489

Created a new recyclable plastic

Plastic is a significant part of solid wastes of the planet. Although some types we are able to recycle a certain group of non-deformable plastics called "thermosetting plastic", widely common in the electronic industry has still not succumbed to the decomposition and processing.

In a recent study, the researchers described a method of producing a recyclable thermoset plastics that can be appropriately reused in production.

So, what is a thermosetting plastic, and why is it so difficult to recycle? First, let's consider the properties of thermoplastics, recyclable, and compare these two types.

Thermoplastic, which is used to produce bottles, Legos and guitar picks, can be repeatedly remelted and reshaped. If you hold a flame to such a plastic bottle, it becomes deformed and melts (although this is not recommended, as the resulting gaseous products are hazardous to health.)

But thermosetting plastics of which make cookware and components of electronic devices, such as PCB, retain strength and shape even when heated, making them ideal for the production of large and durable parts.

This ability to withstand temperatures associated with the special production steps, such as heating, pressing and the addition of catalysts that change the state of the material at the molecular level.

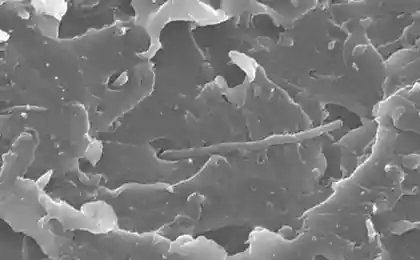

As a result of these steps, the molecular chains in thermosetting plastics form a very strong network of associated transversely. This prevents the melting of such items of plastics inherent in the thermoplastic and when heated, they crack or char.

Among the most common types of thermosetting plastics include epoxy, silicone and phenolic resins, and polyesters. In General, thermosetting plastics are known for their high adhesion, chemical and thermal stability, and excellent electrical conductivity and mechanical characteristics.

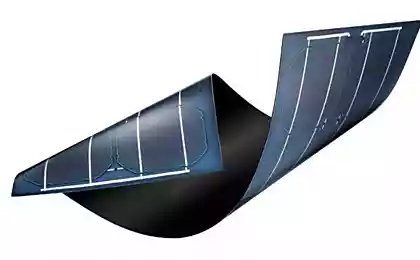

Because of these qualities, thermosetting plastics are used in numerous fields such as microelectronics, transportation and aerospace industries, as well as the production of varnishes and adhesives.

How to decompose non-degradable

The authors have created a recyclable thermoset plastics under the name "poly-hexahydrotriazine" which decompose in concentrated acid. The pure monomers (individual molecules of plastic material) was able to recover and re-use (polimerizuet) for the production of new products.

The properties of poly-hexahydrotriazine similar to conventional, non-recyclable thermosetting plastics: it is hard, thermo - and chemically stable, shows excellent resistance to the action of solvents and environmental factors, especially being reinforced by carbon nanotubes.

Moreover, by changing the combination and composition of monomers used for the reactions, the researchers were able to obtain an elastic gel with properties of self-healing. It is also possible to decompose in concentrated acid.

This work is a major step forward since a long time it was believed that thermoset plastics cannot be recycled.

Depending on the manufacturing process, substances can yield both thermoset and thermoplastic products:

Depending on the production process, using a substance that can produce products like thermosetting and thermal plastic:

• paraformaldehyde is often used for the production of thermoset plastics such as phenolic resin and a thermoplastic Polyoxymethylene. The latter is necessary for high-precision parts and high-quality technical components such as small gear and ball bearings;

• aromatic and aliphatic amines used for the production of thermosetting resins benzoxazinone required for heat resistant composites and electronic components. These amines are also raw material for the production of thermoplastics, such as aromatic nylons for high-strength Kevlar fibers (you can see them in bulletproof vests).

Just using different combinations of monomers, scientists have found a basis for the production of extremely diverse materials. The polymerization process based on well-studied reaction of amines with paraformaldehyde, which resulted in a new type of thermosetting plastics.

The method can be easily used on a large scale at existing plants and equipment for the chemical industry. She at the same time, technically accessible and affordable, and therefore are recyclable thermoset plastics can be obtained in commercial quantities.

Components made of this new material will replace the existing parts in many areas, such as the manufacture of modern electronic devices, automotive and aerospace industries.

But most importantly, most production of conventional thermoset plastics are sent to landfills. If the results of this study to apply on a large scale, we will get a great opportunity to reuse many plastic products.

Source: facepla.net