1046

Ventilation in the kitchen with their hands: what you need to know

The design of ventilation and extraction systems for kitchens, in fact, very simple. However, there are many nuances, ignoring that, we have a chance to create an incorrect and inefficient ventilation. Ventilation that instead of clean air, will, literally, to poison our lives.

Natural kitchen ventilation and the law of conservation of volume of air

Long gone are the days when the residents of private houses and city apartments were content with the natural ventilation of kitchens. Despite the relatively low efficiency of such systems (especially in the time of cooking), the principles of their arrangement will always be relevant. The fact that the continuous operation of natural ventilation is possible only under certain conditions. Namely: ventilation ducts must provide unobstructed drainage of air masses from the premises, while the flow of fresh air to the kitchen must be carried out continuously.

Efficient operation of ventilation systems is possible only when the volume of air leaving the room will be equal to the amount of air coming into the kitchen.To ensure compliance with the first condition can be timely cleaning and maintenance of ventilation ducts. The second conditions is possible with the use of simple air inlets in the structure of a ventilating system.

Just a few decades ago the majority of dwellings were equipped with wooden Windows. Their integrity is, as we know, left much to be desired. Therefore, the issue of admission of fresh air into the apartment or house was decided with virtually no human intervention. Today, when we deal with sealed insulating glass and powerful cooker hoods, valve forced ventilation built into the design of the plastic window or mounted on the wall, is not a whim but a necessity.

The simplest supply-and-exhaust ventilation with their hands

If your house has a natural ventilation system with an exhaust hole in the kitchen, the odor of pies in the bedroom you virtually not face. If your house is under construction, to take care of the availability of such a system is the time. Functioning normally, she will constantly renew the air in the kitchen environment, and the lack of effectiveness it is always possible to improve, equip a small exhaust fan.

If you live in a private house, roof fan mounted in the duct, will help to modernize the design of the system, no noise during operation.

If you live in an apartment, the fan in the vent, qualitatively improve the process of admission of fresh air into the room.

A good solution would be a duct fan, can significantly enhance the capacity of the exhaust flow.

Using these devices, you your hands can turn natural ventilation in a simple supply-and-exhaust system.

Rules for creating air ducts

The natural ventilation system in which there are no auxiliary fans, at any time can play over you a malicious joke. We are talking about such a physical phenomenon as a "rollover draft". It is observed when under the influence of external factors and exhaust flow loses power or even changes direction (outside air begins to flow into the room through the ventilation shaft). Therefore, ventilation duct, it is advisable to roof, while its height should exceed the height of the ridge. This rule is true both for natural ventilation and for systems with forced air extraction.

Pipe and duct that will pass through cold areas (attic and exterior space of a building), should be warmed.

Vent, descended to the street through an ordinary horizontal hole in the wall, in the absence of the pressure difference inside and outside the building will perform its function only when the fan.

Kitchen hood

We reviewed the features of the systems that operate continuously and are designed to ensure efficient ventilation in the kitchen. Now let's talk about kitchen hoods – devices that are included in most "hot" hours, helping us to get rid of the smell of cooking on the stove food.

Extractor hood, unlike the standard ventilation system helps capture smoke, steam and grease particles into the air during cooking. Therefore, the need to install the exhaust device in addition to the existing ventilation system is obvious.

Thus, the extractor fan in the kitchen is needed, but what hood to use?

According to the principle of the hoods are divided into flow and recirculation. Flowing withdrawn air from the room outside, while recirculation – filter out impurities, and return the air back into the room.

Recirculating exhaust devices are not popular. And there are several reasons: the need for a frequent replacement of the filter elements, low efficiency and inability to take excess heat out of the room.

Given all the shortcomings of the recycling plants, they should be used only in exceptional cases.

Flow hood removes the impurities that are formed during the cooking outside. By way of installing flow hoods are suspended, recessed, corner, dome and island. No matter what type of installation is the hood, the exhaust air from the room should be organized on the same principle. It lies in the fact that the existing range hood should only be connected to a separate vent channel.

