1814

How to make tractors: Minsk Wheel Tractor Plant

Plant of the number of those with high tribunes cited as the flagships of the Belarusian industry. "Family silver" - so accurately. Minsk Wheel Tractor Plant provides important defense orders for the armies of Russia and Belarus, so the strategic interests of our best friends, neighbors. Not that company closed, but there just is not there. This year marks the 60th anniversary MZKT.

MZKT was founded in July 1954 and has long functioned as a Special Bureau of Minsk Automobile Plant on heavy wheeled artillery tractors and engines. In 1991, the reorganization took place. Soon technique began to produce under the brand Volat. In 2010, the UE "Minsk Wheel Tractor Plant" has become a public company. The plant is part of the State Military-Industrial Committee. 100% of the shares (at the moment) belongs to Belarus.

This is a great company, a city in the city, with more than 5 thousand. Employees, excluding subsidiaries. Here are 10 production plants, 25 departments, 10 departments. Schematically, the production cycle is as follows: marketing research, development of technical specifications for the designer, designing, manufacturing machine, its testing and subsequent refinement. We are told that in Soviet times, the chain took an average of 5 years, but now the pace does not cook porridge. The customer will not wait. The actual period from concept to assembly line - up to 1 year civil engineering and from 2 to 3 years of military technology, there stricter standards. Factory warranty on "defense", by the way, is 10 years.

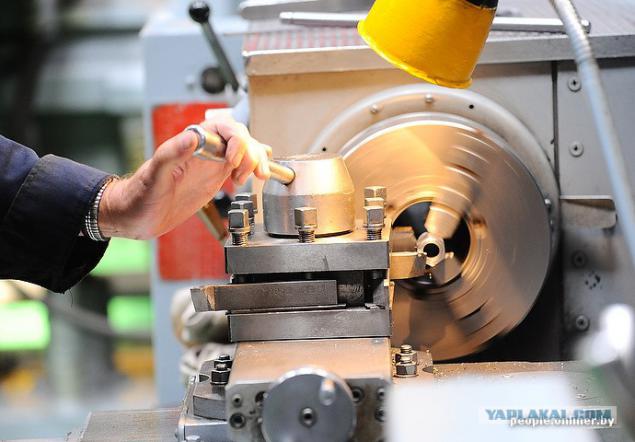

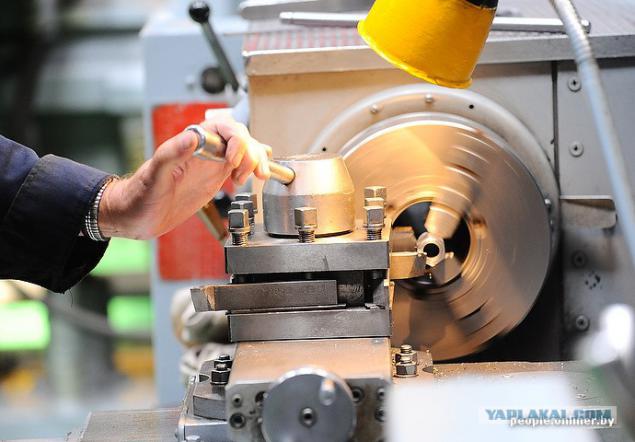

Journalists are in the research center. Here, all tested components and units that are used in the following production reducers, transmission, brakes, and so on. "In order to test even the smallest detail, it is necessary to make a special stand, - says head of department. - Much of the equipment was put back in the Soviet times. Using the manufacturer's conduct its modernization, in particular - the software. "

04

05

06

07

Water for employees - «Made in Belarus». Free.

At the site near the center - corner of history. Posted machines created in the early periods of work - to know the origins of young employees. Among other things - and the unique tractor for intercontinental missile complex "Celina-2" with 12 osnym chassis and electric transmission. Adopted the chassis is not accepted due to high cost, and "electric" theme for many years stalled. Now leaders say the school is lost, but there are plans to revive it. Subject promising because, despite the fact that the market is not quite ready.

