969

BAPV AND BIPV solar panels: what's the difference?

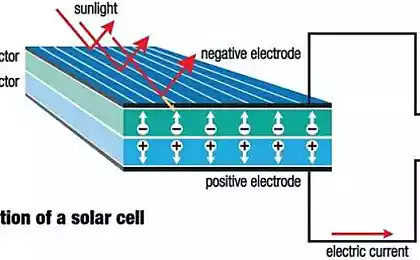

The main function of photovoltaic modules (or PV modules) is the conversion of sunlight into electric current. The output of the PV module generates DC current that can be used directly or to accumulate in batteries for later use.

In the 70-80-ies of XX century the idea was to transform buildings and urban buildings from consumers of energy in generation plant with installation of photovoltaic modules or simply solar panels. It is difficult to say who first proposed this idea, but perhaps the most important role in its promotion has played a Swiss engineer Marcus real (Markus G. Real ). In 1986, he undertook an ambitious project to install 1 MW of solar panels. Phoned 333 Zurich landlord, he persuaded them to install solar panels on the roofs of their houses. Thus was born the idea of decentralized generation and energy storage, i.e., in fact, what is now called "smart electricity grids" (Smart Grid).

Almost simultaneously there arose a need to develop different ways of integrating PV modules into the design of the building, as the discussions about the violation of aesthetics and architectural integrity of the buildings became a new obstacle to the popularization of this idea.

So, along with the usual installation of photovoltaic modules to generate electricity, were two new concepts in architecture, describes the two main approaches in the integration of solar panels into the design of buildings:

BAPV (Building Applied Photovoltaics) — addition of PV modules on top of the building envelope (facade or roof)

BIPV (Building Integrated Photovoltaics) — replacement part (or full) building envelope was specially created for the project photovoltaic modules.

It is interesting to note that, in addition to the above decryption abbreviation BAPV, in the literature there are other options:

"bilding addobed photovoltaics" — "adapted to the building of photovoltaic modules"

"building attached photovoltaics" – "attached to the building of photovoltaic modules",

that, fortunately, does not change neither the acronym or its meaning. In General, the confusion and ambiguity of terms in the literature on integrated photovoltaic modules is currently quite common. We can say that sustainable terminology has not yet developed in this nascent, section architecture. In Russian literature the terminology is not systematized because of the practical lack of it on the subject.

Hand in the writing of this article, the author pursued, including a goal to bring a certain clarity in the terminology. Summarizing the above we can conclude that the photovoltaic modules can be simply installed on the outer shell of the building (see figure 1), or can be integrated into its architectural concept (figure 2).

Integration of photovoltaic modules can be achieved in two different ways— BAPV and BIPV. In this article we will consider only integrated into the architecture of the building PV modules.

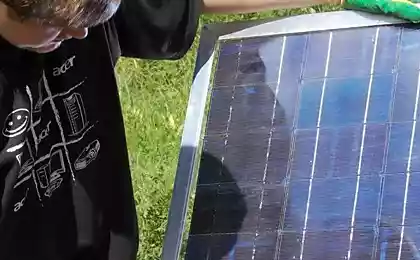

Figure 1: Solar panels installed on the roof of the building, but not integrated into its architecture (BAPV)

Figure 2: PV modules are organically integrated into the building's architecture (BIPV)

As a rule, in the case of installation of photovoltaic modules on top of the existing roof (figure 1) using the standard modules with corresponding mounts, while in the case of integration, to panels and fixtures can meet certain design and technical limitations. Development of various types of mounts for the integration of solar panels has become a separate industry, and every year, manufacturers offer us new and new systems of fixing for different types of facades and roofs.

To BAPV modules usually do not impose any special requirements in addition to aesthetic appeal because they do not incur any additional functions, and their main task is the efficient conversion of solar energy into electrical energy. In the case of BIPV, the photovoltaic modules replace part of the external shell of the building and should have all functions of model design. Thus, it is clear that BIPV modules must meet many more requirements.

Currently, the European Committee for electrotechnical standardization (CENELEC) is responsible for European standards for Electrotechnology, has launched a project to develop a unified standard for PV modules BIPV and BAPV (prEN 50583 Photovoltaics in buildings). The lack of this standard is now one of the limiting reasons for the development of the BIPV sector, as currently, all BIPV modules are checked for compliance to multiple standards. The other constraining reason, of course, are slightly higher prices on BIPV modules in comparison with conventional photovoltaic modules.

