1750

The drainage system on your site-as select and install

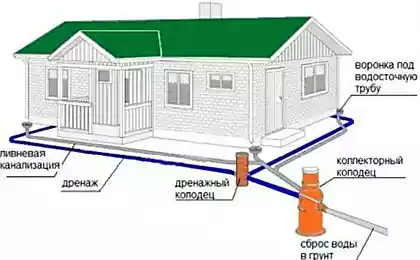

With the arrival of spring, many suburban residents are faced with the problem of flooding areas and basements. In today's article we will look at features of selection and installation of drainage wells.

Drainage wells: species

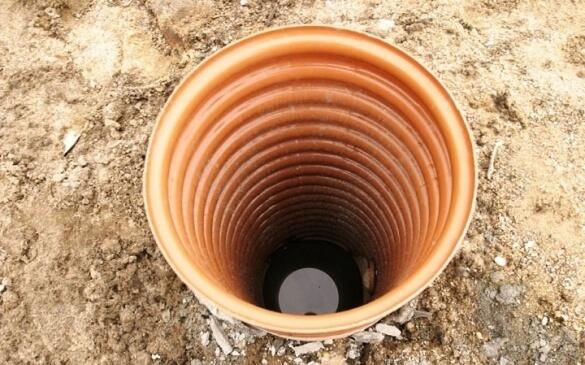

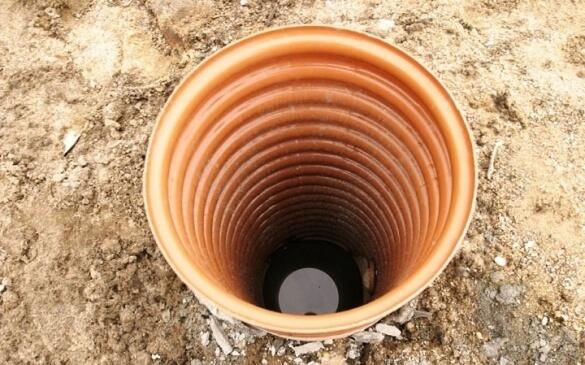

Drain well - an element of the drainage system, intended for its normal functioning, as well as monitoring and cleaning of drainage pipes. Drain well (in the presence of water-absorbent soil) is used as a filter, and the absorption of the well. Or (if the soil has a weak water absorption) is the intake. Based on this definition, drainage wells can be divided into the following types:

Rotary and inspection.

Absorption (filter).

Water inlet (cumulative).

Consider drainage wells each type in more detail.

Rotary shafts are installed in places turn drains (drains). This can be a corner of the foundation, elevation changes, convergence node multiple drains or places most susceptible to clog. A manhole is performed visual inspection and subsequent access to clean drains. Inspection and rotary shafts provided with a sealed bottom and a lid.

Razmer wells is chosen so that, if necessary could carry drainage water flushing pressure molding. The diameter of such wells ≈ 300 to 500 mm. If it is assumed that access to the system should go down the drain well people, the well diameter is increased to 1 meter or more.

Manholes are installed in the ground turns drains when changing the slope and Elevations.

The optimal distance between manholes on straight sections - 40 m, the maximum distance - 50 meters. By turning the drains in the projections of buildings manhole can not do, if the distance from the pivot to the nearest manhole no more than 20 meters. If the section between manholes drainage pipes made several turns, then the wells are mounted by 1 turn.

The choice of the filter (absorption) of the well caused the type of soil on the site. Purpose of this well the name implies - the water received by the drain of a well, is going in the receiver is filtered (eg, through the gravel layer) and through the holes, or if the well has no bottom, goes into the lower soil layers. Those. the soil should have sufficient water absorption capacity to cope with the volume of water flowing into the well. Thus ground, for example, can be coarse sand. Otherwise, the presence of water pressure, the water received by the water well, will not be able to escape into the soil, and the well will overflow with time.

Cumulative sealed wells are used in areas with high ground water table, clay soil and the ground, not having a high water absorption capacity. And in areas with deep water inlet layers doburitsya to whom and to arrange a vertical drainage is economically disadvantageous.

This well is the ultimate reservoir of the drainage system.

To the extent that the collected water is pumped out and the drain pump is reset for the plot border to the nearby ditch or used for irrigation.

Therefore, before you start the construction of drainage, it is necessary to produce a hydrogeological study of the soil and determine its composition and the ability of water absorption. Without these data, drainage construction - the construction blindly without understanding the essence of the processes occurring in the soil

. The easiest way "by eye» check the ability of the soil to water absorption - to dig a shallow hole at the site, pour water into it and see how fast it will go. If the water goes away slowly or does not go away, you should think about it, and where it is going to go away, if you build a filter drain well. Trying to "dig" to the plenum layer, without the knowledge of the geology of a particular area, it may be doomed to failure.

And in the area and water (effluent) can be quite different, with a different level of occurrence. It - surface water - livnёvka, derived from snowmelt and rain, perched - one of the types of groundwater, etc. Those. drainage - is not simply divert water. We need to know what kind of water you need to take.

