1306

The domestic auto industry - Volvo Trucks

67 photo + letter

via zizis

In January 2009, in Kaluga was opened a new plant for the production of Volvo trucks. The first factory was opened in 2003 in Zelenograd, but due to lack of power production was moved to a new area near Kaluga.

01.

In Kaluga, it is not just a factory, and the whole complex, including both production and installation of additional equipment, and a service center and office part, where customers come for the conclusion of contracts.

02.

The entire complex of 55 hectares was built in record time. From the laying of the first stone to the start of production it took only 14 months. Now the annual production capacity to produce 15,000 trucks a year.

03.

Volvo Truck Corporation is the second largest global branded truck manufacturers. In the same corporation includes Renault Trucks, Nissan Diesel and Mack Truck. Volvo trucks are perfectly familiar to the whole territory of the former USSR. Back in 1973, zaklyuchika contract to supply "Sovtransavto" 100 tractors. And now, it is Volvo cars are the leaders of the commercial trucks in Russia. Every fourth truck - Volvo. All cars produced at the plant in Kaluga, have the status of domestic products. Here such here it is, the domestic auto industry.

04.

Like any cult brand, Volvo produces its own line of clothing, accessories and even toys. Every three years, conducting ocean regatta sailing yacht Volvo Ocean Race (Volvo in addition to trucks and buses produces construction equipment, marine engines and the system even components for space systems).

05.

And for more than 13 years, Russia has a training school of Volvo's engineers and drivers. Of course it is not a driving school to open freight categories. There comes to professional drivers training. Correctly plan a trip, calculate the amount of fuel, right to select an average speed, and more. This flight is going well and, therefore, savings for the client.

06.

In Kaluga produced medium-duty trucks. The main types of this career FMX trucks and tractors FM and FH.

07.

The company's policy is that trucks are not built in reserve. Each machine is going for a particular client, taking into account his wishes and requirements. On the chassis set certified equipment from leading manufacturers.

08.

The average of the contract until the customer takes the car a couple of months. Order, of course, not one car, but several dozen. The plant operates with the client directly, thereby eliminating middlemen and prices cheat the customer gets exactly what he wants.

09.

Small regional tractor FM - bestseller in Russia, and they are still doing with a small margin. Anyway fly like hotcakes.

10.

Here the plant itself (right), an office building (left) and a playground for the finished product. It looks like a small building, but every day of it can go more than 40 trucks of different assembly. See trailers in the queue for unloading? It arrived parts for assembly.

11.

Engines, transmissions, cabs come in the form of a semi-assembled. For example, the engines arrived from his native city for the Volvo Sko "vde, a cab come from factories in Sweden and Belgium. Road train arrives at the plant, leaves and takes full trailer empty. And then he goes to the return flight.

12.

I do not know how other car factories, and here before the birth of the car know exactly the number of its frame, engine and equipment. Here's the engine was brought thousands of kilometers to make up a whole with this box.

Photo removed at the request 13.

Here once filled the right oil. For the conditions of the north one for the other central Russia, and for the third mining equipment.

14.

For each set of your engine. After assembling the trolley should remain empty, "savings" components excluded.

15.

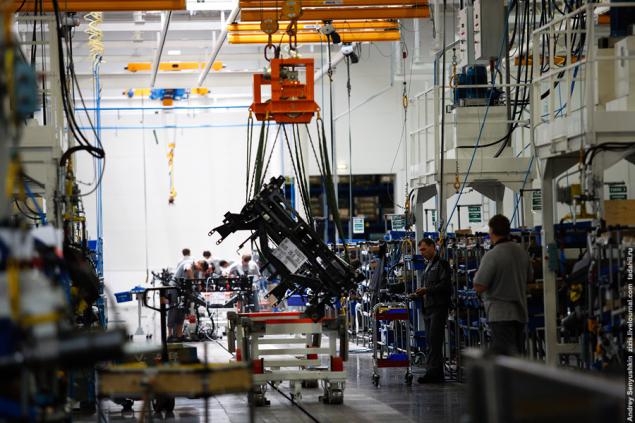

On the other end of the shop is a conveyor assembly chassis. We were lucky, the thousand.

