770

Electricity from biomass, or "people's" power generator

Electric theme - one of the most popular and talked about. Light is necessary for all: and those who are just starting to be built, and suburban residents, already obzhivshim their plots. That's only electricity tends to periodically "disappearing". Broken wires, disconnection, or simply "light" was not enough. The reasons are many. The problem is compounded by the fact that all the engineering systems in the building are dependent on reliable and uninterrupted supply of electricity.

Another workshop off from the city mains made the Californian Jim Mason's look at the problem from a different angle. He started looking for an alternative source of power, which once and for all would help him to become independent from the municipal authorities. Ten years of hard work, the foundation of the company, and to light a compact gas generator that produces electricity from woody biomass.

The device, resembling a miniature refinery occupies area standard Euro pallet. At the peak of the power generator produces up to 20 kW, and with prolonged use - 15-18 kilowatts of electricity

.

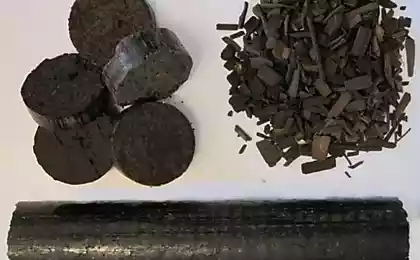

Current generated as follows. The bunker-furnace unit is laid biomass. It can be crushed waste derevoproizvodstva husks of sunflower seeds, nut shells, sawdust, etc. Further fuel "being pushed" into the long decay mode. As a result of the slow combustion of biomass, wood gas is released during its thermal decomposition (pyrolysis). The resulting gaseous fuel is used to operate a three liter four-cylinder internal combustion engine, which in turn drives a generator to produce electric current.

Gasifier power plant produces as a one-, two-, three-phase and AC voltages from 120 to 480V. Power is fully automatic and requires minimal human intervention. Users simply download the bunker fuel biomass and once a day to remove ash from the special automatic drive.

To generate 1 kW power plant consumes 1.5 kg of biomass. The level of power generated depends on the type of fuel loaded into the hopper, as the volume of gas produced depends on the condi biomass degree of its drying, etc.

Experimentally, it was found that the best fuel for the operation of the plant is walnut shells, and the worst - waste bamboo production

. Engineers emphasize that the installation is not designed to run on coal, municipal solid waste, recycled tires and plastic waste.

Thanks to the mobility and relatively low weight installation, it can be transported on a trailer or in the back of a pickup vehicle. By combining several units, it is possible to assemble a power station to power a small settlement. Optionally, to install an apparatus is provided that is connected to the engine cooling radiator. Due to this, it made "material removal" of thermal energy, which is then used to heat water in the heating system. Also, the installation can be combined with other energy sources, including alternative.

Full-scale installation tests were carried out in West Africa, and it is fully proven its performance in hot climates. According to the calculations of experts, the installation will be useful to farmers, owners of small woodworking industries, land and homeowners who want to have a powerful and compact electric power source and does not depend on the energy companies.

Another workshop off from the city mains made the Californian Jim Mason's look at the problem from a different angle. He started looking for an alternative source of power, which once and for all would help him to become independent from the municipal authorities. Ten years of hard work, the foundation of the company, and to light a compact gas generator that produces electricity from woody biomass.

The device, resembling a miniature refinery occupies area standard Euro pallet. At the peak of the power generator produces up to 20 kW, and with prolonged use - 15-18 kilowatts of electricity

.

Current generated as follows. The bunker-furnace unit is laid biomass. It can be crushed waste derevoproizvodstva husks of sunflower seeds, nut shells, sawdust, etc. Further fuel "being pushed" into the long decay mode. As a result of the slow combustion of biomass, wood gas is released during its thermal decomposition (pyrolysis). The resulting gaseous fuel is used to operate a three liter four-cylinder internal combustion engine, which in turn drives a generator to produce electric current.

Gasifier power plant produces as a one-, two-, three-phase and AC voltages from 120 to 480V. Power is fully automatic and requires minimal human intervention. Users simply download the bunker fuel biomass and once a day to remove ash from the special automatic drive.

To generate 1 kW power plant consumes 1.5 kg of biomass. The level of power generated depends on the type of fuel loaded into the hopper, as the volume of gas produced depends on the condi biomass degree of its drying, etc.

Experimentally, it was found that the best fuel for the operation of the plant is walnut shells, and the worst - waste bamboo production

. Engineers emphasize that the installation is not designed to run on coal, municipal solid waste, recycled tires and plastic waste.

Thanks to the mobility and relatively low weight installation, it can be transported on a trailer or in the back of a pickup vehicle. By combining several units, it is possible to assemble a power station to power a small settlement. Optionally, to install an apparatus is provided that is connected to the engine cooling radiator. Due to this, it made "material removal" of thermal energy, which is then used to heat water in the heating system. Also, the installation can be combined with other energy sources, including alternative.

Full-scale installation tests were carried out in West Africa, and it is fully proven its performance in hot climates. According to the calculations of experts, the installation will be useful to farmers, owners of small woodworking industries, land and homeowners who want to have a powerful and compact electric power source and does not depend on the energy companies.