1147

Goznak Perm

Good evening. I decided to arrange for you a trip to Perm Printing Factory Goznak. I'll show you how to make money.

It will be a little text and many photos.

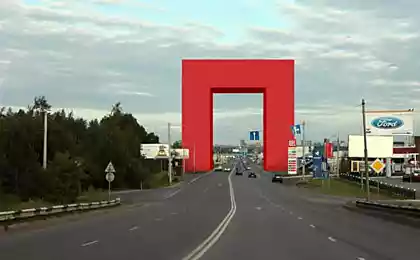

To start: Every resident of Perm, certainly saw this large building located on the highway Cosmonauts. What is "Goznak", and there is printing money, even a first-grader knows.

It is worth noting that this company does not only manufacture of banknotes - is producing excise duty stamps for tobacco and alcohol products, and Russian passports, documents, traffic police, as well as plastic credit cards.

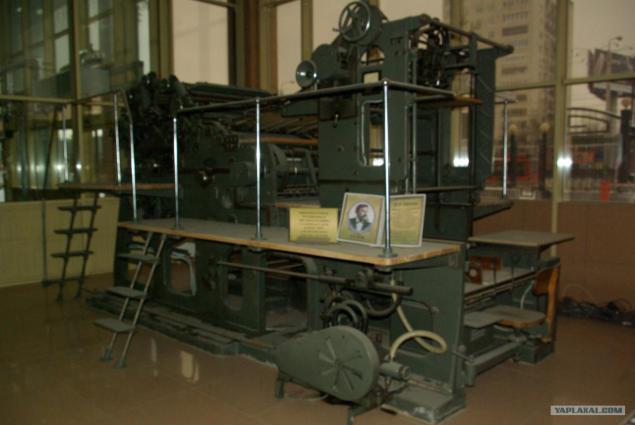

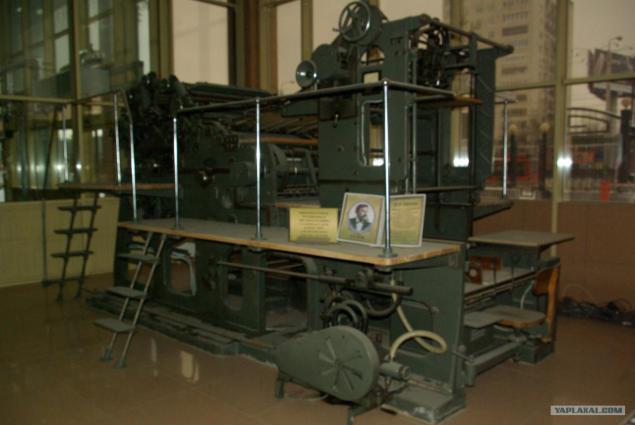

We have begun the way to the entrance of the factory. Here, as a tribute to the traditions of many years of Goznak and its history, is set printing machine. Until a few decades ago, these machines worked in manufacturing plants.

Two minutes of walking through the long corridors, and we were in a new production building - one of the largest and most modern plants in the world. Large building of several floors, and on each of them presses.

Semi-finished product is stored in a special automated warehouse from which the products are issued and received by one processing operation to another without the aid of people. In all production areas and storage rooms maintain a certain temperature and humidity needed for high-quality printing and semi-drying.

Printing banknotes - a multi-stage process, from the receipt of a white paper to the finished banknote is held for about a month. This month, the paper is subjected to sealing a few times on different printing presses and post-treatment on the lines of cutting and packaging of finished products

White paper comprises special elements for protection from forgery - a watermark, special fibers and high bulk paper security threads. Here it comes from Krasnokamsk and St. Petersburg Paper Mill of Goznak.