16.

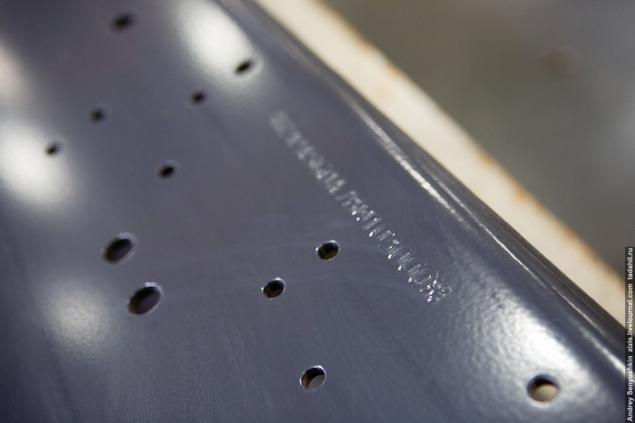

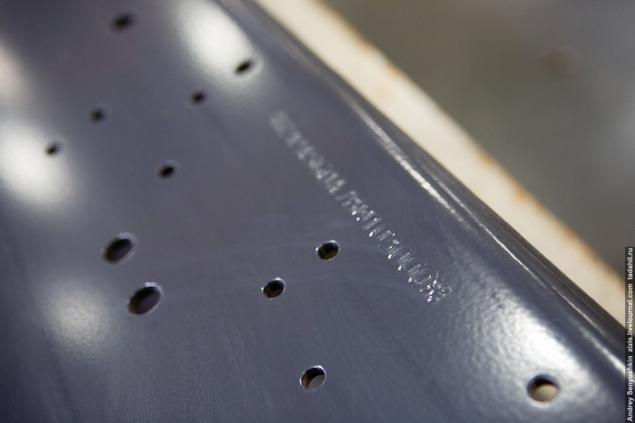

Volvo is one of the few brands still bolted together using the riveting. This is much stronger, more flexible and easier to bolting. The only serious drawback - maintainability. Bolt can be changed in any circumstances, and will have to drill riveting and rivet again.

17.

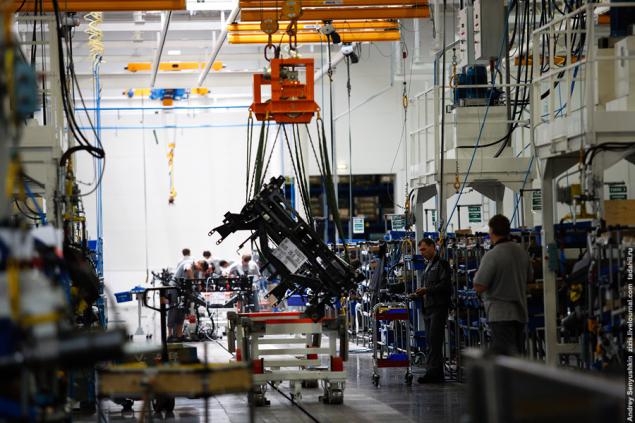

This is not a cunning mechanism turns the frame. At the initial stage it is convenient to collect upside down, and then normal.

18.

The plant is one of the largest companies in the region, making a considerable contribution to the budget, and supports a number of social programs. Even children are organized hockey tournament for the Cup of Volvo.

19.

In parallel with frames collected bridges and suspension components.

20.

Please note, although this conveyor, but they are all different.

21.

All parts come here in these boxes. It is difficult to imagine how many times the container crossing the border.

22.

From a warehouse (it is in the same room) boxes are brought on these forklift trucks. A smaller parts were conveyed little road train with a few carriages, carts.

23.

Warehouse - a multilevel structure. All the boxes marked tags with bar codes, so everything is in its place and not lost

24.

The fact that smaller - lower. On the territory of the assembly shop in the same area there is a small, temporary warehouses. There parts are stored, used during a work shift.

