529

Chinese scientists have learned to recycle the plastic into diesel fuel

Plastic is both a curse and a blessing to our whole civilization. On the one hand, no plastics of various types of humanity would have developed quite differently. The invention of plastics in the time allowed to significantly accelerate technical progress. On the other hand, plastic is gradually infests our planet. This is especially true in the case of polyethylene — recycle it is not easy, and a large number of plastic film products and just thrown away. And then plastic ends up in seas and oceans, forming giant Islands of garbage violates the trophic chains in ecosystems of different types.

How can I solve this problem? At first glance, the solution lies on the surface: the collected plastics sent for recycling (remelting), create a new product. But the devil, as they say, is in the details. In order to recycle the plastic in the way suggested, you need to collect plastic waste, made of a single type of plastics. For example, transparent PET plastic bottles.

And even in this case, you need to make significant efforts to wash the bottles to such an extent that in the final melt was a minimal amount of impurities. It is possible but not too practical and quite expensive. Another way is processing of plastics without oxygen under high pressure and temperatures around 500°C. the result is a number of monomers, including styrene, terephthalic acid, methyl methacrylate. In modern conditions, only a fraction is recycled plastics, the rest is just thrown away. Not very practical. What should I do?

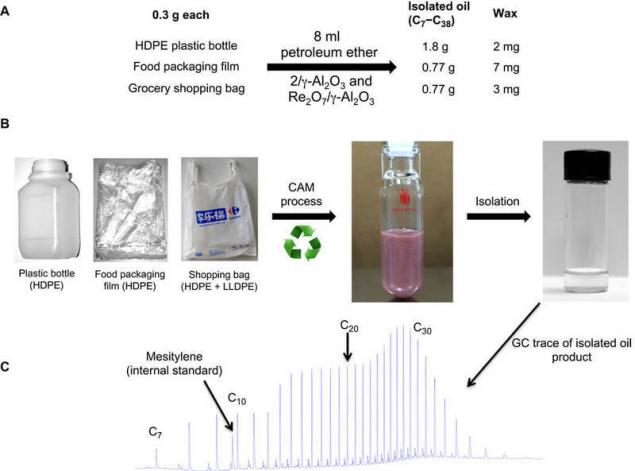

Recently, Chinese scientists from the Shanghai Institute of organic chemistry, headed by Saankhya Jia (Jia super spacious bed twin) proposed a new type of recycling that turns plastic into diesel fuel. It always takes a lot, so if the process is recycling economically beneficial, the plastic can be recycled in huge quantities. So far the Chinese only work with polyethylene.

Polyethylene — a thermoplastic polymer of ethylene, belongs to the class of polyolefins. Is an organic compound and has long molecules ...—CH2—CH2—CH2—CH2—..., where "—" represents covalent bonds between carbon atoms. The most common plastic in the world. Processing comes in the form of granules of from 2 to 5 mm. Polyethylene is produced by polymerization of ethylene. From polyethylene suitable for recycling and subsequent use. Polyethylene (except ultra-high molecular weight) may be processed by all known methods for plastics, such as extrusion, extrusion, injection molding, pneumatic molding.

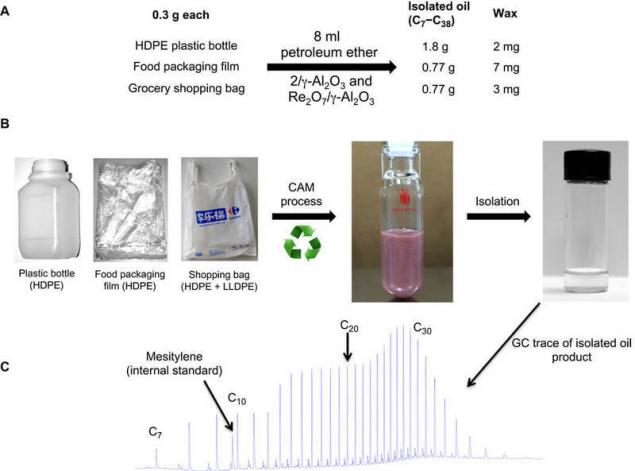

The process proposed by the Chinese, consists of two stages. And the first and second steps of converting polyethylene into diesel fuel require the use of catalysts. The first catalyst is composed of iridium (the Chinese have not disclosed details about the connection). This catalyst removes a portion of the hydrogen from the carbon. As a result, some single bonds between carbon atoms are converted to double. And this, in turn, opens up the possibility of using the second catalyst.

The composition and structure of the Chinese scientists also did not disclose, saying only that the catalyst comprises atoms of rhenium and aluminium. Are also used oil compounds (experts do not disclose the names of the components). Under the influence of a second catalyst to break the double bonds between carbon atoms, and to the ends of the formed components are joined, molecules of oil.

