1644

Metalworking - 2014 or the story about Robots

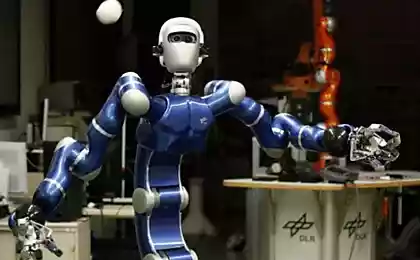

While in Artpley continues Ball robots (by the way, there is a stand MadRobots, you can go and see), in Expocentre little fanfare began and ended with an exhibition Metal-2014, which shows, IMHO, more interesting robots. How can you tell from the name, they were mostly industrial machines for metal. They certainly can not communicate with people, and often do only one operation, but like they do it!

I apologize in advance for up to 800 kilobytes gifyatiny kata. Then it will be worse.

Unfortunately, due to lack of time, I have been in only one of the pavilion 7, but there was a lot of fun.

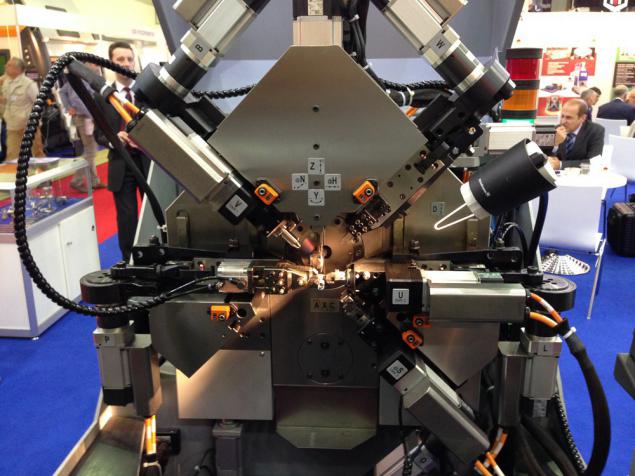

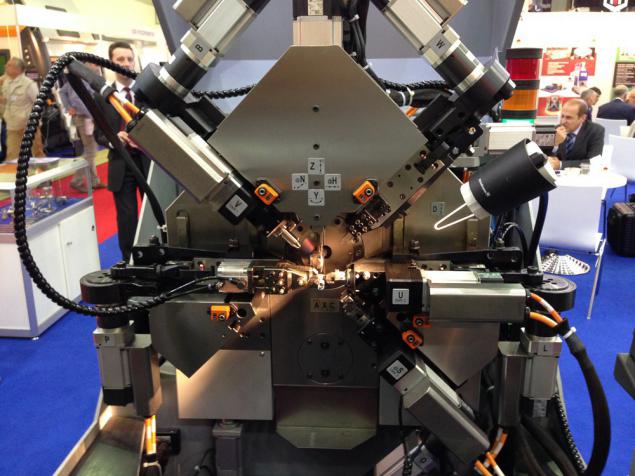

And so for example, looks provolokogibochny machine with a capital SIFCO:

Maybe from doing anything - from springs to Staples:

Or flowers:

Here is the fact that it is located at the other side - the drive rotation and wire feed:

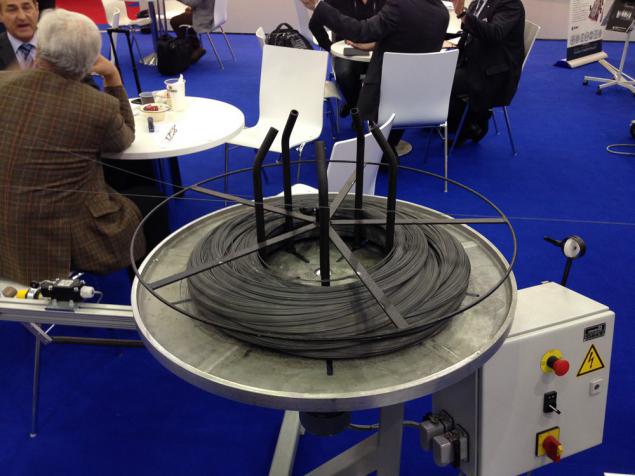

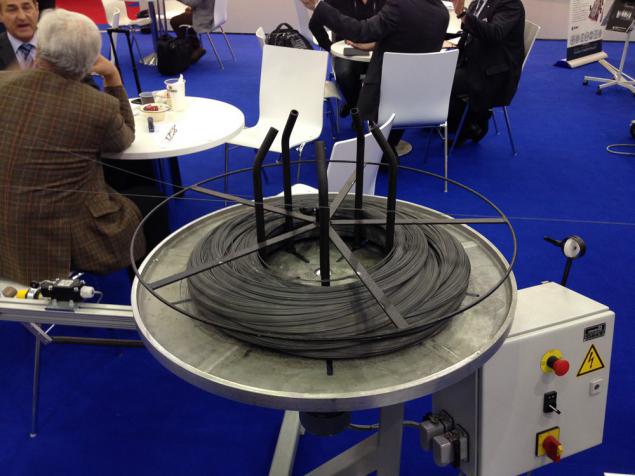

And the wire is unwound from a coil here:

Once again, the process of working with a quality better:

If you like the sound and without acceleration, you can see here (by the way, subscribe).

Here are a number of similar machines, but more specialized - sharpened by the spring.

The wire is unwound (such as coils):

And enters the working area:

The outcome of the springs are a variety of configurations:

But the coordinate measuring machine.

She engaged in that pokes here such probes:

In different parts. Details tsimes is that it can measure deflection sensor workpiece surface of a fault, up to several microns.

And she also has a control program adapted to Windows 8!

The machine that bends hydraulics rails. Well, not exactly the rails, but for a given bend profile piece of iron with a thickness rails it will not be difficult.

She even uncheck the impression - big, tall man with almost smells of oil and with a flower at the side.

And it's the same company, but for bending sheets:

But the wire EDM machine:

This is a "welding vice versa." Brass wire, filed here:

As to the details in a liquid dielectric (usually use distilled water):

Generator creates between the wire and the workpiece high-voltage pulse, which resulted from parts breaking off a small piece. This method can accurately handle any metal without heat and incisors. Only quite slowly.

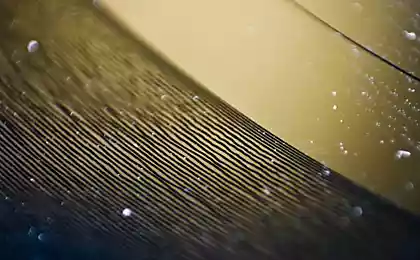

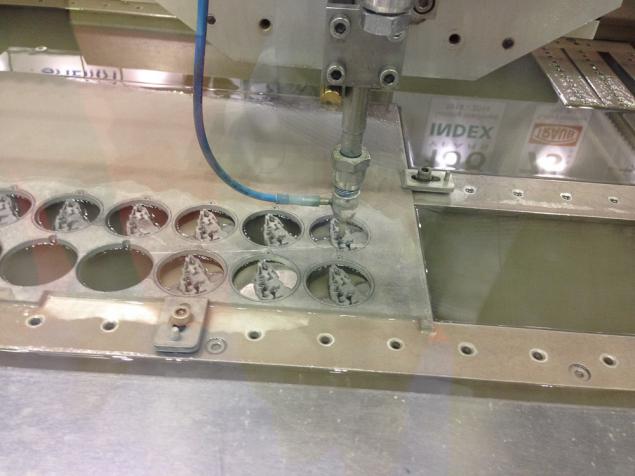

However, the metals can be processed in many ways, such as гидроабразивной sharp :

This machine cuts metal, serving under high pressure (4000 atmospheres) and a speed of the water jet with abrasive - small гранатовым sand:

Cuts in the preparation of any complex contour:

Accuracy - 2.5 microns, cutting speed - 40 cm per minute, with increasing material thickness the speed decreases.

Weighs 8 tons, eats from a network 22 kilowatts.