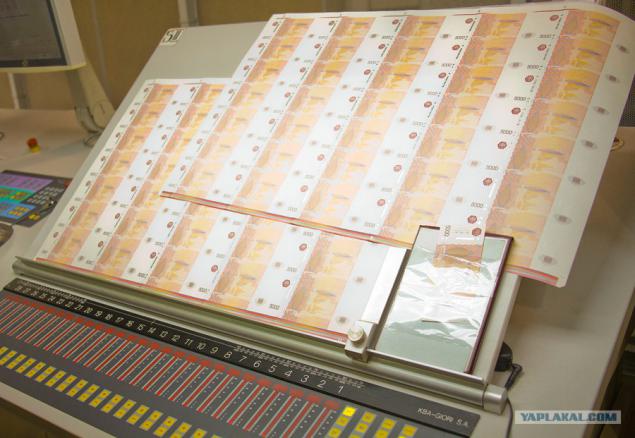

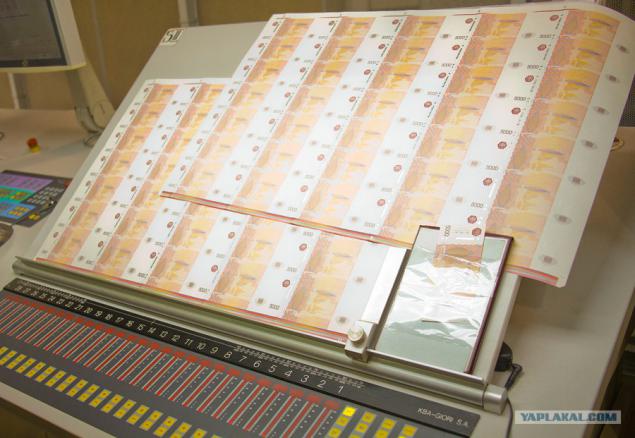

The first of manufacturing operations for the production of banknote production - Orel print. Paper car immediately sealed on both sides, ensuring thus a good compatibility of the printed image on the front and back sides, it is one of the signs of the authenticity of banknotes. I should add that at a time on such a machine, you can print up to 20 different colors.

Machine Orel print

Further along the process chain takes screen, and then intaglio printing. Intaglio printing (or printing from an engraving) is a type of intaglio printing. Intaglio printing paper is sealed on both sides sequentially.

Printing intaglio front recipe

Intaglio printing reproduces the most vivid image on a banknote. One indication of this printing, it is relief (tactility), since the recording sheet is great pressure - tens tons per contact strip 1 cm. Educate professions - Orel printer and gravure printing can only be Goznak.

Printing Machine intaglio

This flow of money you can watch endlessly. But we disappoint you, it's still not finished banknotes. The next step for a brand new five thousandth bill - microperforation. Openings in the form of a nominal value (in this case 5000) laser burn on a special machine - the presence of these small openings in size, is one of the signs of the authenticity of banknotes.

The machine for laser micro perforation

The last stage of print production - numbering. Printing machine seals the unique numbers on each banknote.

Printing machine numbering

Then comes the turn, finishing - sheets are cut into specimens and specimens are formed into packs, and banding are packaged in shrink-wrap.

Workers in the shops do not look at the money with delight as come journalists and treat them as "normal" products.

and finally a few photos ...

...

...

...

...

...

final photo ...

via prm.ru

Posted in [mergetime] 1386609281 [/ mergetime]

Thank you all

Source:

It will be a little text and many photos.

To start: Every resident of Perm, certainly saw this large building located on the highway Cosmonauts. What is "Goznak", and there is printing money, even a first-grader knows.

It is worth noting that this company does not only manufacture of banknotes - is producing excise duty stamps for tobacco and alcohol products, and Russian passports, documents, traffic police, as well as plastic credit cards.

We have begun the way to the entrance of the factory. Here, as a tribute to the traditions of many years of Goznak and its history, is set printing machine. Until a few decades ago, these machines worked in manufacturing plants.

Two minutes of walking through the long corridors, and we were in a new production building - one of the largest and most modern plants in the world. Large building of several floors, and on each of them presses.

Semi-finished product is stored in a special automated warehouse from which the products are issued and received by one processing operation to another without the aid of people. In all production areas and storage rooms maintain a certain temperature and humidity needed for high-quality printing and semi-drying.

Printing banknotes - a multi-stage process, from the receipt of a white paper to the finished banknote is held for about a month. This month, the paper is subjected to sealing a few times on different printing presses and post-treatment on the lines of cutting and packaging of finished products

White paper comprises special elements for protection from forgery - a watermark, special fibers and high bulk paper security threads. Here it comes from Krasnokamsk and St. Petersburg Paper Mill of Goznak.

The first of manufacturing operations for the production of banknote production - Orel print. Paper car immediately sealed on both sides, ensuring thus a good compatibility of the printed image on the front and back sides, it is one of the signs of the authenticity of banknotes. I should add that at a time on such a machine, you can print up to 20 different colors.

Machine Orel print

Further along the process chain takes screen, and then intaglio printing. Intaglio printing (or printing from an engraving) is a type of intaglio printing. Intaglio printing paper is sealed on both sides sequentially.

Printing intaglio front recipe

Intaglio printing reproduces the most vivid image on a banknote. One indication of this printing, it is relief (tactility), since the recording sheet is great pressure - tens tons per contact strip 1 cm. Educate professions - Orel printer and gravure printing can only be Goznak.

Printing Machine intaglio

This flow of money you can watch endlessly. But we disappoint you, it's still not finished banknotes. The next step for a brand new five thousandth bill - microperforation. Openings in the form of a nominal value (in this case 5000) laser burn on a special machine - the presence of these small openings in size, is one of the signs of the authenticity of banknotes.

The machine for laser micro perforation

The last stage of print production - numbering. Printing machine seals the unique numbers on each banknote.

Printing machine numbering

Then comes the turn, finishing - sheets are cut into specimens and specimens are formed into packs, and banding are packaged in shrink-wrap.

Workers in the shops do not look at the money with delight as come journalists and treat them as "normal" products.

and finally a few photos ...

...

...

...

...

...

final photo ...

via prm.ru

Posted in [mergetime] 1386609281 [/ mergetime]

Thank you all

Source: