427

Independent gas supply: a device and system capabilities

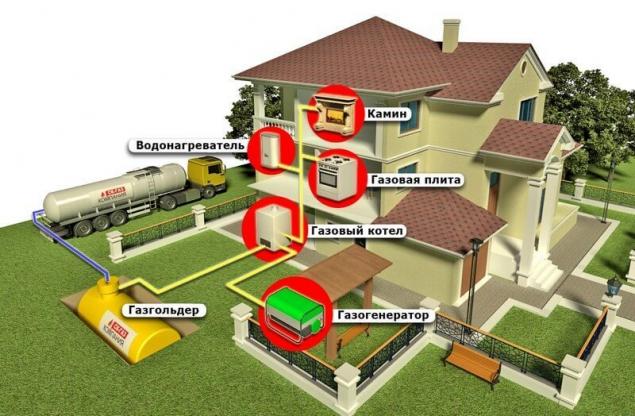

Clean Outback beckons to the inhabitants of polluted cities the opportunity to breathe fresh air and relax surrounded by almost untouched nature. However, in such areas often do not have the usual benefits of civilization. If you equip the Autonomous Sewerage and water supply is relatively simple, with heating the house much more complicated. You can try to be heated with solid fuels or install an electric boiler. In any case, it would be expensive, and in the first case is also very difficult solution. The most economical way of power supply is recognized as gasification. If it is not possible to connect to a gas line, it is always possible to arrange independent gas supply.

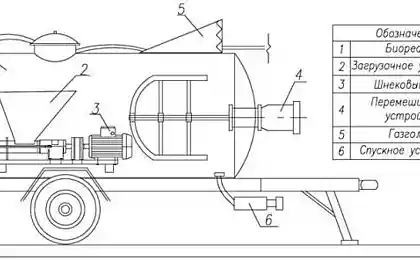

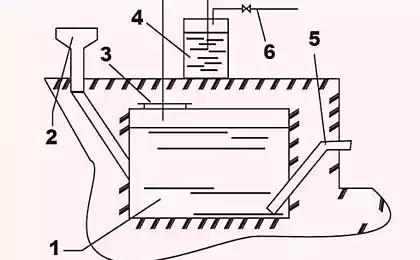

The cost of such system is quite high, so if the gas is only required for cooking, to install its not worth it. It will be economically justified only in the case when the fuel is used to heat homes and to generate electricity. The main elements of such a system:

— Gasometer is a reservoir, which is pumped liquefied gas mixture;

— high pressure pipeline connecting the reservoir with the evaporator;

— evaporator where the pressure is equalized to atmospheric;

— low pressure line, the outlet gas mixture to the consuming device.

Gas tanks are made of steel sheet of 10 mm thickness and can withstand pressure of 1.6 MPa. Each tank is equipped with factory a personal number. They are designed for surface or underground installation. In addition, there are horizontally and vertically arranged containers. The first is much more common. They have a large area of evaporation, which leads to their high performance. Horizontal devices require a connection to the evaporator, whereas vertical tanks can do without it, because the outer surface of such underground tanks are able to extract heat from the ground.

Vertical tanks can be installed to great depths, which further protects the contents from exposure to low temperatures in the cold season. Regardless of the method of installation, tanks equipped with corrosion protection. It can be as special coating, and galvanic protection, which is mounted near the gas tank. The tank is equipped with pressure-reducing head, which protects from external influences, the control unit and control. Be sure gas tanks are equipped with pressure relief and safety shut-off valves, level gauge and ground.

From the reservoir the gas mixture enters the evaporator installation. Here its pressure is reduced to atmospheric by increasing the amount of evaporating gas. For the operation of the device will require coolant, which can be used steam or hot liquid. For heating appliances with a capacity below 100 kW, this installation is not required, because natural evaporation is sufficient for their smooth running. You can connect to one tank multiple boilers. In this case, to operate without evaporator their total capacity should also not exceed 100 KW.

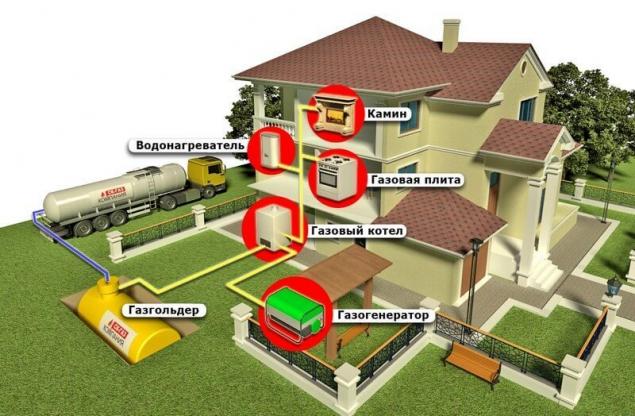

Properly designed and installed Autonomous gas supply system makes it possible to heat a house of any size, to provide hot water and cooking, as well as to supply electricity to the buildings. It is fully Autonomous, allowing the owner to choose the volume of consumption. You can be sure that blackouts and sudden lowering of pressure, so frequent in the gas lines, will not. Despite the high cost of installation of an Autonomous system, it is quite pays for itself quickly. On average, it takes three years.

