1355

Simplifying life counterparts

Hello, today I would like to tell you how using a minimum of knowledge can greatly simplify the lives of his colleagues.

It's about microscope monitor output, with some measuring bonuses.

Since first version was of little, and the second inaccurate, the idea of the third version.

First, describe the problem you it may seem petty, but it spoils people's lives.

Surely you know that OTC - a department of technical control, and as a consequence they check all the outputs. It seems everything is just wrong and you say, in addition to a large store of knowledge they require manual work and a partition.

If the item is large, then inspect it for defects is easy, but what if the item is 7 millimeters in diameter and hundreds of them?

At first I tried to make the optical system and the guide itself, but came crap (how and why the link above, for bulk material). It worked, but backlash and beats due to manual reduced production of all the pros at no.

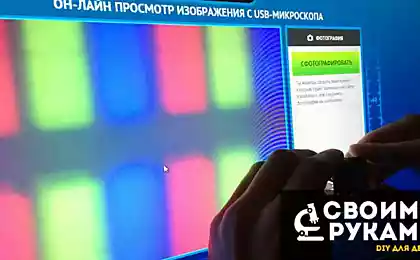

Therefore, I decided to use a microscope ready, as it has an optical system and focus, it remains only a wide adhesive tape (duct tape was not canonical) primotat camera to the eyepiece. Parallel to the development of software went for linear measurements directly on the screen. ( used Processing )

That's my darling, let's see what he sees (unfortunately only had the camera with a resolution of 640x480).

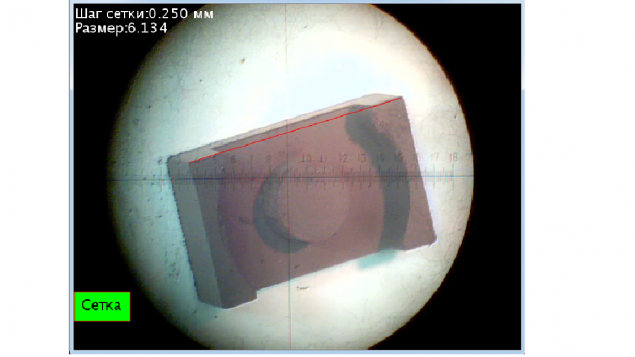

As you can see, sharpness, contrast and color range is quite perceptible. Here you can see elements of the measurement (step size) and display elements (mesh), but first things first.

Get the picture on the screen is not difficult , but it does not give enough information about the size of the observed object. The first idea was to make a measurement grid, ie put the object and once you see its size.

Grid had to "believe", using a straight tile thickness of 0.5 mm, puts it under a microscope and customize grid size, it was found that 0.5 mm is 26 pixels.

But sometimes it is not very convenient, so was introduced button to turn on \ off the grid display. But this, too little, because the operator does not always need a fine mesh, therefore, the possibility of scaling grid.

But this, too little, because the operator must be very precise to enclose the sample under the net, doing the work very accurately, it is tiring.

Yield showed "a direct measurement of the mouse," that is, the operator clicks on the screen in two places and is calculated length of this segment transferred from pixels to millimeters.

The accuracy of this method on 20 samples compared with the electronic caliper and micrometer was about 0.1 mm, which is quite satisfied with TCI.

As a result, all of suit, but was a little uncomfortable moment-screenshots. Each time pressing Alt + PrintScreen, and then save uncomfortable. It was therefore possible to save the image bolted window with the name of each file by date, for example Probe12 \ 10 \ 2014.jpg.

It was the final model, which is operated.

Finally some photos. (If you want to write more)

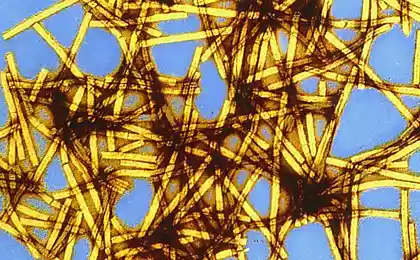

This pyroceramics ferrite rod coated with titanium by cathode sputtering in a vacuum chamber, again as in the image boundary transition materials.

This granular ferrite.

Well, actually he code . (Comments minimum if nuzhny- write)

Ready exe (x64, you need Java, JRE)

I apologize for the quality of photos and errors in the text.

Source: geektimes.ru/post/245104/

iPod from the '80s. Browse popular audio previous

Fima Baytler: "To inspire myself - not an easy task"