10

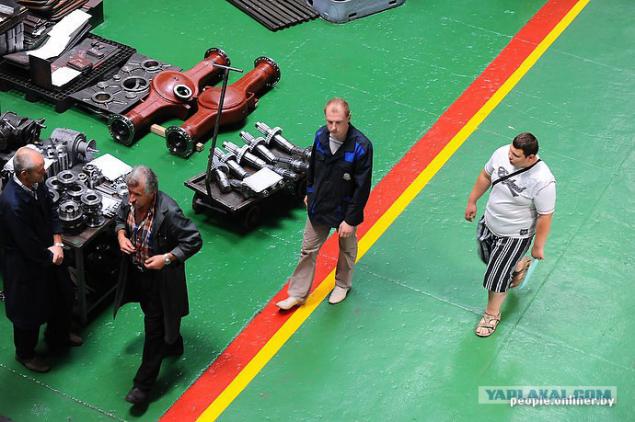

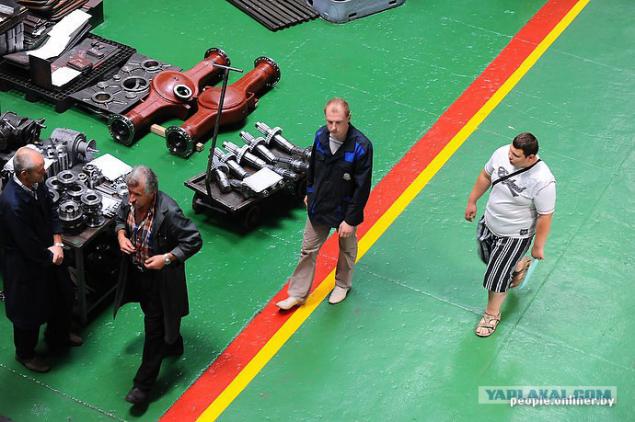

Components and assemblies are cut, grind out, bent, punched in the various workshops, and after they occur on the assembly line. We are in a huge hangar where all the new developments in the metal. For workplaces clean and tidy. Recently, there are many important guests, including "merchants" of Russia. In the lens gets a couple of frivolous calendars - the company has a lot of young people.

12

According to the director Vitaly Vovk, the average salary for MZKT is the highest in the industry and is 8.5 million rubles. Vovk at the same time makes it clear that not a fan of these statistics: they are not always objective. This is the average temperature in the hospital.

- Now we can select workers. On the whole, you know, the car market falls. Large-scale production is difficult to stop such companies may experience difficulties. We work targeted to your niche. Those professionals who want to make money, we have the opportunity - and the masters and designers.

Head MZKT

14

15

16

17

18

Go ahead. Models of wood, from which then will produce components for machines for producing Italian equipment. Previously it was done by hand. For the manufacture of tooling for the cab took 3-6 months, now - 2 weeks.

Cast cab (left)

Frame-press shop. Laser cutting of metal.

The biggest, experts say, listogib in the country.

Information on the board to get a grasp of "quality objectives for 2014": to develop at least eight new models provide profitability 12, 8%, to reach the volume of products sold in 1, 9 trillion rubles. The old Soviet tradition - one for all and all for one. Works?