Heating LPG very economical. It is quite comparable to the cost of heating, running on the main gas. Arbitrary leakage and associated ignition of the gas mixture is practically impossible. The life of the equipment, subject to correct installation is about 30 years. Injection of gas into the tank is performed as necessary. In average once in 1.5-2 years. Another undoubted advantage of the system – high level of environmental protection. As fuel is used Propano-butane mixture, which is burned without waste and does not pollute the soil by accidental spill.

The main condition for effective operation of the system can be considered responsible attitude to its development and exploitation, because the gas is considered to be potentially dangerous. Any negligence in handling it is unacceptable. You need to know that filling the tank more than 85% is unacceptable. This is especially true in the warm season. Heated, the gas mixture expands, leading to increased pressure on the vessel wall, which can lead to depressurization.

The gas mixture is heavier than air and leaking it drops and "flowing" in the low areas, accumulating in the basement and basement premises. When mixed with air formed an explosive mixture. Therefore, the boiler and all the appliances, liquefied gas, shall be installed only above ground level. In addition, you must provide adequate ventilation to the premises regularly to control all joints of the equipment for possible leaks and to install the detectors. All activities for installation and maintenance must be performed only by certified professionals. Only in this case, the operation of the system of Autonomous gas supply will be safe. published

Source: www.stroitelstvo365.ru/gazosnabzhenie/avtonomnoe-gazosnabzhenie-ustrojstvo-i-vozmozhnosti-sistemi

The cost of such system is quite high, so if the gas is only required for cooking, to install its not worth it. It will be economically justified only in the case when the fuel is used to heat homes and to generate electricity. The main elements of such a system:

— Gasometer is a reservoir, which is pumped liquefied gas mixture;

— high pressure pipeline connecting the reservoir with the evaporator;

— evaporator where the pressure is equalized to atmospheric;

— low pressure line, the outlet gas mixture to the consuming device.

Gas tanks are made of steel sheet of 10 mm thickness and can withstand pressure of 1.6 MPa. Each tank is equipped with factory a personal number. They are designed for surface or underground installation. In addition, there are horizontally and vertically arranged containers. The first is much more common. They have a large area of evaporation, which leads to their high performance. Horizontal devices require a connection to the evaporator, whereas vertical tanks can do without it, because the outer surface of such underground tanks are able to extract heat from the ground.

Vertical tanks can be installed to great depths, which further protects the contents from exposure to low temperatures in the cold season. Regardless of the method of installation, tanks equipped with corrosion protection. It can be as special coating, and galvanic protection, which is mounted near the gas tank. The tank is equipped with pressure-reducing head, which protects from external influences, the control unit and control. Be sure gas tanks are equipped with pressure relief and safety shut-off valves, level gauge and ground.

From the reservoir the gas mixture enters the evaporator installation. Here its pressure is reduced to atmospheric by increasing the amount of evaporating gas. For the operation of the device will require coolant, which can be used steam or hot liquid. For heating appliances with a capacity below 100 kW, this installation is not required, because natural evaporation is sufficient for their smooth running. You can connect to one tank multiple boilers. In this case, to operate without evaporator their total capacity should also not exceed 100 KW.

Properly designed and installed Autonomous gas supply system makes it possible to heat a house of any size, to provide hot water and cooking, as well as to supply electricity to the buildings. It is fully Autonomous, allowing the owner to choose the volume of consumption. You can be sure that blackouts and sudden lowering of pressure, so frequent in the gas lines, will not. Despite the high cost of installation of an Autonomous system, it is quite pays for itself quickly. On average, it takes three years.

Heating LPG very economical. It is quite comparable to the cost of heating, running on the main gas. Arbitrary leakage and associated ignition of the gas mixture is practically impossible. The life of the equipment, subject to correct installation is about 30 years. Injection of gas into the tank is performed as necessary. In average once in 1.5-2 years. Another undoubted advantage of the system – high level of environmental protection. As fuel is used Propano-butane mixture, which is burned without waste and does not pollute the soil by accidental spill.

The main condition for effective operation of the system can be considered responsible attitude to its development and exploitation, because the gas is considered to be potentially dangerous. Any negligence in handling it is unacceptable. You need to know that filling the tank more than 85% is unacceptable. This is especially true in the warm season. Heated, the gas mixture expands, leading to increased pressure on the vessel wall, which can lead to depressurization.

The gas mixture is heavier than air and leaking it drops and "flowing" in the low areas, accumulating in the basement and basement premises. When mixed with air formed an explosive mixture. Therefore, the boiler and all the appliances, liquefied gas, shall be installed only above ground level. In addition, you must provide adequate ventilation to the premises regularly to control all joints of the equipment for possible leaks and to install the detectors. All activities for installation and maintenance must be performed only by certified professionals. Only in this case, the operation of the system of Autonomous gas supply will be safe. published

Source: www.stroitelstvo365.ru/gazosnabzhenie/avtonomnoe-gazosnabzhenie-ustrojstvo-i-vozmozhnosti-sistemi