582

Solar panels in the form of a self-adhesive film

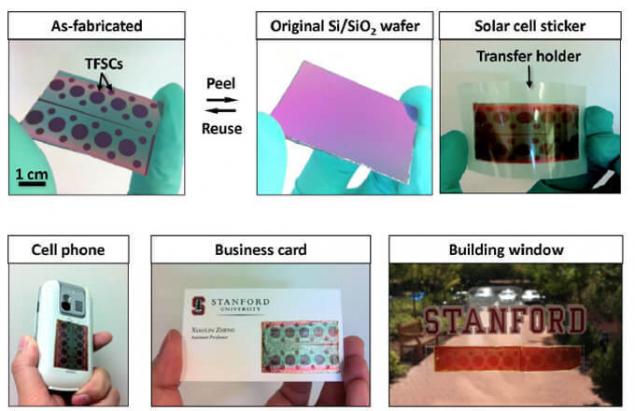

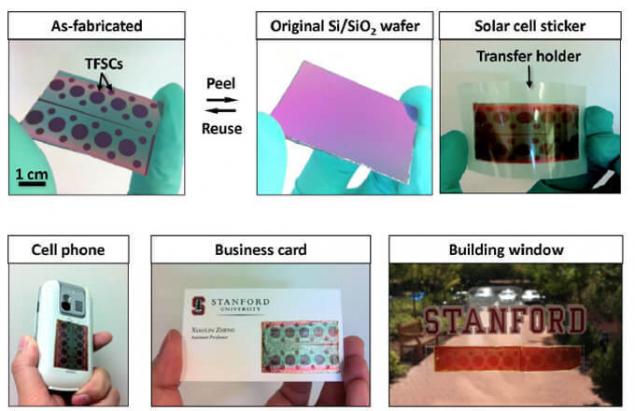

Association of thin-film electronics with the new solar panels will provide opportunities for the creation of new technical devices, and this is only the first stage in the development of this technology. Technology "rip and stick" can be used absolutely versatile, I'm sure the head of the team of physicists at Stanford University Xiaolin Zheng.

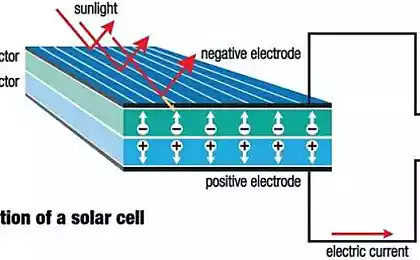

Jeong with like-minded developed and reproduced these solar panels all over the globe, resulting from experiments with films of silicon oxide and Nickel nanometer thickness. Scientists explain that traditionally, solar panels can work normally only on very smooth surfaces, in particular substrates, e.g. of glass or silicon.

The problem is that if you use other substrate, they will not fit due to poor surface flatness and low resistance to high temperatures and chemical processing. This tradition is very limiting of the scope of application of solar power supply with a simultaneous increase in their cost.

SUBSCRIBE to OUR youtube channel that allows you to watch online, download from YouTube free video about the recovery, the rejuvenation of man. Love for others and ourselves, as the feeling of high vibrations — an important factor for improvement .

Put LIKES and share with your FRIENDS!