24

25

26

27

28

29

30

31

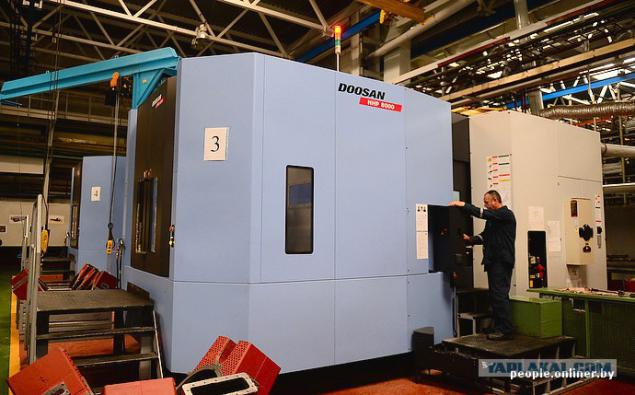

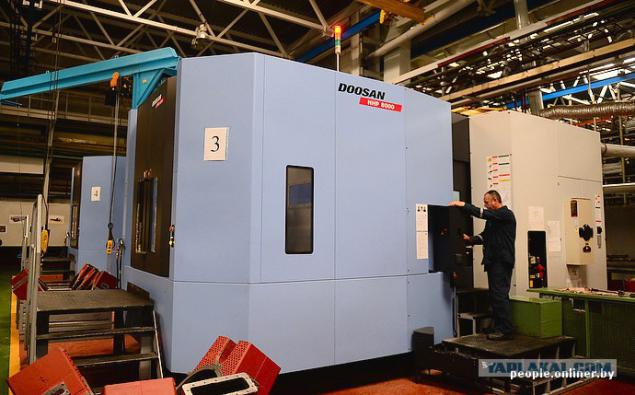

Workshop of flexible production systems. At the time, was perhaps the most advanced in the USSR. Now, says the guide, a prototype of the modern factory, how it would like to see. Here installed expensive equipment for complex machining. Process automation control system, a person controls. Looks like this site does not in Belarusian solid.

