637

SAW robot crawls, climbs and swims with only one engine

If you want to move the machine may have recourse to the wheels and the tracks, to walk or to go into the exotic level of crawling and swimming. Ways to make the robot move described by many. Sometimes it may seem that nothing new has come up. But it is not so. In a recent paper from the University of Zarrouk David Ben-Gurion in the Negev describes the wave-like robot-worm, which is driven by only one actuator.

The robot is called: single actuator wave-like robot or SAW. Its wave-like structure is pushing it forward or backward. To rotate the steering wheel needs. This design is not only good moves on land, but can climb into narrow crevices and swim in the water.

The researchers say that the principles borrowed from crawling snakes. Although progress SAW robot can be compared with the methods of the worm's movement, analogy conditional. earthworm's body is elongated in one part due to thinning. The front end is moving forward, keep up the back part, which is reduced for him. The process is repeated. SAW same goes sine wave on the surface. Principles of robot motion similar to that used by some small sea animals in a much smaller scale: microscopic organisms swim using flagella

Video demonstration robot

.. Minimalism, simplicity of movements and high performance - that's over what Zarrouk time working. In an interview with IEEE Spectrum Zarrouk said that back in 2004 he was a student, tried to recreate the wave motion similar to what exist in living organisms. While working on his doctoral Zarrouk came to the idea of using wave motion for systems inside the digestive system. A simple system with one motor can be reduced and the use of movement within the intestine.

A couple of years ago Zarrouk read product design course and talked about the spring. Then he noticed that in one projection spring - circle, the other - a sine wave. If the spring is rotated, the wave moves uncomplicated. Zarrouk put easy, so interested in the forefront

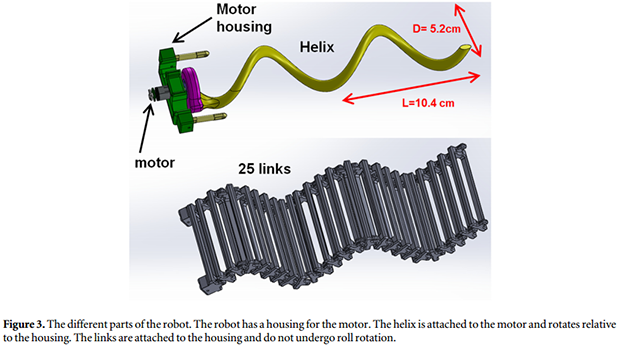

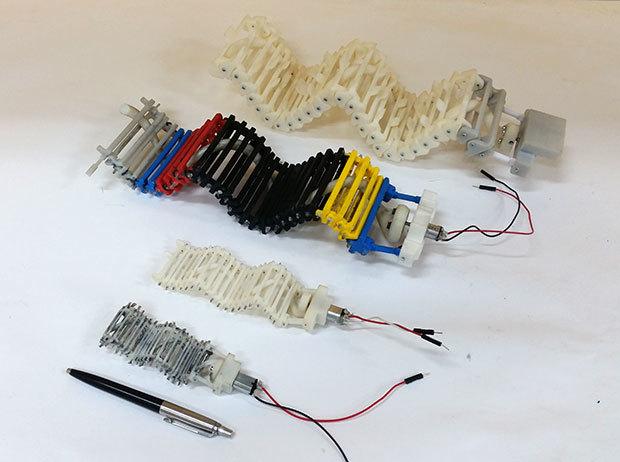

Upper figure:. Motor rotates the spiral relative to the housing. Lower picture: 25 units surround the spiral, they are attached to the body and does not rotate

. The SAW one engine. He rotates the robot Ridge - rigid spiral. The latter is surrounded by a series of links that have been printed the 3D-printer. These units are movable in the same plane, as if part of a bicycle chain. Spiral turns, as links go up and down. This links are moving so that when in contact with the surface of the robot is pushed forward.

