If you do not delve into the theory, the AC voltage to 220V hand tear often possible, but the constant is almost never. In addition to this low voltage can vote, if only because that 12V - a typical car battery voltage, which means there are many different techniques designed for this voltage. In addition, the capacity of the storage capacity can be easily added in parallel to conventional batteries, while a higher voltage would have to buy batteries in pairs, threes or fours. There is another unpleasant moment in the series connection of batteries: imbalance of cells, which leads to the failure of the first one cell, then the whole of the battery and the entire chain, if time does not track down the problem.

My choice: 12

Selecting a charge controller solar powered

There are two basic types of controllers: PWM or PWM controller and MPPT or Maximum Power Point Tracking - Tracking the maximum power point.

The first type is as simple and familiar with PWM no need to explain, but for the rest of the most simple: to achieve the maximum level of the battery, the controller issues a ripple current to the battery, not letting recharge. Plus this scheme: simplicity, and therefore, low cost. Minus: You can connect the battery nominal voltage of which coincides with the nominal value of the battery voltage.

MPPT controllers are difficult, expensive, but have a great advantage: the solar batteries can be connected in series, thereby increasing the tension in the chain to the controller, and reducing the current, which allows the use of thinner wires and reduce losses in energy transmission to the controller. And the efficiency of such controllers is higher because they are scanned at regular intervals currents at different voltages and choose a point of maximum power. Hence the name. Those who wish to plunge into the world of technology, you can go here , where quite sensibly and detail painted.

By its own panels I bought Chinese PWM-controller, giving charge to 30A, ie 360 W at 12 V or 720 watts at 24V. But because the system is selected to 12V, the limit - it is 30A or 3 solar panels are connected in parallel.

Add to it ordered from the same voltmeter and ammeter to see the condition of the battery and a charge enters the battery. The battery has been chosen the cheapest lead acid, with a capacity of 190 Ah, because I still believed that I was about to be connected electricity network.

Select the inverter

Turn to the most entertaining point of our system. Let's start with the fact that the inverters, in addition to power, easily divided into two types: with pure sine wave output and a modified sine wave (also referred approximated sine wave or square wave). The first issue pure sine wave, while the latter have a step on the chart:

For most equipment is no difference, and if you connect a simple voltmeter, his testimony will be about the same. But if you compare the prices of both types of devices of the same power, it turns out that the price is different order of magnitude. Do I have to pay for a pure sine and what is it for? B> As shown, most devices are easy to get along with a modified sine wave, although some engines, such as compressors, refrigerators, start to warm up more and increases the risk of premature system. In addition, if you connect to a modified sine wave audio equipment, you will hear a rattling noise, which is not happy, when you want to enjoy a good sound. From my own experience I can say that from a modified sine wave refused to work only washing machine - all other devices worked successfully. If there is a good amount for the inverter, you should choose pure sine if other devices are sensitive to the purity of the signal.

We select the inverter capacity

In this regard, a lot of nuances that affect the choice of the inverter. The rule is: the whole is summed planned load power and multiplied by two. For example: 4 lamps of 60 watts + 800 watts washing machine + laptop + 80 watts 100 watts + Refrigerator TV 50 watts. It would seem that the maximum power consumption is 240 + 800 + 80 + 100 + 50 = 1270 watt inverter and enough to take on the 1300-1500 watts, but! Various load behave differently. For example, the starting current can be up to ten times cooler values during the launch, which means it will require 1 kW of power immediately, and if at that time will be included light and washing machine, the inverter simply fall into the error, if you do not burn. In addition, Chinese inverters такого type 1500 W were unable to run the refrigerator with a rated power of 100 W power consumption. Experiment was carried out when the refrigerator started from the generator, and then quickly switched to the inverter with the switch phases. So was able to feed from the Chinese refrigerator inverter 600W - barbarism, it is difficult, but it works. The trouble is one thing a second time to launch such an inverter refrigerator not. Cheating was whether to put a refrigerator setting the maximum frost. And fridge freezes up until you turn it off. So it is possible for the light day namorozit products, and at night to disable it.

Thus, the capacity of the inverter must be such as to ensure a two-time reserve your consumption of conventional instruments or ten times to start the engine.

My choice: two Chinese inverter capacity of 1,000 and 600 watts.

Duplicate

When choosing a cheap and simple accessories it is better to be put on back-up systems. This will not remain without electricity in the event of failure of any element. Such reassurance would not be expensive, but will provide peace of mind and a stable power supply.

In general, the first set avtonomki looked like:

1. Two homemade solar panels with a total capacity of 80 W

2. PWM- Charge controller with maximum current up to 30A

3. automobile lead-acid battery capacity of 190 Ah

4. Inverter 600W and 100W modified sine wave

The scheme works budget avtonomki looks like:

Note that the inverter is directly connected to the battery, even if it uses the entire capacity of solar batteries. In addition, it is necessary to avoid power failure when connected solar cells, because it threatens the failure of the controller.

The first year of my solar avtonomka existed in this form and allows you to charge gadgets, the evening was light and bright sunny days to operate the power, such as a drill or jigsaw.

Material received more than expected, so the second version of the solar avtonomki, which cost a little more, but allows you to use a powerful electric tools, use a pumping station, and opt for the summer of gasoline generator, I will describe in the next article. What distinguishes the good china from China Europe? Should I buy expensive equipment through Ebay? And I will give the answer to the main question: was it worth it? Please ask specifying questions to which I will answer in the next section.

Source: habrahabr.ru/post/251449/