In fact, these two reasons led to the bankruptcy of a number of BIPV — oriented producers of photovoltaic modules. Along with their bankruptcy disappeared from the market some of them varieties developed by the PV modules. For example, at the present time practically not produced of flexible thin film modules, which were high expectations in terms of their use in architectural projects using photovoltaics.

Active participation in the development of a European standard takes prEN50583 research group Task 41 Solar Energy&Architecture International energy Agency solar heating and air conditioning." IEA SHC (International Energy Agency Solar Heating and Cooling Programme). 41 Task group proposed the following categories of integration of photovoltaic modules in the architecture (as BIPV and BAPV):

1. the addition of photovoltaic modules;

2. add dual function;

3. free standing design;

4. part of the surface of the cladding;

5. all the facade of the building;

6. the form of the building is optimized for maximum collection of solar energy;

7. other (1-6).

As we have noted, in the case of a BAPV PV modules, generally regarded as more devices added to the building envelope, even if they are seamlessly integrated into the architectural concept. In the case of BIPV, the photovoltaic modules are building components and materials, and an integral part of the design of the building, and at the same time, part of the General architectural image of the building. Some have already implemented projects using BIPV modules are considered innovative. In other words, BIPV is an innovative sector of the construction industry and it requires the joint creative work of architects, planners, designers, engineers and manufacturers of photovoltaic modules.

The result of this cooperation should be not only providing an optimal collection of solar energy but also achieving the required physical and technical characteristics of frame structures with embedded photovoltaic modules: thermal conductivity, sound insulation, waterproofing, mechanical strength, etc.

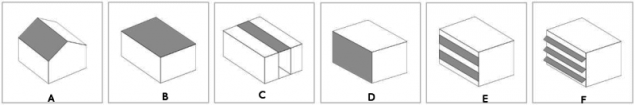

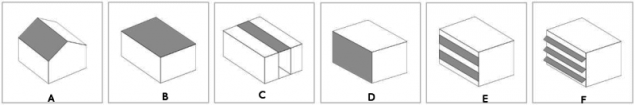

For introduction to the building envelope of photovoltaic modules, the research team Task 41 suggested the following process categories shown in Figure 4.

Figure 4: Categories of integrated modules BAPV, BIPV. A — pitched roof, B — flat roof, C — skylight (lantern) D — front facing, E — facade glazing, F — external device.

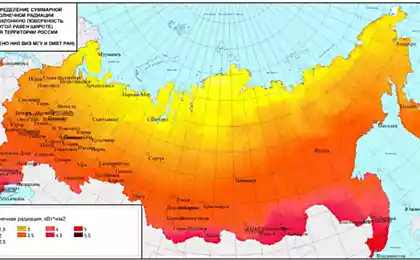

Solar modules differ from the traditional materials because of its primary function — they produce electricity. It is therefore reasonable to initially provide their location in the concept design of the building, considering all the features of sunlight, dictated by the geographical latitude of the location and proximity of neighboring buildings, relief and so on, including in the project of building integrated solar modules, it is necessary not only simply fit in with the facade or roofing solution, but be sure to consider the location and orientation of the modules relative to the sun. Any successful project is the result of a compromise between these two approaches.

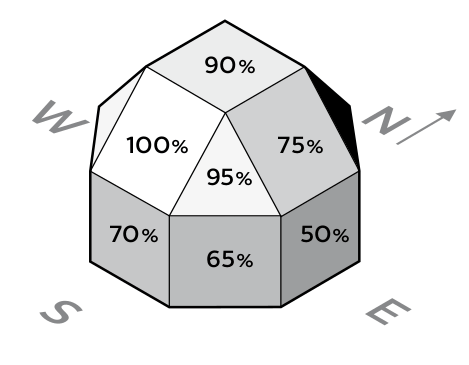

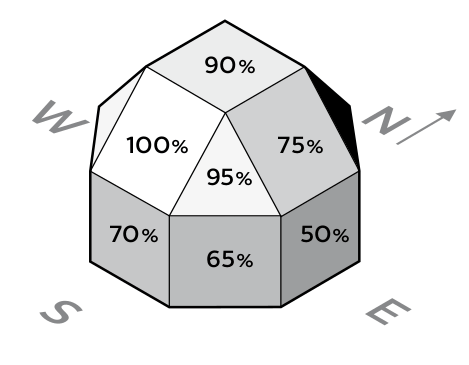

Number falling on the building surface solar radiation depends on the orientation of the surface and from geographic latitude. Optimum angle of inclination to the horizon is close to the latitude and is directed straight to the South, for example for Moscow 38° to the horizon. Small deviations from the optimal tilt angle and direction only lead to small losses in the formulation. For example, for the latitude of Moscow can be considered an optimum tilt angle ranging from 25° to 45°. If you take the best angle and direction for 100% output from the other surfaces of the building looks as shown in Figure 5.