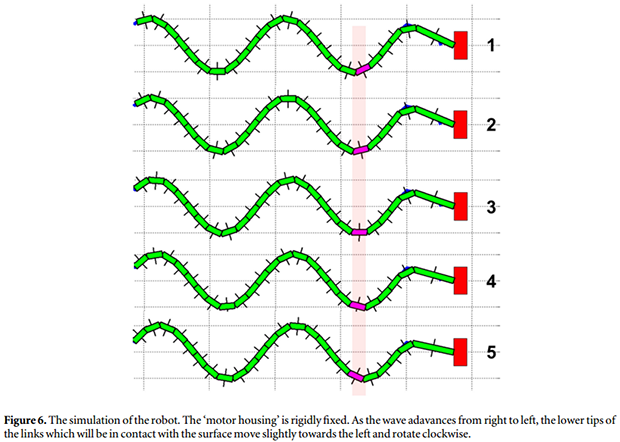

wave goes from right to left, and links in contact with the ground a little move to the left and rotate clockwise .

SAW robot can only move forward or backward. To reverse fairly steep spiral in the opposite direction. It helps to steer the two wheels on the body, which otherwise are passive they do not lead to machine operation. It may seem that the only way to speed up the movement - rotating spiral faster. But researchers have added to the links of the teeth, which allow you to make the movement of seven waves for six cycles. So speed has increased by 13%.

80,344,989

Special teeth do not prevent links to move relative to each other.

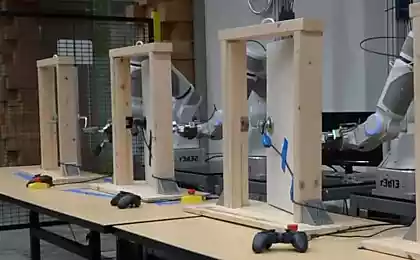

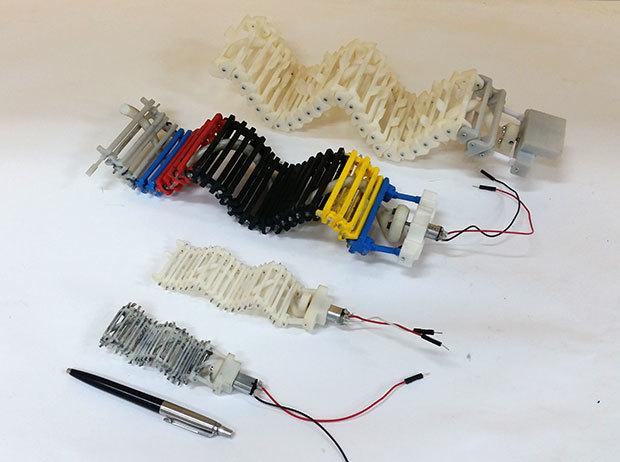

Several models were constructed of various sizes. The largest (colored) accelerates 5, 6 waves per second or 57 centimeters per second. It can climb set between two narrow surfaces at a speed of 8 cm / s. Enclosed in a waterproof case floats model at a speed of 6 cm / s. SAW is working not only on a flat floor lab, he overcomes the terrain and passes the rocks and grass.

SAW - not just a toy. Now it could be reduced to the size of the handle (the lowest sample in the photo above). The term robot can be miniaturized to such an extent that he will be able to remove the human intestine and take samples for biopsy. Work on the further reduction is already underway.

As Zarrouk says the robot is almost maintenance-free, which is unusual for a dynamic structure obtained by 3D-printing. In the future, steering system change - the current is not too elegant. Researchers want to try to articulate two robots SAW through the hinge. And if you get on the fly to change the frequency of the waves and the amplitude, the robot will be able to better adapt to different surfaces, wriggle through a tube diameters and many optimize traffic for each of the liquids

Single actuator wave-like robot (SAW).: design, modeling, and experiments

Source: geektimes.ru/post/278924/

Molineux task: to completely restore vision to the blind prevents the brain

Why are you all infuriates