25.

Today Volvo in Kaluga plant is the latest venture of the Volvo Trucks plant in the world.

26.

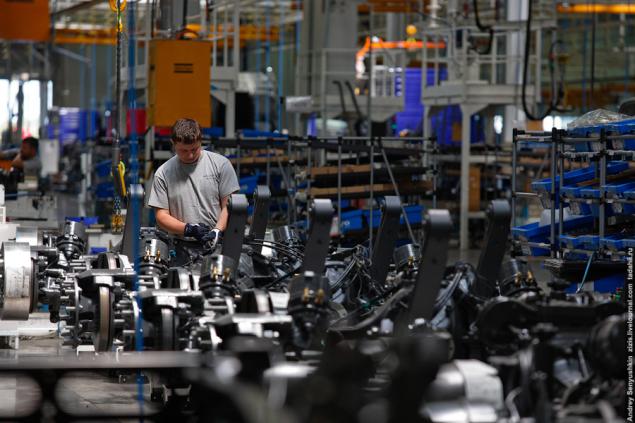

Here are used the most advanced technology. Do not forget about the working conditions.

27.

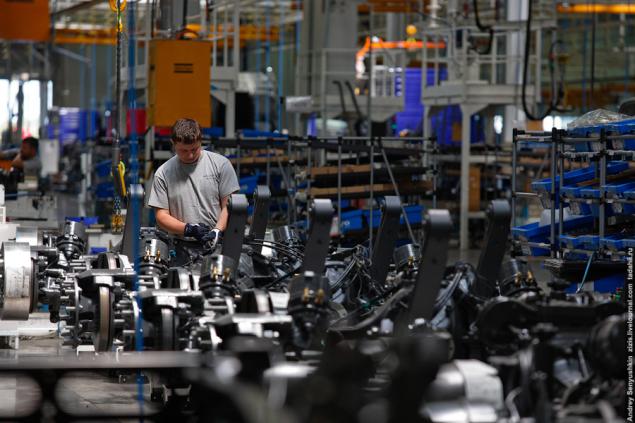

One of the most important and time-consuming process of creating a vehicle is installed on the frame of the suspension.

28.

In this operation, a lot of points, so the people on this point too much.

29.

The work is almost never used hand tools. This is mainly Pneumatic. Moreover, each is checked regularly for compliance and if there is even the slightest suspicion of a malfunction, immediately sent in for repair.

30.

So you can be sure that the same hardware in different instances of the same car tightened the moment and meet the technical requirements.

31.

The lower part of the car, if you can call it certainly is collected. Let's see how to collect the cockpit. Here is the assembly and testing of head light.

Interesting fact. To reduce the cost of service in 2010, Volvo has not a single lamp unit, as it was before, and the individual components. If the truck is broken fog, which is not uncommon, it is enough to replace the fog, not the entire unit as a whole. The logic is not clear for cars manufacturers that if they gave them the will to produce cars at all beyond repair.

32.

Cabs come already painted. If during transport formed small chips, there are a camera for painting. To workers have access to all surfaces of the cabin, attached to its special manipulator by means of which it can be rotated in virtually any plane.

33.

Doors removed and hung on special brackets behind the cab. Sami cabin just move along a conveyer and are moved from point to point.

34.

While in the booth run the wiring, insulation, insulation, seats and put the panel back in the door set windows, locks and decorative panels.

35.

Well, tired? Not long left.

While all the elements of the future of the car pulled together into one assembly point, you can look at resting place teams. Throughout the workshop several. Here you can rest, read a bulletin board, find out the schedule of work, talk to the foreman. On all these points installed computers on which you can view information about the work done.

36.

Here are personal lockers with a tool. Each of them signed, this is a safe Babaevskie Squirrels.

37.

In the production of a lot of women. The plans to balance the sex ratio of one to one. Of course, not by reducing the male workers, and by expanding production.

38.

But back to the conveyor. He does not like to wait, and that we missed the moment of installation of the engine and had only tricky process of merging systems.

39.