Figure 5: electricity Generation depending on the orientation of the surface

Varieties of photovoltaic modules

Photovoltaic modules differ from each other in composition and production technology that has a direct impact on their design and, ultimately, on the architecture of the building. The vast majority of currently produced solar modules based on silicon. This is because silicon is quite common in nature chemical element.

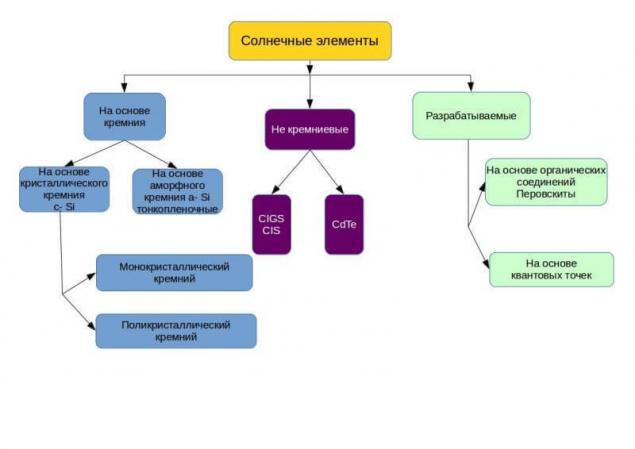

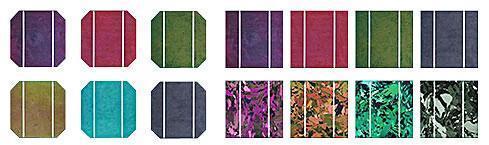

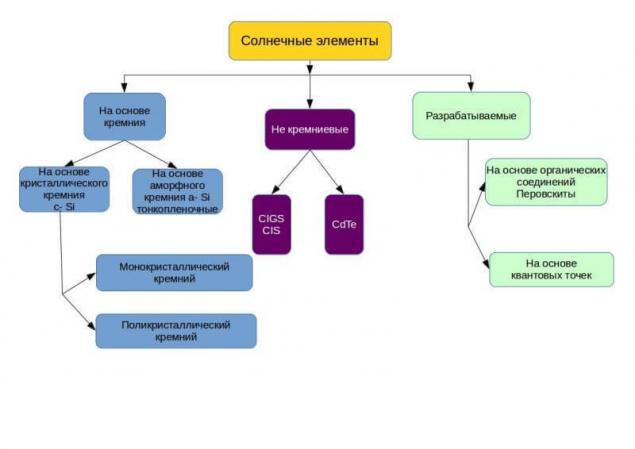

The principle of operation of photovoltaic modules is not the subject of this article, but knowledge of varieties and distinctive features is essential for architects and designers. Below (see figure 6), schematically shows the main varieties of modern photovoltaic modules, separated according to their chemical composition. Here we give a brief description of the appearance of these modules, leaving aside the characteristics of the other physical characteristics, as the appearance of the panels is important to their successful integration into the architecture of the building.

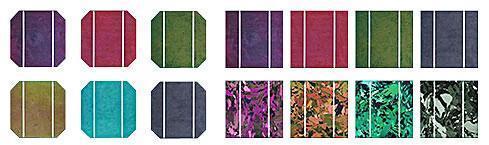

Figure 6: Schematic representation of the varieties of solar modules.