www.youtube.com/channel/UCXd71u0w04qcwk32c8kY2BA/videos

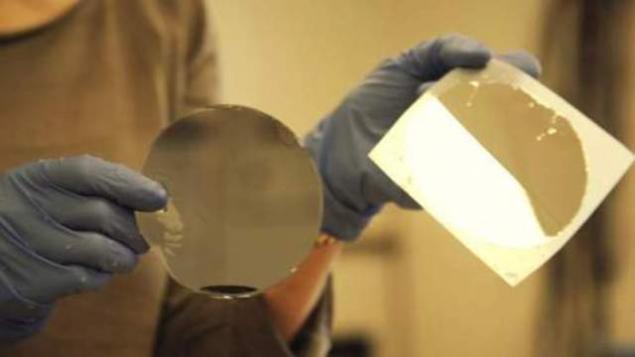

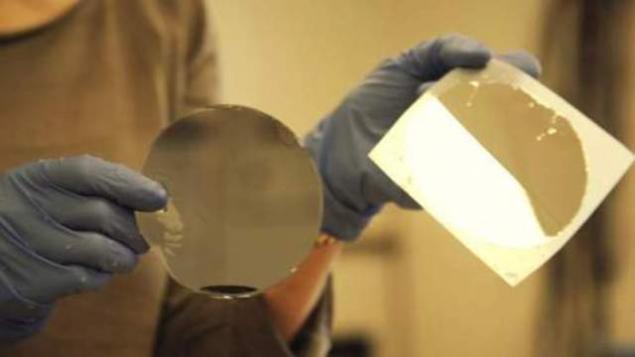

The developers managed to get rid of these flaws in their thin-film batteries thanks to the original approach. The main idea is to separate the battery from the finished silicon wafer, then it would be possible to use any substrate, regardless of its flatness and rigidity.

The decision of the scientists gave the technology of producing graphene, its discoverers Geim and Novoselov. By a similar method Xiaolin Zheng and his colleagues applied a thin film of Nickel (300 nm) on a plate of a mixture of silicon oxide and pure silicon by electron beam evaporation.

The next step on the obtained two-layer structure caused the active part of thin film solar battery and a protective polymer layer to prevent contact of the active part of water. Then to one edge stuck thermostat, and put the plate in a water bath at room temperature.

A few minutes later, the scientists separated the edge of the tape so water molecules infiltrated between the Nickel plate, then raising the bar thermococci, physics have completely separated all the film received solar panels from silicon wafers. At the stage of complete separation of film scholars pre-heated the entire structure to 90 degrees to weaken the adhesion.

After separation from the plate, the film may be pasted onto the target surface with glue, and the plate can be used again for the formation of the following battery labels.

It is important to note that the obtained film-type solar arrays show almost identical efficiency before and after the separation of the film from the substrate. The measurements showed that the current and voltage before and after the process of plywood on a sheet of stainless steel or sodium-calcium glass are indistinguishable, it is implied that no damage occurs during the transfer stickers on any surface.

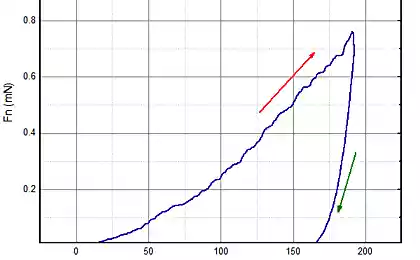

The average measurement of performance metrics over 20 solar panels with an area of 0.05 sq cm and 0.28 cm, respectively, showed an efficiency of 7.4 ± 0.5% and 5,2 ± 0,1% to process plywood and an efficiency of 7.6 ± 0.5% and p = 5,3 ± 0,1% after plywood. The difference of efficiency of elements of different sizes due to the large resistance of series-connected batteries.

However, more important is the fact that both solar panels are almost identical to the performance indicators before and after the process of plywood, and the deviation is only 5%, which is within measurement error. These results illustrate several key advantages of this technology: versatility in substrate choices, high quality of the original performance, simplicity and scalability of the technological process, as well as additional savings on original reusable silicon substrates.

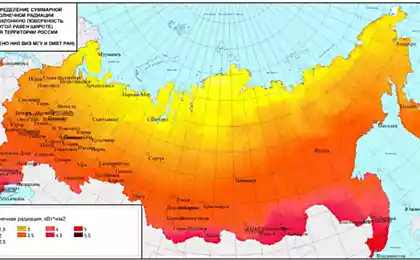

Zheng argues that such film solar battery can be sticked on any surface, on glass, on fabric, on paper, or on any other unusual for photoelectronic material, even on the walls of houses. And in each case, the battery will generate the same amount of electricity as traditional solar panels of the previous technology, while maintaining the effectiveness of 7.5%.