To connect the hood to the shared ventilation channel, and especially, to the flue is forbidden! Carbon monoxide and exhaust air in this case can get back into the room.

In homes with outdated ventilation systems isolated channel to connect the hood, as a rule, absent. And how to get out the hood in a General ventilation shaft is not, additional ventilation channel, you must create a separate order. Appropriate, but inefficient solution in this case will be the purchase of recirculating aquaculture systems.If you are afraid to ruin the facade of your house (flat) stains from grease, soot and steam, for drawing in the wall, you can do a separate horizontal channel. Output vent will be placed directly on the outer surface of the wall. Such a structure is desirable to provide a non-return valve (if its presence is not foreseen in the design of the hoods) or inertial grid.

Ideally, the duct for drawing must be created on the same principles, which creates ventilation channels. Namely, to a duct provided for natural draft when off the hood, it should be put on the roof (just above the ridge).

Special attention should be paid to insulation of the duct in the attic and on the street that will prevent the formation of condensation.

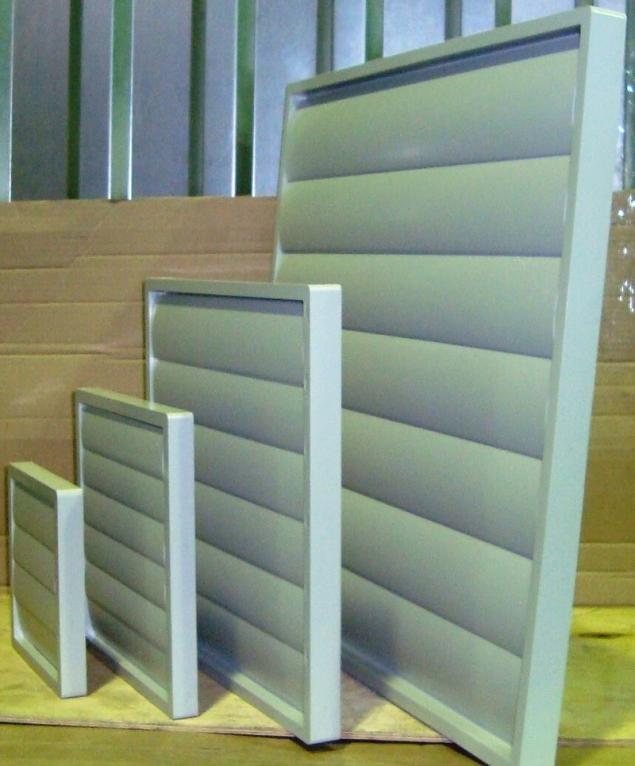

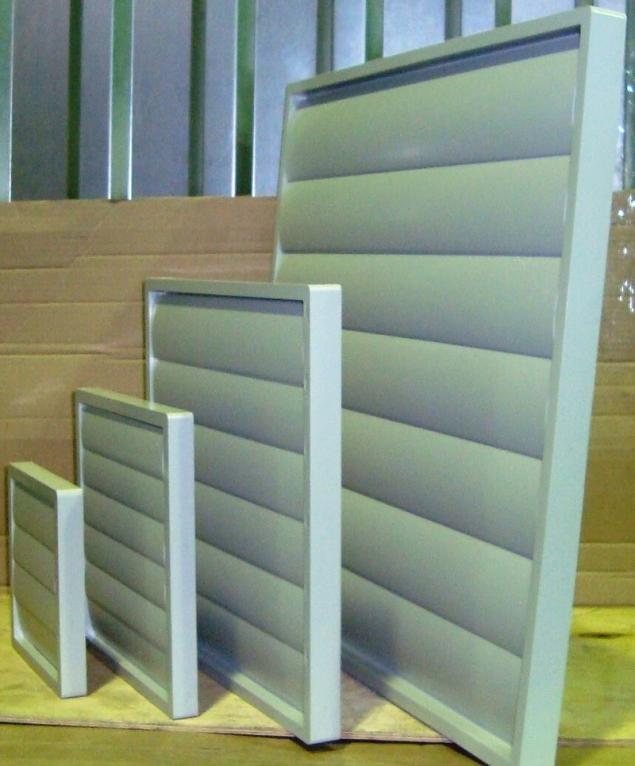

As for the ventilation outlets: it is advisable to purchase ready-made products that are in compliance with existing standards are insulated at time of manufacture.