A small digression. Despite the fact that during the shooting in the shop did not burn natural light, it turned out one of the brightest productions I've seen. The fact that the ceiling light boxes are in daytime illuminated whole shop ordinary sunlight. Especially beautiful it looks in the final assembly line.

40.

Each car has to accompany the birth of a whole dossier. Later he was to add the test results on the stand.

41.

And that's the most exciting seconds. Prior to that, the car has even assembled, mix of conveyer on special carts.

42.

And the first time he gets to the wheels.

43.

Immediately comes the first refueling.

44.

And then dressed with air conditioning and radiator coolant.

45.

In principle, all the car ready. Then already it moves under its own power in the pit for the final work. Yama is also computerized.

46.

It is similarity collapse.

47.

And the car is driven into a special room on a rolling machine. Test results are filed to the "business" and will be stored and the archive in paper and electronic form.

48.

That is now a small production do you think that's it? Of course not!

49.

A tasty snack in the canteen and go ahead!

50.

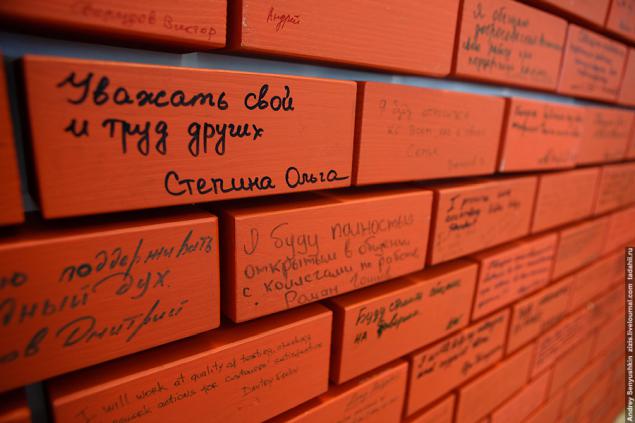

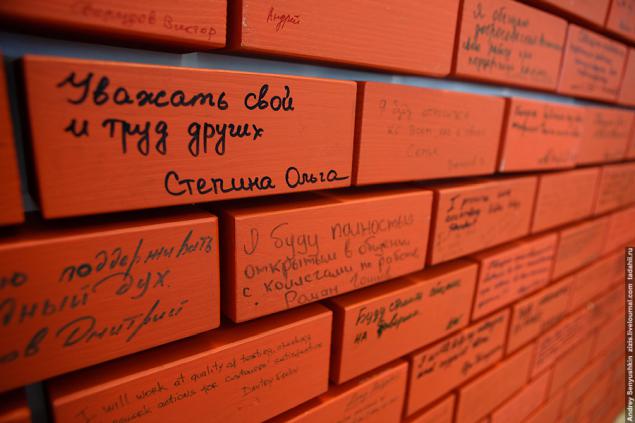

By the way, in the dining room is a wall on which the new employees at entry write their promises.

51.

Well, let's see what we got out of the factory gates. This dump truck FMX.

52.

In general, nothing special, a workhorse. There is a comfortable chair, music, air conditioning, good transmission. What else in the career you want?

53.

This long-haul tractor FH. Steeper has only flagship FH16 with production capacity of up to 700 horsepower. But he did not have produced, and the need for some very specific traffic. Even here the standard FH tractor-trailer can carry a weight of up to 100 tons.

54.

Inside is much more interesting than the dump truck. Even more comfortable chair, a leather steering wheel, communications via satellite, as many as six external side mirrors. Optionally, you can order a leather interior and alloy wheels. I am not kidding.

55.

Most of all I liked the automatic transmission. Very nice work, but it can be switched to manual mode and change gear end keys "±".

56.

Generally, the convenience and comfort of long-range tractors have long surpassed cars. Even doroguschy heaped jeep I was less convenient than driving this tractor. This is understandable - a professional tool should be comfortable and safe, and commercial freight it really is.

57.

And of course there is sleeping accommodation. Not the royal bed, but quite a comfortable bed.

58.