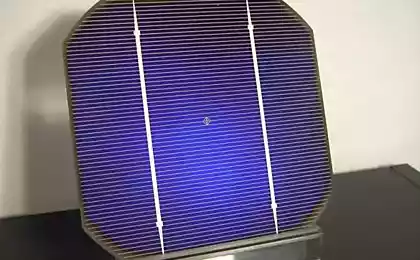

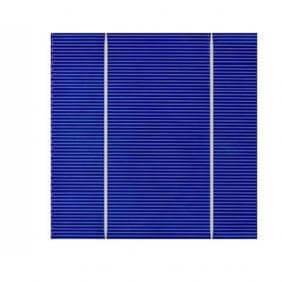

Monocrystalline and polycrystalline panels are composed of cells. Monocrystalline cells generally have the shape of a "convex" square (see figure 7). This is due to the fact that the cells are cut from a single crystal of cylindrical shape. Polycrystalline cell have the shape of a rectangle or square because they are cut from "less pure" of a crystal having the form of a parallelepiped.

Figure 7: Monocrystalline cell.

Figure 7: the Polycrystalline cell.

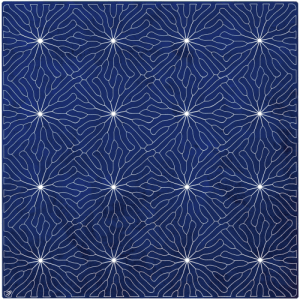

Both types of cells may have a surface of different colors, and the polycrystalline another, and not only homogeneous, but also the structure in the form of frost patterns (figure 8).

Figure 8: single crystal (left)and polycrystalline (right) BIPV — cells. Polycrystalline cells can be structured in the form of frost patterns

Thin-film solar panels based on amorphous silicon a-Si, CIGS (cuprum-irridium-galium-selenide) or CaTe (cadmium-teluride), have a homogeneous structure over the entire surface of the module and are the result of completely different production technology. They are also of great interest from an architectural point of view, providing to the architect many possibilities for you to design different texture, texture, color and degree of transparency and is ideal for facade solutions.

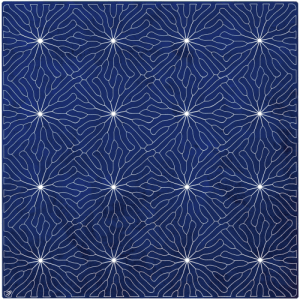

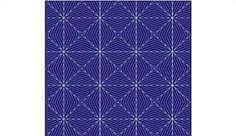

The outer layer integrated photovoltaic module also functions as a finishing material for the outer shell of the building, so the manufacturers strive to create attractive from an aesthetic point of view, the design of the outer surface of the modules, developing new production technology (figure 9).

Figure 9. These photos show an innovative solar modules with back contact arrangement and with the original patterns on the outer surface

Attractive quality of solar modules is the fact that solar panels reflect the environment as mirror glass. Reflection there are different effects: distorted on a matte surface or glossy clear surface. In some cases, the reflection may be vague or subtle. All of these conditions can be included in the architectural concept.

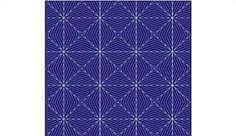

For translucent facades and atriums fit semitransparent PV modules. They can be both crystalline and thin-film. Semitransparent crystalline modules represent two transparent glass layers between which some intervals are placed photovoltaic silicon cells (see figure 10).

The transparency of such modules is determined by the width of the spaces between the cells. The same thin-film modules uniform throughout the area with varying degrees of transparency.

This type of glazing is used for shading the interior space. The undisputed world leader in the manufacture of translucent photovoltaic glass is a Spanish company Onyx Solar.

Figure 10: Translucent solar panel based on crystalline cells

Figure 10: Option of translucent panels are produced in thin-film technology. published

P. S. And remember, only by changing their consumption — together we change the world! © Join us at Facebook , Vkontakte, Odnoklassniki

Source: green-city.su/bapv-i-bipv-solnechnye-paneli-v-chyom-raznica/

In the 70-80-ies of XX century the idea was to transform buildings and urban buildings from consumers of energy in generation plant with installation of photovoltaic modules or simply solar panels. It is difficult to say who first proposed this idea, but perhaps the most important role in its promotion has played a Swiss engineer Marcus real (Markus G. Real ). In 1986, he undertook an ambitious project to install 1 MW of solar panels. Phoned 333 Zurich landlord, he persuaded them to install solar panels on the roofs of their houses. Thus was born the idea of decentralized generation and energy storage, i.e., in fact, what is now called "smart electricity grids" (Smart Grid).

Almost simultaneously there arose a need to develop different ways of integrating PV modules into the design of the building, as the discussions about the violation of aesthetics and architectural integrity of the buildings became a new obstacle to the popularization of this idea.