The material of the duct

The material inlet is used to connect the cooker hood must meet the following conditions:

Create minimal resistance to air flow. To have high corrosion resistance. To have a sufficient area of the inner section. Taking into account the first condition, the flexible corrugated tube, the walls of which have sufficiently high resistance, it is recommended to use exclusively to connect the exhaust vent.

Corrugation, if it is possible, it is preferable to substitute smooth galvanized round tube or square section.

That rust did not destroy the duct, many people are eager to introduce its design of a plastic sewer pipe with a thick cross section. But this material is prone to accumulate body fat, while safe, these pipes can not be called. Their use may lead to fire (once the oil ignited in the hot pan while running hood). For this reason, from the use of sewer pipes to be abandoned in advance.

Calculate the power ofChoosing the hood for your own kitchen, each of us thinks about what needs to be output from this device. In all cases, this indicator depends on the area of the kitchen. If the area your kitchen less than 10 m2 (inclusive) and height – 2,5-2,7 m, the extractor, passing through her 280-350 m3 air for one hour, it will be able to meet your needs. If the kitchen area more, and the power of the device should be appropriate.

In principle, this parameter can be obtained from sellers, and it is possible to calculate according to the formula: V=S*H*10*1.3. In it: S and H are the area and height of the room, V is the volume (m3/h).

published

Source: www.forumhouse.ru/articles/house/6886

Natural kitchen ventilation and the law of conservation of volume of air

Long gone are the days when the residents of private houses and city apartments were content with the natural ventilation of kitchens. Despite the relatively low efficiency of such systems (especially in the time of cooking), the principles of their arrangement will always be relevant. The fact that the continuous operation of natural ventilation is possible only under certain conditions. Namely: ventilation ducts must provide unobstructed drainage of air masses from the premises, while the flow of fresh air to the kitchen must be carried out continuously.

Efficient operation of ventilation systems is possible only when the volume of air leaving the room will be equal to the amount of air coming into the kitchen.To ensure compliance with the first condition can be timely cleaning and maintenance of ventilation ducts. The second conditions is possible with the use of simple air inlets in the structure of a ventilating system.

Just a few decades ago the majority of dwellings were equipped with wooden Windows. Their integrity is, as we know, left much to be desired. Therefore, the issue of admission of fresh air into the apartment or house was decided with virtually no human intervention. Today, when we deal with sealed insulating glass and powerful cooker hoods, valve forced ventilation built into the design of the plastic window or mounted on the wall, is not a whim but a necessity.

The simplest supply-and-exhaust ventilation with their hands

If your house has a natural ventilation system with an exhaust hole in the kitchen, the odor of pies in the bedroom you virtually not face. If your house is under construction, to take care of the availability of such a system is the time. Functioning normally, she will constantly renew the air in the kitchen environment, and the lack of effectiveness it is always possible to improve, equip a small exhaust fan.

If you live in a private house, roof fan mounted in the duct, will help to modernize the design of the system, no noise during operation.

If you live in an apartment, the fan in the vent, qualitatively improve the process of admission of fresh air into the room.

A good solution would be a duct fan, can significantly enhance the capacity of the exhaust flow.

Using these devices, you your hands can turn natural ventilation in a simple supply-and-exhaust system.

Rules for creating air ducts

The natural ventilation system in which there are no auxiliary fans, at any time can play over you a malicious joke. We are talking about such a physical phenomenon as a "rollover draft". It is observed when under the influence of external factors and exhaust flow loses power or even changes direction (outside air begins to flow into the room through the ventilation shaft). Therefore, ventilation duct, it is advisable to roof, while its height should exceed the height of the ridge. This rule is true both for natural ventilation and for systems with forced air extraction.