That comparison cabin twenty F10.

59.

Whatever the reliability of the machine have not been, but sooner or later break down. And then they come to the aid technicals, or if it is absolutely bad, here are tow. This machine is able to take to the service truck with a semitrailer.

60.

Or provide all possible assistance right on the highway.

61.

Here, finally, we got to the final point of our tour - the service shop. People come here to repair trucks from the road, here comes the installation of additional equipment on new cars, for example, to dump the body.

I really liked the room driver. While the car is undergoing maintenance, the driver can take a shower and take a nap on the comfortable sofa and watch TV.

62.

Unique. All multi-ton vehicle is raised by two huge hydraulic jacks. By the way, it made the first Volvo and zapantentovali cabover cab tilts forward and modern layout engine. Prior to that, all trucks were multimeter with hoods, and a similar arrangement is allowed to significantly reduce the length of the car.

63.

From under the truck was heard native speech without notes I finally passed an obsession and I was back in Russia, in the Kaluga region.

64.

Here the legendary F10 came with some problems with the rear axle. He was more than twenty years and mileage on estimates exceeded 4 million kilometers. 100 times around the Earth or six times to the moon and back ...

65.

There is also a very convenient wash truck. You can directly without leaving the warmth of boxing disengage, to wash, to mate and to go further.

66.

I was very impressed with this trip. To think seriously about the possibility of opening the cargo category and take a test drive a tractor. Even just a head without a semi-trailer, just go.

Buy a truck that's not even half the story. This is just the beginning. It is necessary to buy a good reliable truck, providing good network services. After all, these cars spend their entire lives in motion and bring profit to the owner. Any simple - loss.

You know what is translated from the Latin "volvo"? "I roll".

Posted in [mergetime] 1309378307 [/ mergetime]

everything ...

Source:

via zizis

In January 2009, in Kaluga was opened a new plant for the production of Volvo trucks. The first factory was opened in 2003 in Zelenograd, but due to lack of power production was moved to a new area near Kaluga.

01.

In Kaluga, it is not just a factory, and the whole complex, including both production and installation of additional equipment, and a service center and office part, where customers come for the conclusion of contracts.

02.

The entire complex of 55 hectares was built in record time. From the laying of the first stone to the start of production it took only 14 months. Now the annual production capacity to produce 15,000 trucks a year.

03.

Volvo Truck Corporation is the second largest global branded truck manufacturers. In the same corporation includes Renault Trucks, Nissan Diesel and Mack Truck. Volvo trucks are perfectly familiar to the whole territory of the former USSR. Back in 1973, zaklyuchika contract to supply "Sovtransavto" 100 tractors. And now, it is Volvo cars are the leaders of the commercial trucks in Russia. Every fourth truck - Volvo. All cars produced at the plant in Kaluga, have the status of domestic products. Here such here it is, the domestic auto industry.

04.

Like any cult brand, Volvo produces its own line of clothing, accessories and even toys. Every three years, conducting ocean regatta sailing yacht Volvo Ocean Race (Volvo in addition to trucks and buses produces construction equipment, marine engines and the system even components for space systems).

05.

And for more than 13 years, Russia has a training school of Volvo's engineers and drivers. Of course it is not a driving school to open freight categories. There comes to professional drivers training. Correctly plan a trip, calculate the amount of fuel, right to select an average speed, and more. This flight is going well and, therefore, savings for the client.

06.

In Kaluga produced medium-duty trucks. The main types of this career FMX trucks and tractors FM and FH.

07.

The company's policy is that trucks are not built in reserve. Each machine is going for a particular client, taking into account his wishes and requirements. On the chassis set certified equipment from leading manufacturers.

08.

The average of the contract until the customer takes the car a couple of months. Order, of course, not one car, but several dozen. The plant operates with the client directly, thereby eliminating middlemen and prices cheat the customer gets exactly what he wants.

09.

Small regional tractor FM - bestseller in Russia, and they are still doing with a small margin. Anyway fly like hotcakes.

10.

