564

The steam engine in the tower

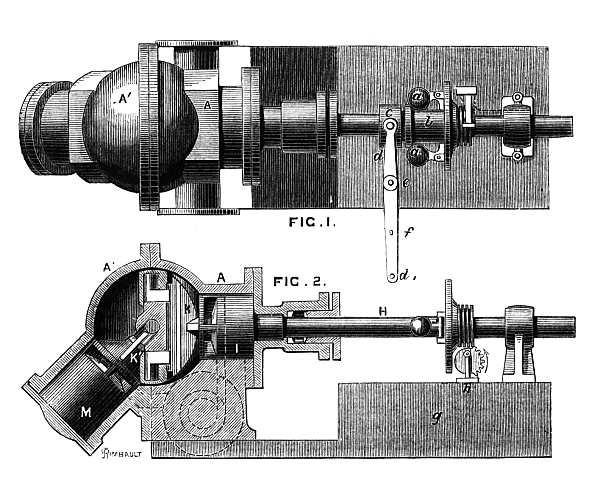

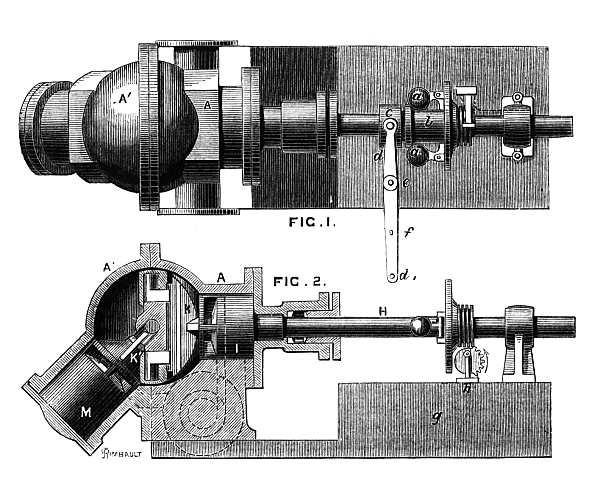

Instead of the usual cylinder in this steam machine was a sphere. Hollow sphere, inside of which everything happened.

In the sphere was rotated and oscillated the disk on each side of which is "thrown" up and down the quarters of the globe. As you can see, it is impossible to explain, so GIF:

a little slower, sifco

Red arrows — fresh steam blue edition exhaust.

Shafts placed at an angle of 135 degrees to each other. Pairs through the hole in the quarter came under pressed to the disk plane, expanding (producing useful work) and after turning quarters went through the same hole. Quarters, thus, fulfilled the functions of valve/removal of steam. Loose disk did what in an ordinary steam engine the piston makes. A crank mechanism was not at all, because it was not necessary to convert reciprocating motion into rotary.

Master node:

While on one side of the quarters was working stroke (expansion of the steam), on the other side was made blank (release of waste steam). On the other side of the disc the same occurred with a shift in phase by 90 degrees. Because of the mutual position of the quarter-disk attached to the rotation and oscillations.

In fact, it was a driveline with an internal source of energy. Green disc cross driveline commit the same rotational-vibrational motion:

The rotation is transmitted to the two shafts coming out of the motor. To remove the energy could be both, but in practice, judging by the drawings, to drive the used one.

As noted by the French magazine "La Nature" 1884 year, spherical the engine is made higher compared to the piston counterparts speed and hence well suited to drive an electric generator.

The engine had low levels of noise and vibration and was very compact. A motor with an internal diameter of bowl 10 cm and a rotation frequency of 500 rpm at a steam pressure of 3 ATM issued 1 horsepower at 8.5 ATM — 2.5 HP, The large model with a diameter of 63 cm has a capacity of 624 "horses".

But. The spherical motor was difficult to manufacture, require large steam consumption. It was produced and some time really operated to drive generators in the British Navy and on the Railways Great Eastern Railway (installed on a steam boiler, and was used for electric cars). However, due to these shortcomings did not stick.

P. S. it Should be noted that the inventor of a spherical horse engine of Beauchamp tower (the Beauchamp Tower) is not lost to engineering.

Apparently, he was the first who observed the oil wedge in the bearings and measured the pressure in it. Ie uses modern engineering research Mr. tower still.

Gleaned here and there.

Source: geektimes.ru/post/279724/

In the sphere was rotated and oscillated the disk on each side of which is "thrown" up and down the quarters of the globe. As you can see, it is impossible to explain, so GIF:

a little slower, sifco

Red arrows — fresh steam blue edition exhaust.

Shafts placed at an angle of 135 degrees to each other. Pairs through the hole in the quarter came under pressed to the disk plane, expanding (producing useful work) and after turning quarters went through the same hole. Quarters, thus, fulfilled the functions of valve/removal of steam. Loose disk did what in an ordinary steam engine the piston makes. A crank mechanism was not at all, because it was not necessary to convert reciprocating motion into rotary.

Master node:

While on one side of the quarters was working stroke (expansion of the steam), on the other side was made blank (release of waste steam). On the other side of the disc the same occurred with a shift in phase by 90 degrees. Because of the mutual position of the quarter-disk attached to the rotation and oscillations.

In fact, it was a driveline with an internal source of energy. Green disc cross driveline commit the same rotational-vibrational motion:

The rotation is transmitted to the two shafts coming out of the motor. To remove the energy could be both, but in practice, judging by the drawings, to drive the used one.

As noted by the French magazine "La Nature" 1884 year, spherical the engine is made higher compared to the piston counterparts speed and hence well suited to drive an electric generator.

The engine had low levels of noise and vibration and was very compact. A motor with an internal diameter of bowl 10 cm and a rotation frequency of 500 rpm at a steam pressure of 3 ATM issued 1 horsepower at 8.5 ATM — 2.5 HP, The large model with a diameter of 63 cm has a capacity of 624 "horses".

But. The spherical motor was difficult to manufacture, require large steam consumption. It was produced and some time really operated to drive generators in the British Navy and on the Railways Great Eastern Railway (installed on a steam boiler, and was used for electric cars). However, due to these shortcomings did not stick.

P. S. it Should be noted that the inventor of a spherical horse engine of Beauchamp tower (the Beauchamp Tower) is not lost to engineering.

Apparently, he was the first who observed the oil wedge in the bearings and measured the pressure in it. Ie uses modern engineering research Mr. tower still.

Gleaned here and there.

Source: geektimes.ru/post/279724/