Pipe and duct that will pass through cold areas (attic and exterior space of a building), should be warmed.

Vent, descended to the street through an ordinary horizontal hole in the wall, in the absence of the pressure difference inside and outside the building will perform its function only when the fan.

Kitchen hood

We reviewed the features of the systems that operate continuously and are designed to ensure efficient ventilation in the kitchen. Now let's talk about kitchen hoods – devices that are included in most "hot" hours, helping us to get rid of the smell of cooking on the stove food.

Extractor hood, unlike the standard ventilation system helps capture smoke, steam and grease particles into the air during cooking. Therefore, the need to install the exhaust device in addition to the existing ventilation system is obvious.

Thus, the extractor fan in the kitchen is needed, but what hood to use?

According to the principle of the hoods are divided into flow and recirculation. Flowing withdrawn air from the room outside, while recirculation – filter out impurities, and return the air back into the room.

Recirculating exhaust devices are not popular. And there are several reasons: the need for a frequent replacement of the filter elements, low efficiency and inability to take excess heat out of the room.

Given all the shortcomings of the recycling plants, they should be used only in exceptional cases.

Flow hood removes the impurities that are formed during the cooking outside. By way of installing flow hoods are suspended, recessed, corner, dome and island. No matter what type of installation is the hood, the exhaust air from the room should be organized on the same principle. It lies in the fact that the existing range hood should only be connected to a separate vent channel.

To connect the hood to the shared ventilation channel, and especially, to the flue is forbidden! Carbon monoxide and exhaust air in this case can get back into the room.

In homes with outdated ventilation systems isolated channel to connect the hood, as a rule, absent. And how to get out the hood in a General ventilation shaft is not, additional ventilation channel, you must create a separate order. Appropriate, but inefficient solution in this case will be the purchase of recirculating aquaculture systems.If you are afraid to ruin the facade of your house (flat) stains from grease, soot and steam, for drawing in the wall, you can do a separate horizontal channel. Output vent will be placed directly on the outer surface of the wall. Such a structure is desirable to provide a non-return valve (if its presence is not foreseen in the design of the hoods) or inertial grid.

Ideally, the duct for drawing must be created on the same principles, which creates ventilation channels. Namely, to a duct provided for natural draft when off the hood, it should be put on the roof (just above the ridge).

Special attention should be paid to insulation of the duct in the attic and on the street that will prevent the formation of condensation.

As for the ventilation outlets: it is advisable to purchase ready-made products that are in compliance with existing standards are insulated at time of manufacture.

The material of the duct

The material inlet is used to connect the cooker hood must meet the following conditions:

Create minimal resistance to air flow. To have high corrosion resistance. To have a sufficient area of the inner section. Taking into account the first condition, the flexible corrugated tube, the walls of which have sufficiently high resistance, it is recommended to use exclusively to connect the exhaust vent.

Corrugation, if it is possible, it is preferable to substitute smooth galvanized round tube or square section.

That rust did not destroy the duct, many people are eager to introduce its design of a plastic sewer pipe with a thick cross section. But this material is prone to accumulate body fat, while safe, these pipes can not be called. Their use may lead to fire (once the oil ignited in the hot pan while running hood). For this reason, from the use of sewer pipes to be abandoned in advance.

Calculate the power ofChoosing the hood for your own kitchen, each of us thinks about what needs to be output from this device. In all cases, this indicator depends on the area of the kitchen. If the area your kitchen less than 10 m2 (inclusive) and height – 2,5-2,7 m, the extractor, passing through her 280-350 m3 air for one hour, it will be able to meet your needs. If the kitchen area more, and the power of the device should be appropriate.

In principle, this parameter can be obtained from sellers, and it is possible to calculate according to the formula: V=S*H*10*1.3. In it: S and H are the area and height of the room, V is the volume (m3/h).

published

Source: www.forumhouse.ru/articles/house/6886