Here the plant itself (right), an office building (left) and a playground for the finished product. It looks like a small building, but every day of it can go more than 40 trucks of different assembly. See trailers in the queue for unloading? It arrived parts for assembly.

11.

Engines, transmissions, cabs come in the form of a semi-assembled. For example, the engines arrived from his native city for the Volvo Sko "vde, a cab come from factories in Sweden and Belgium. Road train arrives at the plant, leaves and takes full trailer empty. And then he goes to the return flight.

12.

I do not know how other car factories, and here before the birth of the car know exactly the number of its frame, engine and equipment. Here's the engine was brought thousands of kilometers to make up a whole with this box.

Photo removed at the request 13.

Here once filled the right oil. For the conditions of the north one for the other central Russia, and for the third mining equipment.

14.

For each set of your engine. After assembling the trolley should remain empty, "savings" components excluded.

15.

On the other end of the shop is a conveyor assembly chassis. We were lucky, the thousand.

16.

Volvo is one of the few brands still bolted together using the riveting. This is much stronger, more flexible and easier to bolting. The only serious drawback - maintainability. Bolt can be changed in any circumstances, and will have to drill riveting and rivet again.

17.

This is not a cunning mechanism turns the frame. At the initial stage it is convenient to collect upside down, and then normal.

18.

The plant is one of the largest companies in the region, making a considerable contribution to the budget, and supports a number of social programs. Even children are organized hockey tournament for the Cup of Volvo.

19.

In parallel with frames collected bridges and suspension components.

20.

Please note, although this conveyor, but they are all different.

21.

All parts come here in these boxes. It is difficult to imagine how many times the container crossing the border.

22.

From a warehouse (it is in the same room) boxes are brought on these forklift trucks. A smaller parts were conveyed little road train with a few carriages, carts.

23.

Warehouse - a multilevel structure. All the boxes marked tags with bar codes, so everything is in its place and not lost

24.

The fact that smaller - lower. On the territory of the assembly shop in the same area there is a small, temporary warehouses. There parts are stored, used during a work shift.

25.

Today Volvo in Kaluga plant is the latest venture of the Volvo Trucks plant in the world.

26.

Here are used the most advanced technology. Do not forget about the working conditions.

27.

One of the most important and time-consuming process of creating a vehicle is installed on the frame of the suspension.

28.

In this operation, a lot of points, so the people on this point too much.

29.

The work is almost never used hand tools. This is mainly Pneumatic. Moreover, each is checked regularly for compliance and if there is even the slightest suspicion of a malfunction, immediately sent in for repair.

30.

So you can be sure that the same hardware in different instances of the same car tightened the moment and meet the technical requirements.

31.

The lower part of the car, if you can call it certainly is collected. Let's see how to collect the cockpit. Here is the assembly and testing of head light.

Interesting fact. To reduce the cost of service in 2010, Volvo has not a single lamp unit, as it was before, and the individual components. If the truck is broken fog, which is not uncommon, it is enough to replace the fog, not the entire unit as a whole. The logic is not clear for cars manufacturers that if they gave them the will to produce cars at all beyond repair.

32.

Cabs come already painted. If during transport formed small chips, there are a camera for painting. To workers have access to all surfaces of the cabin, attached to its special manipulator by means of which it can be rotated in virtually any plane.

33.

Doors removed and hung on special brackets behind the cab. Sami cabin just move along a conveyer and are moved from point to point.

34.

While in the booth run the wiring, insulation, insulation, seats and put the panel back in the door set windows, locks and decorative panels.

35.

Well, tired? Not long left.

While all the elements of the future of the car pulled together into one assembly point, you can look at resting place teams. Throughout the workshop several. Here you can rest, read a bulletin board, find out the schedule of work, talk to the foreman. On all these points installed computers on which you can view information about the work done.

36.

Here are personal lockers with a tool. Each of them signed, this is a safe Babaevskie Squirrels.

37.

In the production of a lot of women. The plans to balance the sex ratio of one to one. Of course, not by reducing the male workers, and by expanding production.

38.