33

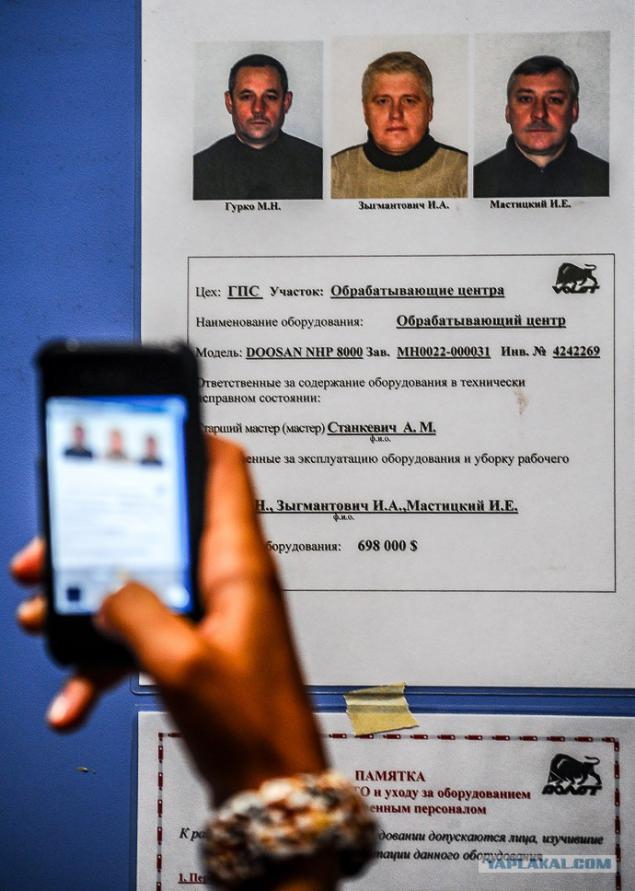

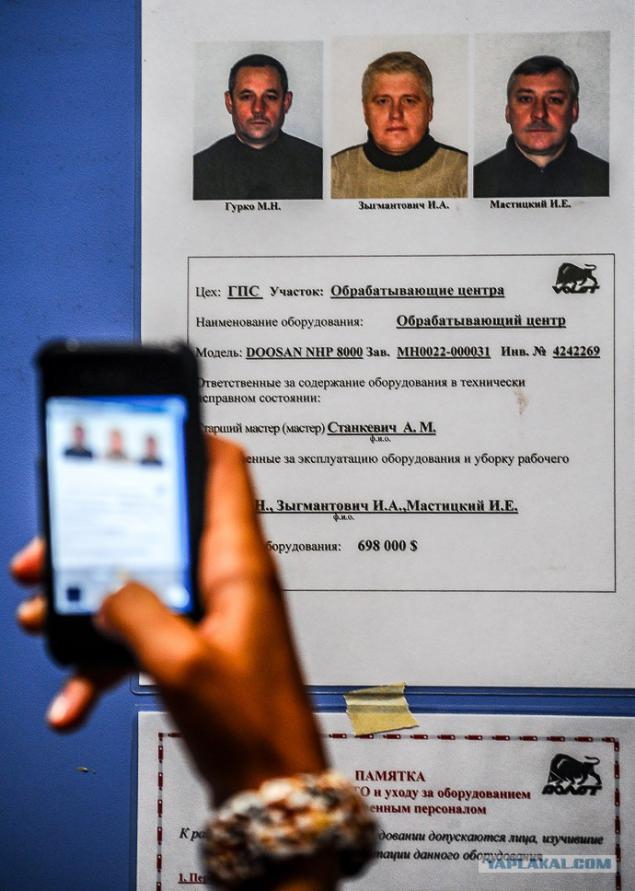

On each machine, plate: the names assigned workers and equipment costs. $ 698,000, € 535,000 ... This practice, experts say, is used in the West. In some ways, the motivation for employees.

35

36

37

Test and calibration point: check the settings made here parts.

Quite a regular unit. "Wow someone to catch mice" - jokes director.

The forefront of the plant - the assembly shop.

41

42

43

44

45

46

Originally MZKT produced exclusively military equipment. Now the proportion is as follows: 60% for the needs of the Armed Forces, 40% to the national economy. Up to 90% of production is exported. In the first place - to the CIS countries. The lion's share - in Russia. He has also worked with the markets of China, Turkey, Venezuela, Egypt, Pakistan, the United Arab Emirates. There are attempts to go to Latin America, but there is not that much.

MZKT mounted on the chassis and continue to put anti-aircraft missile systems S-300, multiple launch rocket systems "Smerch" tactical "Iskander" launchers "Topol-M" and more dangerous weapon. Civil Applications - mixers, tankers, cleaning and trucks, forestry equipment, and so on.

49

50

51

On the areas MZKT collect armored "Tiger" production Arzamas Engineering Plant. At the demonstration test-drive driver "Tiger" risk did not - the deepest pit neatly traveled.

Chassis for transporting the rig made to order oil. The engine is from Caterpillar - such was the demand of the customer. Engines, by the way, on the MZKT not produce, as well as details of electrics, tires. They were purchased from Belarusian and foreign companies.

The specificity of the plant, experts explain, and that do not work here at the warehouse - all machines are made to order.

- The technique is very expensive to do it for storage, - said the director. - Each chassis is different from each other, each made for a specific customer. If he can not at the moment take the technique, it is left for safekeeping. But it has already been paid, the money arrived.

- The principle of operation is as follows: Check with the customer, what technology he needs, and do it under the car - says chief engineer Andrew Golovach. - After the exhibition Milex approached the chief of staff, shows that need such a thing, but to also swim. No question! We have the resources. Now make a new chassis for new types of missile technology RF. As you know, can not be called parts. In Belarus, on behalf of the president developed an armored car. Make armored corps are not able, in the country do not produce armor. But everything else - please. Now the car on the run-in Special Operations Forces.

A special car "Fox" has already demonstrated at the recent military exhibition in the capital. This equipment is installed on the roof of the panoramic sight of the platform type and controlled antitank system "Hornet".

The chassis for the new solid-Russian intercontinental ballistic missile "yars" - a modernized missile complex "Topol-M". The unique thing, we are told, no one else does this.

Among the exclusive development, which is proud of - 38-meter tankovoz- "caterpillar". And this is - the car more mundane, for the needs of border guards.

So far, however, the Minsk Wheel Tractor Plant think not so much about new products, but about the future.

- Be able to find reliable information about the sale MZKT? Familiar workers say they have already sold "Russian Technologies" and began to guide me - a letter came the other day in our editorial.

The question we have readdressed CEO:

- You're still the Belarusian company?

- Do you doubt?

A little later, Vitaliy Vovk added: "Our main task - to find a strategic investor and, therefore, cheap funds for modernization that our banks are not able to offer».

It would seem that everything is already decided long ago. Late last year, it was reported that an agreement was reached on the sale of shares MZKT (75% minus 1 share) Russian JSC "RT-Auto" - unit "Russian Technologies". Required only to hold an honest assessment of the company's assets at market price. According to Vitaly Vovk, the procedure is nearing completion. Soon to be available specific figures. The general director said that the transaction must be protected and the interests of the company, its employees and the country. This was recently spoke and Deputy Prime Minister Semashko. Sale of "silver" is inevitable, but it will bargain for zealously, for every ruble.

58

Last spring

MZKT was founded in July 1954 and has long functioned as a Special Bureau of Minsk Automobile Plant on heavy wheeled artillery tractors and engines. In 1991, the reorganization took place. Soon technique began to produce under the brand Volat. In 2010, the UE "Minsk Wheel Tractor Plant" has become a public company. The plant is part of the State Military-Industrial Committee. 100% of the shares (at the moment) belongs to Belarus.

This is a great company, a city in the city, with more than 5 thousand. Employees, excluding subsidiaries. Here are 10 production plants, 25 departments, 10 departments. Schematically, the production cycle is as follows: marketing research, development of technical specifications for the designer, designing, manufacturing machine, its testing and subsequent refinement. We are told that in Soviet times, the chain took an average of 5 years, but now the pace does not cook porridge. The customer will not wait. The actual period from concept to assembly line - up to 1 year civil engineering and from 2 to 3 years of military technology, there stricter standards. Factory warranty on "defense", by the way, is 10 years.

Journalists are in the research center. Here, all tested components and units that are used in the following production reducers, transmission, brakes, and so on. "In order to test even the smallest detail, it is necessary to make a special stand, - says head of department. - Much of the equipment was put back in the Soviet times. Using the manufacturer's conduct its modernization, in particular - the software. "

04

05

06

07

Water for employees - «Made in Belarus». Free.

At the site near the center - corner of history. Posted machines created in the early periods of work - to know the origins of young employees. Among other things - and the unique tractor for intercontinental missile complex "Celina-2" with 12 osnym chassis and electric transmission. Adopted the chassis is not accepted due to high cost, and "electric" theme for many years stalled. Now leaders say the school is lost, but there are plans to revive it. Subject promising because, despite the fact that the market is not quite ready.

10

Components and assemblies are cut, grind out, bent, punched in the various workshops, and after they occur on the assembly line. We are in a huge hangar where all the new developments in the metal. For workplaces clean and tidy. Recently, there are many important guests, including "merchants" of Russia. In the lens gets a couple of frivolous calendars - the company has a lot of young people.

12

According to the director Vitaly Vovk, the average salary for MZKT is the highest in the industry and is 8.5 million rubles. Vovk at the same time makes it clear that not a fan of these statistics: they are not always objective. This is the average temperature in the hospital.

- Now we can select workers. On the whole, you know, the car market falls. Large-scale production is difficult to stop such companies may experience difficulties. We work targeted to your niche. Those professionals who want to make money, we have the opportunity - and the masters and designers.

Head MZKT

14

15

16

17

18

Go ahead. Models of wood, from which then will produce components for machines for producing Italian equipment. Previously it was done by hand. For the manufacture of tooling for the cab took 3-6 months, now - 2 weeks.

Cast cab (left)

Frame-press shop. Laser cutting of metal.

The biggest, experts say, listogib in the country.

Information on the board to get a grasp of "quality objectives for 2014": to develop at least eight new models provide profitability 12, 8%, to reach the volume of products sold in 1, 9 trillion rubles. The old Soviet tradition - one for all and all for one. Works?

24

25

26

27

28

29

30

31

Workshop of flexible production systems. At the time, was perhaps the most advanced in the USSR. Now, says the guide, a prototype of the modern factory, how it would like to see. Here installed expensive equipment for complex machining. Process automation control system, a person controls. Looks like this site does not in Belarusian solid.

33

On each machine, plate: the names assigned workers and equipment costs. $ 698,000, € 535,000 ... This practice, experts say, is used in the West. In some ways, the motivation for employees.

35

36

37

Test and calibration point: check the settings made here parts.

Quite a regular unit. "Wow someone to catch mice" - jokes director.

The forefront of the plant - the assembly shop.

41

42

43

44

45

46

Originally MZKT produced exclusively military equipment. Now the proportion is as follows: 60% for the needs of the Armed Forces, 40% to the national economy. Up to 90% of production is exported. In the first place - to the CIS countries. The lion's share - in Russia. He has also worked with the markets of China, Turkey, Venezuela, Egypt, Pakistan, the United Arab Emirates. There are attempts to go to Latin America, but there is not that much.

MZKT mounted on the chassis and continue to put anti-aircraft missile systems S-300, multiple launch rocket systems "Smerch" tactical "Iskander" launchers "Topol-M" and more dangerous weapon. Civil Applications - mixers, tankers, cleaning and trucks, forestry equipment, and so on.

49

50

51

On the areas MZKT collect armored "Tiger" production Arzamas Engineering Plant. At the demonstration test-drive driver "Tiger" risk did not - the deepest pit neatly traveled.

Chassis for transporting the rig made to order oil. The engine is from Caterpillar - such was the demand of the customer. Engines, by the way, on the MZKT not produce, as well as details of electrics, tires. They were purchased from Belarusian and foreign companies.

The specificity of the plant, experts explain, and that do not work here at the warehouse - all machines are made to order.

- The technique is very expensive to do it for storage, - said the director. - Each chassis is different from each other, each made for a specific customer. If he can not at the moment take the technique, it is left for safekeeping. But it has already been paid, the money arrived.

- The principle of operation is as follows: Check with the customer, what technology he needs, and do it under the car - says chief engineer Andrew Golovach. - After the exhibition Milex approached the chief of staff, shows that need such a thing, but to also swim. No question! We have the resources. Now make a new chassis for new types of missile technology RF. As you know, can not be called parts. In Belarus, on behalf of the president developed an armored car. Make armored corps are not able, in the country do not produce armor. But everything else - please. Now the car on the run-in Special Operations Forces.

A special car "Fox" has already demonstrated at the recent military exhibition in the capital. This equipment is installed on the roof of the panoramic sight of the platform type and controlled antitank system "Hornet".

The chassis for the new solid-Russian intercontinental ballistic missile "yars" - a modernized missile complex "Topol-M". The unique thing, we are told, no one else does this.

Among the exclusive development, which is proud of - 38-meter tankovoz- "caterpillar". And this is - the car more mundane, for the needs of border guards.

So far, however, the Minsk Wheel Tractor Plant think not so much about new products, but about the future.

- Be able to find reliable information about the sale MZKT? Familiar workers say they have already sold "Russian Technologies" and began to guide me - a letter came the other day in our editorial.

The question we have readdressed CEO:

- You're still the Belarusian company?

- Do you doubt?

A little later, Vitaliy Vovk added: "Our main task - to find a strategic investor and, therefore, cheap funds for modernization that our banks are not able to offer».

It would seem that everything is already decided long ago. Late last year, it was reported that an agreement was reached on the sale of shares MZKT (75% minus 1 share) Russian JSC "RT-Auto" - unit "Russian Technologies". Required only to hold an honest assessment of the company's assets at market price. According to Vitaly Vovk, the procedure is nearing completion. Soon to be available specific figures. The general director said that the transaction must be protected and the interests of the company, its employees and the country. This was recently spoke and Deputy Prime Minister Semashko. Sale of "silver" is inevitable, but it will bargain for zealously, for every ruble.

58

Last spring