So, along with the usual installation of photovoltaic modules to generate electricity, were two new concepts in architecture, describes the two main approaches in the integration of solar panels into the design of buildings:

BAPV (Building Applied Photovoltaics) — addition of PV modules on top of the building envelope (facade or roof)

BIPV (Building Integrated Photovoltaics) — replacement part (or full) building envelope was specially created for the project photovoltaic modules.

It is interesting to note that, in addition to the above decryption abbreviation BAPV, in the literature there are other options:

"bilding addobed photovoltaics" — "adapted to the building of photovoltaic modules"

"building attached photovoltaics" – "attached to the building of photovoltaic modules",

that, fortunately, does not change neither the acronym or its meaning. In General, the confusion and ambiguity of terms in the literature on integrated photovoltaic modules is currently quite common. We can say that sustainable terminology has not yet developed in this nascent, section architecture. In Russian literature the terminology is not systematized because of the practical lack of it on the subject.

Hand in the writing of this article, the author pursued, including a goal to bring a certain clarity in the terminology. Summarizing the above we can conclude that the photovoltaic modules can be simply installed on the outer shell of the building (see figure 1), or can be integrated into its architectural concept (figure 2).

Integration of photovoltaic modules can be achieved in two different ways— BAPV and BIPV. In this article we will consider only integrated into the architecture of the building PV modules.

Figure 1: Solar panels installed on the roof of the building, but not integrated into its architecture (BAPV)

Figure 2: PV modules are organically integrated into the building's architecture (BIPV)

As a rule, in the case of installation of photovoltaic modules on top of the existing roof (figure 1) using the standard modules with corresponding mounts, while in the case of integration, to panels and fixtures can meet certain design and technical limitations. Development of various types of mounts for the integration of solar panels has become a separate industry, and every year, manufacturers offer us new and new systems of fixing for different types of facades and roofs.

To BAPV modules usually do not impose any special requirements in addition to aesthetic appeal because they do not incur any additional functions, and their main task is the efficient conversion of solar energy into electrical energy. In the case of BIPV, the photovoltaic modules replace part of the external shell of the building and should have all functions of model design. Thus, it is clear that BIPV modules must meet many more requirements.

Currently, the European Committee for electrotechnical standardization (CENELEC) is responsible for European standards for Electrotechnology, has launched a project to develop a unified standard for PV modules BIPV and BAPV (prEN 50583 Photovoltaics in buildings). The lack of this standard is now one of the limiting reasons for the development of the BIPV sector, as currently, all BIPV modules are checked for compliance to multiple standards. The other constraining reason, of course, are slightly higher prices on BIPV modules in comparison with conventional photovoltaic modules.

In fact, these two reasons led to the bankruptcy of a number of BIPV — oriented producers of photovoltaic modules. Along with their bankruptcy disappeared from the market some of them varieties developed by the PV modules. For example, at the present time practically not produced of flexible thin film modules, which were high expectations in terms of their use in architectural projects using photovoltaics.

Active participation in the development of a European standard takes prEN50583 research group Task 41 Solar Energy&Architecture International energy Agency solar heating and air conditioning." IEA SHC (International Energy Agency Solar Heating and Cooling Programme). 41 Task group proposed the following categories of integration of photovoltaic modules in the architecture (as BIPV and BAPV):

1. the addition of photovoltaic modules;

2. add dual function;

3. free standing design;

4. part of the surface of the cladding;

5. all the facade of the building;

6. the form of the building is optimized for maximum collection of solar energy;

7. other (1-6).

As we have noted, in the case of a BAPV PV modules, generally regarded as more devices added to the building envelope, even if they are seamlessly integrated into the architectural concept. In the case of BIPV, the photovoltaic modules are building components and materials, and an integral part of the design of the building, and at the same time, part of the General architectural image of the building. Some have already implemented projects using BIPV modules are considered innovative. In other words, BIPV is an innovative sector of the construction industry and it requires the joint creative work of architects, planners, designers, engineers and manufacturers of photovoltaic modules.

The result of this cooperation should be not only providing an optimal collection of solar energy but also achieving the required physical and technical characteristics of frame structures with embedded photovoltaic modules: thermal conductivity, sound insulation, waterproofing, mechanical strength, etc.

For introduction to the building envelope of photovoltaic modules, the research team Task 41 suggested the following process categories shown in Figure 4.