But back to the conveyor. He does not like to wait, and that we missed the moment of installation of the engine and had only tricky process of merging systems.

39.

A small digression. Despite the fact that during the shooting in the shop did not burn natural light, it turned out one of the brightest productions I've seen. The fact that the ceiling light boxes are in daytime illuminated whole shop ordinary sunlight. Especially beautiful it looks in the final assembly line.

40.

Each car has to accompany the birth of a whole dossier. Later he was to add the test results on the stand.

41.

And that's the most exciting seconds. Prior to that, the car has even assembled, mix of conveyer on special carts.

42.

And the first time he gets to the wheels.

43.

Immediately comes the first refueling.

44.

And then dressed with air conditioning and radiator coolant.

45.

In principle, all the car ready. Then already it moves under its own power in the pit for the final work. Yama is also computerized.

46.

It is similarity collapse.

47.

And the car is driven into a special room on a rolling machine. Test results are filed to the "business" and will be stored and the archive in paper and electronic form.

48.

That is now a small production do you think that's it? Of course not!

49.

A tasty snack in the canteen and go ahead!

50.

By the way, in the dining room is a wall on which the new employees at entry write their promises.

51.

Well, let's see what we got out of the factory gates. This dump truck FMX.

52.

In general, nothing special, a workhorse. There is a comfortable chair, music, air conditioning, good transmission. What else in the career you want?

53.

This long-haul tractor FH. Steeper has only flagship FH16 with production capacity of up to 700 horsepower. But he did not have produced, and the need for some very specific traffic. Even here the standard FH tractor-trailer can carry a weight of up to 100 tons.

54.

Inside is much more interesting than the dump truck. Even more comfortable chair, a leather steering wheel, communications via satellite, as many as six external side mirrors. Optionally, you can order a leather interior and alloy wheels. I am not kidding.

55.

Most of all I liked the automatic transmission. Very nice work, but it can be switched to manual mode and change gear end keys "±".

56.

Generally, the convenience and comfort of long-range tractors have long surpassed cars. Even doroguschy heaped jeep I was less convenient than driving this tractor. This is understandable - a professional tool should be comfortable and safe, and commercial freight it really is.

57.

And of course there is sleeping accommodation. Not the royal bed, but quite a comfortable bed.

58.

That comparison cabin twenty F10.

59.

Whatever the reliability of the machine have not been, but sooner or later break down. And then they come to the aid technicals, or if it is absolutely bad, here are tow. This machine is able to take to the service truck with a semitrailer.

60.

Or provide all possible assistance right on the highway.

61.

Here, finally, we got to the final point of our tour - the service shop. People come here to repair trucks from the road, here comes the installation of additional equipment on new cars, for example, to dump the body.

I really liked the room driver. While the car is undergoing maintenance, the driver can take a shower and take a nap on the comfortable sofa and watch TV.

62.

Unique. All multi-ton vehicle is raised by two huge hydraulic jacks. By the way, it made the first Volvo and zapantentovali cabover cab tilts forward and modern layout engine. Prior to that, all trucks were multimeter with hoods, and a similar arrangement is allowed to significantly reduce the length of the car.

63.

From under the truck was heard native speech without notes I finally passed an obsession and I was back in Russia, in the Kaluga region.

64.

Here the legendary F10 came with some problems with the rear axle. He was more than twenty years and mileage on estimates exceeded 4 million kilometers. 100 times around the Earth or six times to the moon and back ...

65.

There is also a very convenient wash truck. You can directly without leaving the warmth of boxing disengage, to wash, to mate and to go further.

66.

I was very impressed with this trip. To think seriously about the possibility of opening the cargo category and take a test drive a tractor. Even just a head without a semi-trailer, just go.

Buy a truck that's not even half the story. This is just the beginning. It is necessary to buy a good reliable truck, providing good network services. After all, these cars spend their entire lives in motion and bring profit to the owner. Any simple - loss.

You know what is translated from the Latin "volvo"? "I roll".

Posted in [mergetime] 1309378307 [/ mergetime]

everything ...

Source: