1655

How to make inexpensive solar collector with his own hands

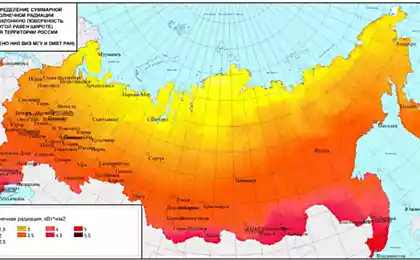

Solar collectors - a good way to save energy energoresursy.Solnechnaya - free, so at least 6-7 months in a year, you can get warm water for household needs. And in the other months - and even help the heating system

. You can make your own solar collector. To do this, you will need materials and tools that can be purchased at most hardware stores. Or what you will find in his garage.

The following technology is used in the project, "including the sun - live comfortably." It was specifically designed for the project by the German company Solar Partner Sued, which professionally engaged in the sale, installation and service of solar collectors and panels fotoeletricheskih.

The main idea - cheap and cheerful. For the manufacture of collector used is quite simple and common materials that you can buy at your local store, or even find in his garage. The efficiency of the collector is at a decent level. It is lower than the factory model, but the price difference is completely compensated for this shortcoming.

There are various types of solar water heaters, but they are all based on a simple principle: the black surface absorbs heat from the sun, then this heat is transferred to the water. The simplest model can be constructed from readily available materials and does not require pumps or other electrical equipment. Efficient solar collector can be used even in the winter thanks to the use of non-freezing fluids - antifreeze

. This system is a passive solar collector and is not dependent on electricity. It goes without pumps. Hot fluid moves between the collector and the tank on the principle of convection, thanks to a simple rule - always heated liquid rises

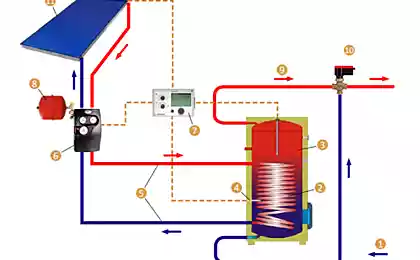

. The principle of operation of the solar collector is as follows:

The sun heats the fluid in the reservoir

The heated fluid rises through the manifold and pipe-in accumulator tank

When the hot fluid enters the heat exchanger installed in a water tank, the heat transferred from the heat exchanger in the water tank

Fluid in a heat exchanger, cooled, helically moves down and enters in the holes of the bottom of the tank back to the reservoir

Water heated in the tank is accumulated in the upper part of the tank

Cold water from the water supply / reservoir enters the bottom of the tank

The heated water is removed through an outlet at the top of the tank.

As long as the sun shines on the collector, the absorber tubes in liquid is heated, it is moved into the tank and thus constantly circulates. This process heats the water in the tank just a few hours under intense solar radiation.

The main element of the collector - absorber. It consists of a metal sheet, which is welded to the metal tubes. Several tubes are mounted vertically and are welded to the two large-diameter pipes, arranged horizontally. These thick pipes for fluid inlet and outlet should be arranged parallel to each other. A fluid inlet (bottom of the absorber) and the outlet (top of the absorber) should be placed on different sides panel (diagonally). To connect the thicker pipes, drill hole diameter of the vertical pipe.

For better heat transfer from the metal plate to the pipes it is important to ensure maximum contact with the tube plate. Welding should be along the element. It is important that the sheet metal and tube abut each other.

The absorber is placed in a wooden frame and covered with glass, which protects the collector and creates a greenhouse effect inside.

It uses ordinary window glass. The optimum thickness - 4 mm, while maintaining good reliability and weight ratio. It is desirable to correct the glass area divided into several parts. It is more convenient and safer to work with him.

The use of multiple layers of glass or glass will increase efficiency, but will increase the weight of the structure and cost of the system.

The sun's rays pass through the glass and heated manifold and the glazing prevents heat loss. Glass also prevents the movement of air in the absorber without a collector would quickly lose heat due to wind, rain, snow or low outside temperature as a whole.

Rama should be treated with antiseptic and paint for exterior use.

The housing is made through holes for cold and heated liquid outlet from the reservoir.

Sam absorber heat-resistant paint coating. Conventional black paint at high temperatures are beginning to peel off or evaporate, which leads to darkening of the glass. The paint must be completely dry before you attach the glass cover (to prevent condensation).

Under the absorber is laid insulation. The most commonly used mineral wool. The main thing is to withstand relatively high temperatures during the summer (sometimes more than 200 degrees).

The bottom frame is closed OSB, plywood, boards, etc. The main requirement for this stage - to make sure that the bottom of the reservoir is protected from moisture inside

. To fix the frame in the glass making grooves or strips attached along the inner side of the frame. When calculating the size of the frame should be considered that a change in the weather (temperature, humidity) during the year of its configuration will vary slightly. Therefore, on each side of the frame leave a few millimeters stock.

On the slot or bar attached rubber window seal (D- or E-shaped). It is placed on the glass to which is applied the same way seal. On top of it all fixed galvanized tin. Thus, the glass is firmly secured in the frame, the seal protects the absorber from the cold and moisture, namely, the glass will not be damaged when the wooden frame will "breathe».

The joints between the sheets of glass are insulated gasket or silicone.

Storage tank. It contains the collector heated water, so it is worth to take care of its insulation.

The tank can be used as:

broken electric boilers

oxygen cylinders

barrels for food use

The main thing - remember that in the sealed tank pressure will be created depending on the pressure of the water system to which it is connected. Not every container capable of withstanding the pressure of several atmospheres.

The tank make holes for inlet and outlet of the heat exchanger, the input of cold water and heated intake.

spiral heat exchanger is placed in the tank. For him, using copper, stainless steel, or plastic. The heated water through a heat exchanger will rise up, so it should be placed at the bottom of the tank.

The collector is connected to the tank by means of pipes (for example plastic or reinforced plastic) conducted from the manifold to the tank through a heat exchanger and back into the reservoir. It is very important to prevent heat loss: the path from the tank to the consumer should be as short as possible, and the tube must be very well insulated

.

Expansion tank - it is a very important element of the system. It is an open container, located at the top point of the fluid circulation circuit. For the expansion tank can be used as a metal and plastic utensils. With the help of controlled pressure in the reservoir (due to the fact that the heating fluid is expanded, the tube may crack). To reduce heat loss as the tank must be isolated. If air is present in the system, it may also escape through the tank. Through the expansion tank occurs as the liquid filling the reservoir.

More features of the structure, the necessary materials and rules for establishing the solar collector can be found by downloading a practical guide on the project website.