397

Custom 3D-printed magnesium high-capacity battery

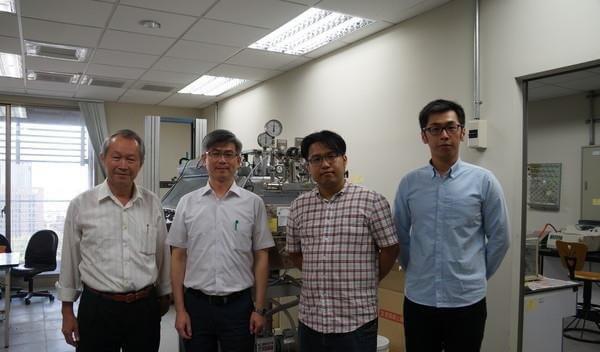

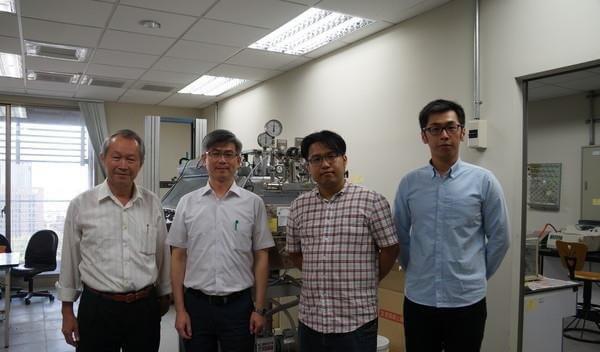

The research team from the National University Chenggong printed magnesium battery. According to Taiwan's development three times more efficient than lithium and Nickel products with higher capacity and speed of charging. In addition, additive manufacturing of these power sources needs much less time than traditional methods.

Supervise professors of the Department of materials science And FEI Hong and Lu Chuan-Sheng. Motivation for the project was cumbersome, expensive, difficult to manufacture and just outdated batteries for electric cars. Existing powder batteries are produced in at least four stages, including the production of powders, obtaining a paste by mixing with a binder, pressing and heat treatment. On average, the process takes about twenty-four hours. Laser powder 3D printing allows to simplify the production cycle to just two stages and to reduce the production time to three minutes, combining several steps in one.

The capacity of 3D-printed battery is easily increased by using additional layers, plates, and further increase the maximum charge, the researchers were able to achieve by making an anode of magnesium powder. The developers believe that their experiment disproves the commonly accepted opinion on additive technologies, such as the methods of prototyping and customization.

Short production time, demonstrated in the experiences of the team, allow us to consider 3D printing as a method of serial production, though in one particular case. published

Source: www.energy-fresh.ru/news/?id=13584

Supervise professors of the Department of materials science And FEI Hong and Lu Chuan-Sheng. Motivation for the project was cumbersome, expensive, difficult to manufacture and just outdated batteries for electric cars. Existing powder batteries are produced in at least four stages, including the production of powders, obtaining a paste by mixing with a binder, pressing and heat treatment. On average, the process takes about twenty-four hours. Laser powder 3D printing allows to simplify the production cycle to just two stages and to reduce the production time to three minutes, combining several steps in one.

The capacity of 3D-printed battery is easily increased by using additional layers, plates, and further increase the maximum charge, the researchers were able to achieve by making an anode of magnesium powder. The developers believe that their experiment disproves the commonly accepted opinion on additive technologies, such as the methods of prototyping and customization.

Short production time, demonstrated in the experiences of the team, allow us to consider 3D printing as a method of serial production, though in one particular case. published

Source: www.energy-fresh.ru/news/?id=13584

Sono German Motors is planning serial production of electric cars with solar panels

Samurai and Oedipus: Family History