466

Scientists produce fuel from plastic waste

Polyethylene, plastic and its derivatives, used in the manufacture of most disposable drinks packaging, produced a stunning volume are more than 100 million metric tons per year, most of which is in landfills.

Currently, scientists from the University of California, Irvine (UCI) and the Shanghai Institute of organic chemistry (SIOC) in China found a way to turn the waste into workable liquid fuels.

"Synthetic plastics are a fundamental part of modern life, but our use of them in large volumes creates serious environmental problems," says a chemist at the University of California Jibin Guan (Guan Zhibin). "The goal of our research is to examine plastic pollution, but also achieve actual results in the creation of a new source of liquid fuels".

High density polyethylene (HDPE), low density (LDPE) and linear low density polyethylene (LDL) are types of polyethylene used to manufacture packaging for beverages and food products, as their chemical composition makes them inert, thus they do not degrade and do not interact with any of the chemical substances, which usually we are going to eat.

Unfortunately, this also means that since they do not react to most chemical compounds, they do not decompose into components with the aid of those substances, which are commonly used for other recyclable materials.

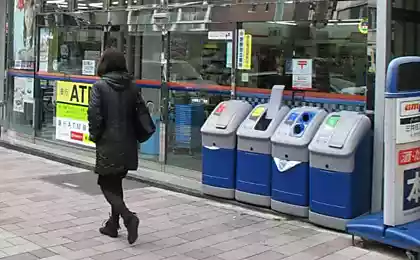

This fact often leads to various alternative methods of disposal or recycling of plastic bottles in everything from plastic pellets, plastic ropes, as well as the construction of entire villages out of plastic bottles.

Unfortunately, the standard industrial way to recycle such as plastic waste, typically includes less "friendly" forms of disposal. Actually, the standard methods are likely to do more harm than good, because you use caustic chemicals or they require heating materials to more than 370° C, to break chemical bonds of polymers that the process produces harmful byproducts, such as hydrocarbon gas, oil, wax, and soot in uncontrolled amounts.

To help the situation and create the best method in industrial scale recycling and recovery of chemicals, the researchers from a joint American-Chinese project invented a new way to destroy the polyethylene, which is produced by a smaller quantity of toxic byproducts and more useful connection.

Use of by-products of petrochemical manufacturing, known as alkanes (saturated hydrocarbons in which the atoms of hydrogen and carbon are located in a branched formation, and the bonds are carbon-carbon are single), the scientists were able to separate and recover the polymer molecules into other useful compounds.

The process is what is called cross-alkanoyl exchange, which is essentially a chemical reaction of a double dissolution, where two parts of two substances to form two new substances. In this case, the method selectively degrades a number of PE plastics into fuel and paraffin in milder conditions and more controllable way than in a normal industrial process of plastic destruction and reconstruction. In fact, according to the researchers, the new method can completely degrade PE compounds into usable oil and wax in one day at a temperature of only 175 ° C.

In the future, the researchers will study the effectiveness of the method, including increasing the catalyst activity and lifetime, reducing operating costs and developing processes to recycle other types of plastic waste into useful products. published

P. S. And remember, only by changing their consumption — together we change the world! ©

Source: facepla.net/the-news/tech-news-mnu/5490-%D1%82%D0%BE%D0%BF%D0%BB%D0%B8%D0%B2%D0%BE-%D0%B8%D0%B7-%D0%BF%D0%BB%D0%B0%D1%81%D1%82%D0%B8%D0%BA%D0%B0.html

Currently, scientists from the University of California, Irvine (UCI) and the Shanghai Institute of organic chemistry (SIOC) in China found a way to turn the waste into workable liquid fuels.

"Synthetic plastics are a fundamental part of modern life, but our use of them in large volumes creates serious environmental problems," says a chemist at the University of California Jibin Guan (Guan Zhibin). "The goal of our research is to examine plastic pollution, but also achieve actual results in the creation of a new source of liquid fuels".

High density polyethylene (HDPE), low density (LDPE) and linear low density polyethylene (LDL) are types of polyethylene used to manufacture packaging for beverages and food products, as their chemical composition makes them inert, thus they do not degrade and do not interact with any of the chemical substances, which usually we are going to eat.

Unfortunately, this also means that since they do not react to most chemical compounds, they do not decompose into components with the aid of those substances, which are commonly used for other recyclable materials.

This fact often leads to various alternative methods of disposal or recycling of plastic bottles in everything from plastic pellets, plastic ropes, as well as the construction of entire villages out of plastic bottles.

Unfortunately, the standard industrial way to recycle such as plastic waste, typically includes less "friendly" forms of disposal. Actually, the standard methods are likely to do more harm than good, because you use caustic chemicals or they require heating materials to more than 370° C, to break chemical bonds of polymers that the process produces harmful byproducts, such as hydrocarbon gas, oil, wax, and soot in uncontrolled amounts.

To help the situation and create the best method in industrial scale recycling and recovery of chemicals, the researchers from a joint American-Chinese project invented a new way to destroy the polyethylene, which is produced by a smaller quantity of toxic byproducts and more useful connection.

Use of by-products of petrochemical manufacturing, known as alkanes (saturated hydrocarbons in which the atoms of hydrogen and carbon are located in a branched formation, and the bonds are carbon-carbon are single), the scientists were able to separate and recover the polymer molecules into other useful compounds.

The process is what is called cross-alkanoyl exchange, which is essentially a chemical reaction of a double dissolution, where two parts of two substances to form two new substances. In this case, the method selectively degrades a number of PE plastics into fuel and paraffin in milder conditions and more controllable way than in a normal industrial process of plastic destruction and reconstruction. In fact, according to the researchers, the new method can completely degrade PE compounds into usable oil and wax in one day at a temperature of only 175 ° C.

In the future, the researchers will study the effectiveness of the method, including increasing the catalyst activity and lifetime, reducing operating costs and developing processes to recycle other types of plastic waste into useful products. published

P. S. And remember, only by changing their consumption — together we change the world! ©

Source: facepla.net/the-news/tech-news-mnu/5490-%D1%82%D0%BE%D0%BF%D0%BB%D0%B8%D0%B2%D0%BE-%D0%B8%D0%B7-%D0%BF%D0%BB%D0%B0%D1%81%D1%82%D0%B8%D0%BA%D0%B0.html

Azerbaijan will build the largest wind farm in the Caspian sea

How to get out of resentment of a lifetime