Plus, the battery sticker is easy to bend and it does not damage or reduce the effectiveness. Scientists anticipate that this is a wonderful property at a low cost will allow a new solar battery — stickers as power sources for smart wear and other electronic devices, where flexibility is important. published

Source: elektrovesti.net/48146_solnechnye-batarei-v-vide-samokleyashcheysya-plenki

Jeong with like-minded developed and reproduced these solar panels all over the globe, resulting from experiments with films of silicon oxide and Nickel nanometer thickness. Scientists explain that traditionally, solar panels can work normally only on very smooth surfaces, in particular substrates, e.g. of glass or silicon.

The problem is that if you use other substrate, they will not fit due to poor surface flatness and low resistance to high temperatures and chemical processing. This tradition is very limiting of the scope of application of solar power supply with a simultaneous increase in their cost.

SUBSCRIBE to OUR youtube channel that allows you to watch online, download from YouTube free video about the recovery, the rejuvenation of man. Love for others and ourselves, as the feeling of high vibrations — an important factor for improvement .

Put LIKES and share with your FRIENDS!

www.youtube.com/channel/UCXd71u0w04qcwk32c8kY2BA/videos

The developers managed to get rid of these flaws in their thin-film batteries thanks to the original approach. The main idea is to separate the battery from the finished silicon wafer, then it would be possible to use any substrate, regardless of its flatness and rigidity.

The decision of the scientists gave the technology of producing graphene, its discoverers Geim and Novoselov. By a similar method Xiaolin Zheng and his colleagues applied a thin film of Nickel (300 nm) on a plate of a mixture of silicon oxide and pure silicon by electron beam evaporation.

The next step on the obtained two-layer structure caused the active part of thin film solar battery and a protective polymer layer to prevent contact of the active part of water. Then to one edge stuck thermostat, and put the plate in a water bath at room temperature.

A few minutes later, the scientists separated the edge of the tape so water molecules infiltrated between the Nickel plate, then raising the bar thermococci, physics have completely separated all the film received solar panels from silicon wafers. At the stage of complete separation of film scholars pre-heated the entire structure to 90 degrees to weaken the adhesion.

After separation from the plate, the film may be pasted onto the target surface with glue, and the plate can be used again for the formation of the following battery labels.

It is important to note that the obtained film-type solar arrays show almost identical efficiency before and after the separation of the film from the substrate. The measurements showed that the current and voltage before and after the process of plywood on a sheet of stainless steel or sodium-calcium glass are indistinguishable, it is implied that no damage occurs during the transfer stickers on any surface.

The average measurement of performance metrics over 20 solar panels with an area of 0.05 sq cm and 0.28 cm, respectively, showed an efficiency of 7.4 ± 0.5% and 5,2 ± 0,1% to process plywood and an efficiency of 7.6 ± 0.5% and p = 5,3 ± 0,1% after plywood. The difference of efficiency of elements of different sizes due to the large resistance of series-connected batteries.

However, more important is the fact that both solar panels are almost identical to the performance indicators before and after the process of plywood, and the deviation is only 5%, which is within measurement error. These results illustrate several key advantages of this technology: versatility in substrate choices, high quality of the original performance, simplicity and scalability of the technological process, as well as additional savings on original reusable silicon substrates.

Zheng argues that such film solar battery can be sticked on any surface, on glass, on fabric, on paper, or on any other unusual for photoelectronic material, even on the walls of houses. And in each case, the battery will generate the same amount of electricity as traditional solar panels of the previous technology, while maintaining the effectiveness of 7.5%.

Plus, the battery sticker is easy to bend and it does not damage or reduce the effectiveness. Scientists anticipate that this is a wonderful property at a low cost will allow a new solar battery — stickers as power sources for smart wear and other electronic devices, where flexibility is important. published

Source: elektrovesti.net/48146_solnechnye-batarei-v-vide-samokleyashcheysya-plenki

In Germany, the largest building energy-efficient settlement

Vadim Zeland: Not "my tongue — my enemy", and the thoughts are my enemies