What do drain well, and how to mount the drainage system

This is a question often asked by novice developers. The construction market offers two main options - buy a ready drain well of plastic or make drainage wells from RC rings. Both options have both pluses and minuses.

In this case, as a drainage well may be used with the RC ring sealed bottom. Rotary and manholes - alternatively, plastic, too, with a sealed bottom. Diameter - 40 cm Slop part in all wells -.. At least 30 cm

With a high groundwater table problem may be the installation of concrete manhole bases, as when digging water quickly arrives and floods and trench drains and a place where a pit is dug under the ring. In this case, you must first perform a dewatering. To do this, in the course of the track, made drains and digging pits, from which water is pumped out forcibly. After that, the installation of drainage wells and laying drains.

Holes for drainage pipes in the concrete ring can be cut without the use of a special crown.

This is done so - is marked hole of the required diameter, around the perimeter of the drilled through holes, and then the circle knocked

.

For the manufacture of such rings need flat ground, 2 pieces of sheet metal not less than 0.8 mm thick (the same width but different dina). The wire reinforcement (steel mesh can be used), to prepare a concrete mixer samomesnogo concrete and simple device for fixation of the formwork.

It is also important to make a very draining.

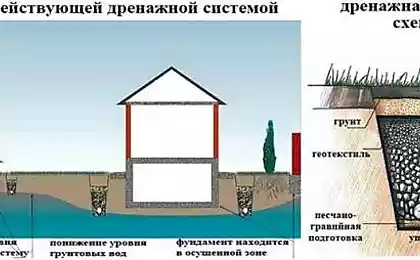

According to its users - this scheme is a classic radial drainage. For the calculation of the drainage should be noted that the depth of the drain depends on the type of underground structure, which is given water + soil Cp (Cp - coefficient of filtration, it characterizes the permeability of the soil) + the type and level of underground water and water pressure

Next, we add to the lowest mark of the pipe, a member of the central accumulation well, deepening the bottom for regulating the pump capacity. It is possible to calculate how many rings need.

The length of each beam drains - up to 40 meters. At the end of each beam bury a sealed chamber for washing. For example, of concrete rings. Slopes - drop marks be within 0.005 (for example, 40 meters x 0.005 = 0.2 m at the bottom)

. Drains conclude in a two- or three-layer sprinkled - the so-called inverse filter. This dusting, depending on the composition of the soil, can be made of crushed granite (the estimated fraction) and the coarse sand on the principle that we maintain a consistent transition from the pipe fractions (the largest) to fraction (finer) drained soil

.

When drainage device should be remembered that the traditional geotextile (GT), which is wrapped in a pipe with gravel and which is put on the tube is not a back-flow filter element. This is a necessary measure required to separate the layers. Those. HT is needed to prevent mixing of the layers, which allows us to simplify the selection of a reverse filter components because of the paucity of choice fractions (gravel, sand), presented in the construction market.

The right way to do the reverse geotextile filter is not needed. Moreover, the use of a drainage pipe wrapped in geotextile, justified on the clean water-saturated gravel and coarse sand and fractured rock watered soils without content of clay particles. On clay, loam soils GT trumpet can silted up over time (kolmatirovatsya) rendering a drainage failure and lead to the need to rework it.

Also for devices drainage wells are often used plastic pipes with large diameter pipes to connect the drains.

Among their advantages can distinguish light weight, long life, a large number of connectors, speed and ease of installation. The main disadvantage - the high price. Therefore, everyone decides for themselves what to choose.

Another "secret": the cover (bottom and top) reversed the user, because the inner surface of the cover intended for the top - is smooth, and the bottom has reinforcement ribs. If you have to clean the well, then collect the sand with such a surface will be more difficult. Yes, and cover design eye-catching.

Drainage wells: species

Drain well - an element of the drainage system, intended for its normal functioning, as well as monitoring and cleaning of drainage pipes. Drain well (in the presence of water-absorbent soil) is used as a filter, and the absorption of the well. Or (if the soil has a weak water absorption) is the intake. Based on this definition, drainage wells can be divided into the following types:

Rotary and inspection.

Absorption (filter).

Water inlet (cumulative).

Consider drainage wells each type in more detail.

Rotary shafts are installed in places turn drains (drains). This can be a corner of the foundation, elevation changes, convergence node multiple drains or places most susceptible to clog. A manhole is performed visual inspection and subsequent access to clean drains. Inspection and rotary shafts provided with a sealed bottom and a lid.

Razmer wells is chosen so that, if necessary could carry drainage water flushing pressure molding. The diameter of such wells ≈ 300 to 500 mm. If it is assumed that access to the system should go down the drain well people, the well diameter is increased to 1 meter or more.

Manholes are installed in the ground turns drains when changing the slope and Elevations.

The optimal distance between manholes on straight sections - 40 m, the maximum distance - 50 meters. By turning the drains in the projections of buildings manhole can not do, if the distance from the pivot to the nearest manhole no more than 20 meters. If the section between manholes drainage pipes made several turns, then the wells are mounted by 1 turn.

