836

American engineers have gained a strong and transparent material to replace glass

As the glass, only better i>

Engineers from the US Navy Research Laboratory разработали manufacturing process durable and inexpensive glass replacement. The transparent material is made by means of low-temperature спекания of artificially produced crystals of spinel.

Spinel - is a mixed oxide of magnesium and aluminum, a mineral found in nature. In its natural form, it can be of different colors. For example, red spinel is indistinguishable to the eye from ruby, so before these two minerals are confused with each other. One of the famous jewels of the British Crown, Рубин Black Prince , actually - spinel.

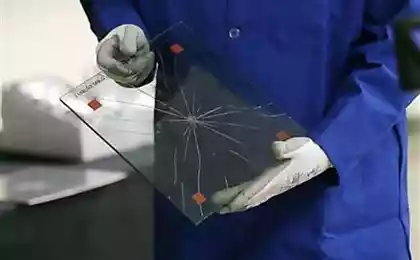

This material is very hard, it is able to resist impact and abrasion resistance when exposed to rain, salt water or sand. In addition, it transmits the infrared ray so may be useful in the manufacture of various devices. Unlike glass, the material does not crack over the entire surface - instead, on impact of it just breaks off a small piece. The final product can be polished and grind.

Hot Press i>

Previously, engineers attempted to obtain this material using high temperatures (2000 degrees or more). But this process was both expensive because of the energy costs, and ineffective - the need to separate the finished material from the surface of the crucible leads to the appearance of defects. During sintering using hot press, which makes the final polycrystalline powder blank product.

Attempts to produce large panels made of sintered spinel before. However, the material produced was cloudy, with small islands of transparency. Engineers managed to improve the quality of the product, adding a raw material of about 1% фторида Lithium , which melted, works as a lubricant and allows the spinel crystals are building each other.

article can be given any shape i>

Raw materials for manufacture are available in abundance, making the minimum cost price of products. Due to the simplicity of the technology of the material may make the products of any shape. Features extensive use: curved windows (eg, portholes for aircraft), lenses for appliances, glass clock, the screens of smartphones (stronger than gorilla glass ), camera lenses and binoculars. The military are interested in using this material as a transparent armor - compared to modern bullet-proof glasses weight of the finished product will be at least 2 times less.

Source: geektimes.ru/post/249766/

AT & T old man billed $ 24,298 for dialup

Stephen Hawking urges humanity to colonize other planets to survive