The types of polyethylene that can be recycled in a new way

The whole process is cyclical. As mentioned above, the first catalyst displaces the hydrogen atoms of polyethylene. But this hydrogen can be reused to convert the double bonds between carbon atoms in single. Such reactions can be repeated again and again. If you do it several hours, all the polythene is destroyed, leaving only the components of this connection. To increase the speed of reaction desired temperature is 150°C.

At the end of the process, the polyethylene is divided into three main types of components. The first type — simple organic compounds like butane, it can be used for other chemical reactions in the production. The second wax-like compounds that are necessary for obtaining the plastic. And the third type — diesel fuel.

Changing the various stages of the conversion process of polyethylene, the researchers can increase or decrease the output of each of these three components. According to Chinese scientists, most plastics can be divided into individual components with the help of this type of reaction. But for other types of plastic conditions the reaction will be somewhat different. The advantage of the proposed solutions is high efficiency and relatively mild conditions of the reaction.

Scientists who developed this method, I plan to patent it in 2017. Possible commercial use of the proposed process will begin this year. published

P. S. And remember, only by changing their consumption — together we change the world! ©

Source: geektimes.ru/post/277486/

How can I solve this problem? At first glance, the solution lies on the surface: the collected plastics sent for recycling (remelting), create a new product. But the devil, as they say, is in the details. In order to recycle the plastic in the way suggested, you need to collect plastic waste, made of a single type of plastics. For example, transparent PET plastic bottles.

And even in this case, you need to make significant efforts to wash the bottles to such an extent that in the final melt was a minimal amount of impurities. It is possible but not too practical and quite expensive. Another way is processing of plastics without oxygen under high pressure and temperatures around 500°C. the result is a number of monomers, including styrene, terephthalic acid, methyl methacrylate. In modern conditions, only a fraction is recycled plastics, the rest is just thrown away. Not very practical. What should I do?

Recently, Chinese scientists from the Shanghai Institute of organic chemistry, headed by Saankhya Jia (Jia super spacious bed twin) proposed a new type of recycling that turns plastic into diesel fuel. It always takes a lot, so if the process is recycling economically beneficial, the plastic can be recycled in huge quantities. So far the Chinese only work with polyethylene.

Polyethylene — a thermoplastic polymer of ethylene, belongs to the class of polyolefins. Is an organic compound and has long molecules ...—CH2—CH2—CH2—CH2—..., where "—" represents covalent bonds between carbon atoms. The most common plastic in the world. Processing comes in the form of granules of from 2 to 5 mm. Polyethylene is produced by polymerization of ethylene. From polyethylene suitable for recycling and subsequent use. Polyethylene (except ultra-high molecular weight) may be processed by all known methods for plastics, such as extrusion, extrusion, injection molding, pneumatic molding.

The process proposed by the Chinese, consists of two stages. And the first and second steps of converting polyethylene into diesel fuel require the use of catalysts. The first catalyst is composed of iridium (the Chinese have not disclosed details about the connection). This catalyst removes a portion of the hydrogen from the carbon. As a result, some single bonds between carbon atoms are converted to double. And this, in turn, opens up the possibility of using the second catalyst.

The composition and structure of the Chinese scientists also did not disclose, saying only that the catalyst comprises atoms of rhenium and aluminium. Are also used oil compounds (experts do not disclose the names of the components). Under the influence of a second catalyst to break the double bonds between carbon atoms, and to the ends of the formed components are joined, molecules of oil.

The types of polyethylene that can be recycled in a new way

The whole process is cyclical. As mentioned above, the first catalyst displaces the hydrogen atoms of polyethylene. But this hydrogen can be reused to convert the double bonds between carbon atoms in single. Such reactions can be repeated again and again. If you do it several hours, all the polythene is destroyed, leaving only the components of this connection. To increase the speed of reaction desired temperature is 150°C.

At the end of the process, the polyethylene is divided into three main types of components. The first type — simple organic compounds like butane, it can be used for other chemical reactions in the production. The second wax-like compounds that are necessary for obtaining the plastic. And the third type — diesel fuel.

Changing the various stages of the conversion process of polyethylene, the researchers can increase or decrease the output of each of these three components. According to Chinese scientists, most plastics can be divided into individual components with the help of this type of reaction. But for other types of plastic conditions the reaction will be somewhat different. The advantage of the proposed solutions is high efficiency and relatively mild conditions of the reaction.

Scientists who developed this method, I plan to patent it in 2017. Possible commercial use of the proposed process will begin this year. published

P. S. And remember, only by changing their consumption — together we change the world! ©

Source: geektimes.ru/post/277486/