The choice of the filter (absorption) of the well caused the type of soil on the site. Purpose of this well the name implies - the water received by the drain of a well, is going in the receiver is filtered (eg, through the gravel layer) and through the holes, or if the well has no bottom, goes into the lower soil layers. Those. the soil should have sufficient water absorption capacity to cope with the volume of water flowing into the well. Thus ground, for example, can be coarse sand. Otherwise, the presence of water pressure, the water received by the water well, will not be able to escape into the soil, and the well will overflow with time.

Cumulative sealed wells are used in areas with high ground water table, clay soil and the ground, not having a high water absorption capacity. And in areas with deep water inlet layers doburitsya to whom and to arrange a vertical drainage is economically disadvantageous.

This well is the ultimate reservoir of the drainage system.

To the extent that the collected water is pumped out and the drain pump is reset for the plot border to the nearby ditch or used for irrigation.

Therefore, before you start the construction of drainage, it is necessary to produce a hydrogeological study of the soil and determine its composition and the ability of water absorption. Without these data, drainage construction - the construction blindly without understanding the essence of the processes occurring in the soil

. The easiest way "by eye» check the ability of the soil to water absorption - to dig a shallow hole at the site, pour water into it and see how fast it will go. If the water goes away slowly or does not go away, you should think about it, and where it is going to go away, if you build a filter drain well. Trying to "dig" to the plenum layer, without the knowledge of the geology of a particular area, it may be doomed to failure.

And in the area and water (effluent) can be quite different, with a different level of occurrence. It - surface water - livnёvka, derived from snowmelt and rain, perched - one of the types of groundwater, etc. Those. drainage - is not simply divert water. We need to know what kind of water you need to take.

What do drain well, and how to mount the drainage system

This is a question often asked by novice developers. The construction market offers two main options - buy a ready drain well of plastic or make drainage wells from RC rings. Both options have both pluses and minuses.

In this case, as a drainage well may be used with the RC ring sealed bottom. Rotary and manholes - alternatively, plastic, too, with a sealed bottom. Diameter - 40 cm Slop part in all wells -.. At least 30 cm

With a high groundwater table problem may be the installation of concrete manhole bases, as when digging water quickly arrives and floods and trench drains and a place where a pit is dug under the ring. In this case, you must first perform a dewatering. To do this, in the course of the track, made drains and digging pits, from which water is pumped out forcibly. After that, the installation of drainage wells and laying drains.

Holes for drainage pipes in the concrete ring can be cut without the use of a special crown.

This is done so - is marked hole of the required diameter, around the perimeter of the drilled through holes, and then the circle knocked

.

For the manufacture of such rings need flat ground, 2 pieces of sheet metal not less than 0.8 mm thick (the same width but different dina). The wire reinforcement (steel mesh can be used), to prepare a concrete mixer samomesnogo concrete and simple device for fixation of the formwork.

It is also important to make a very draining.

According to its users - this scheme is a classic radial drainage. For the calculation of the drainage should be noted that the depth of the drain depends on the type of underground structure, which is given water + soil Cp (Cp - coefficient of filtration, it characterizes the permeability of the soil) + the type and level of underground water and water pressure

Next, we add to the lowest mark of the pipe, a member of the central accumulation well, deepening the bottom for regulating the pump capacity. It is possible to calculate how many rings need.

The length of each beam drains - up to 40 meters. At the end of each beam bury a sealed chamber for washing. For example, of concrete rings. Slopes - drop marks be within 0.005 (for example, 40 meters x 0.005 = 0.2 m at the bottom)

. Drains conclude in a two- or three-layer sprinkled - the so-called inverse filter. This dusting, depending on the composition of the soil, can be made of crushed granite (the estimated fraction) and the coarse sand on the principle that we maintain a consistent transition from the pipe fractions (the largest) to fraction (finer) drained soil

.

When drainage device should be remembered that the traditional geotextile (GT), which is wrapped in a pipe with gravel and which is put on the tube is not a back-flow filter element. This is a necessary measure required to separate the layers. Those. HT is needed to prevent mixing of the layers, which allows us to simplify the selection of a reverse filter components because of the paucity of choice fractions (gravel, sand), presented in the construction market.

The right way to do the reverse geotextile filter is not needed. Moreover, the use of a drainage pipe wrapped in geotextile, justified on the clean water-saturated gravel and coarse sand and fractured rock watered soils without content of clay particles. On clay, loam soils GT trumpet can silted up over time (kolmatirovatsya) rendering a drainage failure and lead to the need to rework it.

Also for devices drainage wells are often used plastic pipes with large diameter pipes to connect the drains.

Among their advantages can distinguish light weight, long life, a large number of connectors, speed and ease of installation. The main disadvantage - the high price. Therefore, everyone decides for themselves what to choose.

Another "secret": the cover (bottom and top) reversed the user, because the inner surface of the cover intended for the top - is smooth, and the bottom has reinforcement ribs. If you have to clean the well, then collect the sand with such a surface will be more difficult. Yes, and cover design eye-catching.

"Streaming" electric car Quant F issued a record current

Unique rehabilitation techniques: exercises and techniques of acupressure massage