Figure 4: Categories of integrated modules BAPV, BIPV. A — pitched roof, B — flat roof, C — skylight (lantern) D — front facing, E — facade glazing, F — external device.

Solar modules differ from the traditional materials because of its primary function — they produce electricity. It is therefore reasonable to initially provide their location in the concept design of the building, considering all the features of sunlight, dictated by the geographical latitude of the location and proximity of neighboring buildings, relief and so on, including in the project of building integrated solar modules, it is necessary not only simply fit in with the facade or roofing solution, but be sure to consider the location and orientation of the modules relative to the sun. Any successful project is the result of a compromise between these two approaches.

Number falling on the building surface solar radiation depends on the orientation of the surface and from geographic latitude. Optimum angle of inclination to the horizon is close to the latitude and is directed straight to the South, for example for Moscow 38° to the horizon. Small deviations from the optimal tilt angle and direction only lead to small losses in the formulation. For example, for the latitude of Moscow can be considered an optimum tilt angle ranging from 25° to 45°. If you take the best angle and direction for 100% output from the other surfaces of the building looks as shown in Figure 5.

Figure 5: electricity Generation depending on the orientation of the surface

Varieties of photovoltaic modules

Photovoltaic modules differ from each other in composition and production technology that has a direct impact on their design and, ultimately, on the architecture of the building. The vast majority of currently produced solar modules based on silicon. This is because silicon is quite common in nature chemical element.

The principle of operation of photovoltaic modules is not the subject of this article, but knowledge of varieties and distinctive features is essential for architects and designers. Below (see figure 6), schematically shows the main varieties of modern photovoltaic modules, separated according to their chemical composition. Here we give a brief description of the appearance of these modules, leaving aside the characteristics of the other physical characteristics, as the appearance of the panels is important to their successful integration into the architecture of the building.

Figure 6: Schematic representation of the varieties of solar modules.

Monocrystalline and polycrystalline panels are composed of cells. Monocrystalline cells generally have the shape of a "convex" square (see figure 7). This is due to the fact that the cells are cut from a single crystal of cylindrical shape. Polycrystalline cell have the shape of a rectangle or square because they are cut from "less pure" of a crystal having the form of a parallelepiped.

Figure 7: Monocrystalline cell.

Figure 7: the Polycrystalline cell.

Both types of cells may have a surface of different colors, and the polycrystalline another, and not only homogeneous, but also the structure in the form of frost patterns (figure 8).

Figure 8: single crystal (left)and polycrystalline (right) BIPV — cells. Polycrystalline cells can be structured in the form of frost patterns

Thin-film solar panels based on amorphous silicon a-Si, CIGS (cuprum-irridium-galium-selenide) or CaTe (cadmium-teluride), have a homogeneous structure over the entire surface of the module and are the result of completely different production technology. They are also of great interest from an architectural point of view, providing to the architect many possibilities for you to design different texture, texture, color and degree of transparency and is ideal for facade solutions.

The outer layer integrated photovoltaic module also functions as a finishing material for the outer shell of the building, so the manufacturers strive to create attractive from an aesthetic point of view, the design of the outer surface of the modules, developing new production technology (figure 9).

Figure 9. These photos show an innovative solar modules with back contact arrangement and with the original patterns on the outer surface

Attractive quality of solar modules is the fact that solar panels reflect the environment as mirror glass. Reflection there are different effects: distorted on a matte surface or glossy clear surface. In some cases, the reflection may be vague or subtle. All of these conditions can be included in the architectural concept.

For translucent facades and atriums fit semitransparent PV modules. They can be both crystalline and thin-film. Semitransparent crystalline modules represent two transparent glass layers between which some intervals are placed photovoltaic silicon cells (see figure 10).

The transparency of such modules is determined by the width of the spaces between the cells. The same thin-film modules uniform throughout the area with varying degrees of transparency.

This type of glazing is used for shading the interior space. The undisputed world leader in the manufacture of translucent photovoltaic glass is a Spanish company Onyx Solar.

Figure 10: Translucent solar panel based on crystalline cells

Figure 10: Option of translucent panels are produced in thin-film technology. published

P. S. And remember, only by changing their consumption — together we change the world! © Join us at Facebook , Vkontakte, Odnoklassniki

Source: green-city.su/bapv-i-bipv-solnechnye-paneli-v-chyom-raznica/