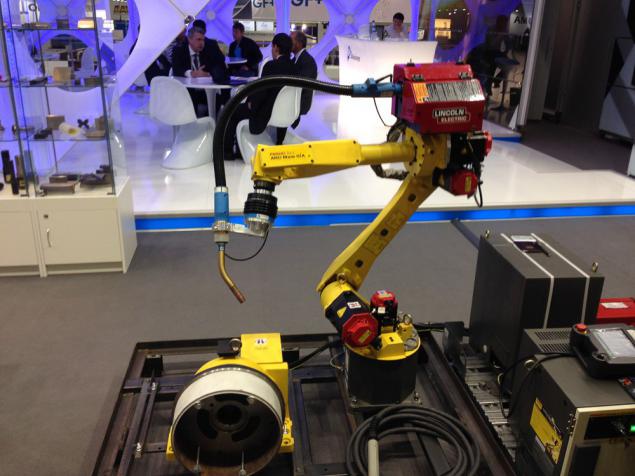

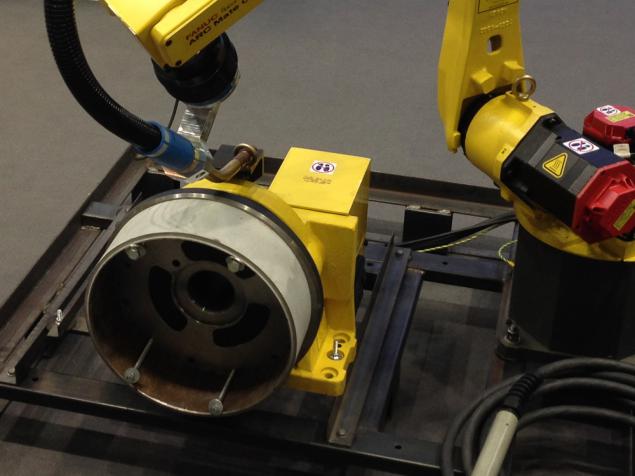

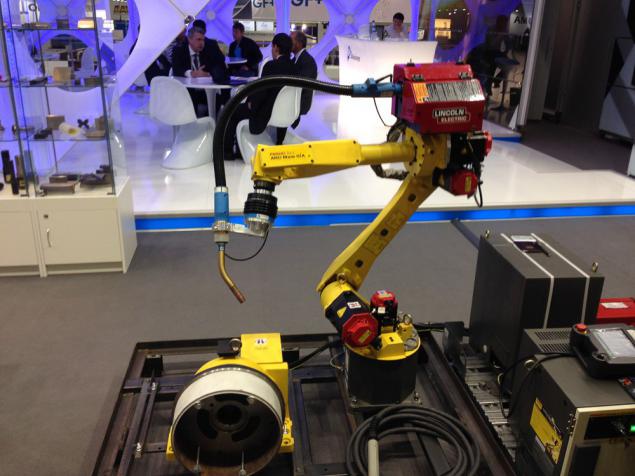

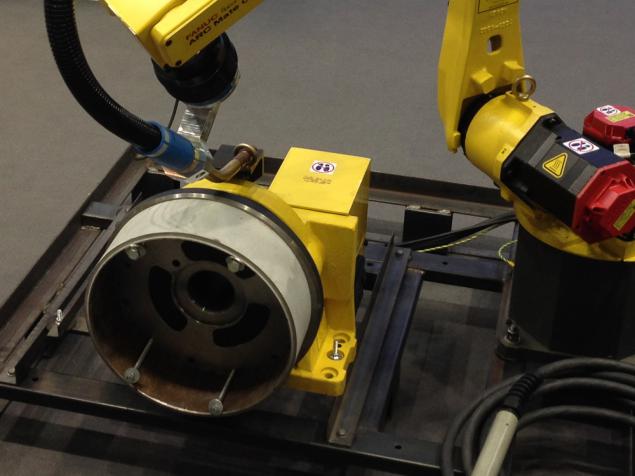

And the metals can be welded. If you manually do it laziness, it is possible to take just such a hand united with welding and rotating platform (bottom):

She can climb through this hole here and cook something inside.

Videos I've lost so dragged at Dru4 with similar hands:

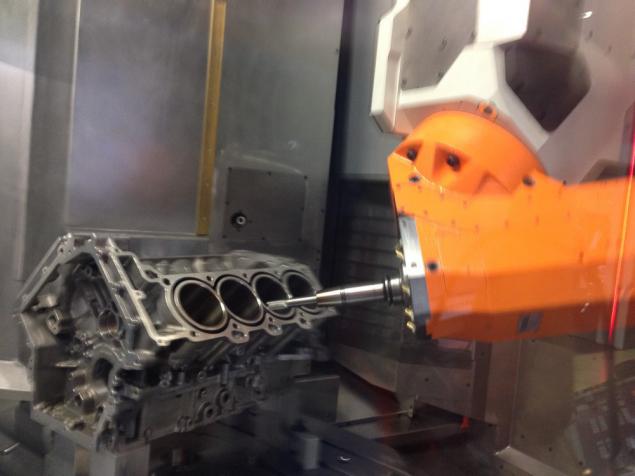

There were a variety of axis CNC machines. Such steep as in this legendary video I have not seen, but there were many other, less complex. But similar:

This orange fool, despite the large amount and for sure, the weight was moving so fast that I did and could not take pictures normally.

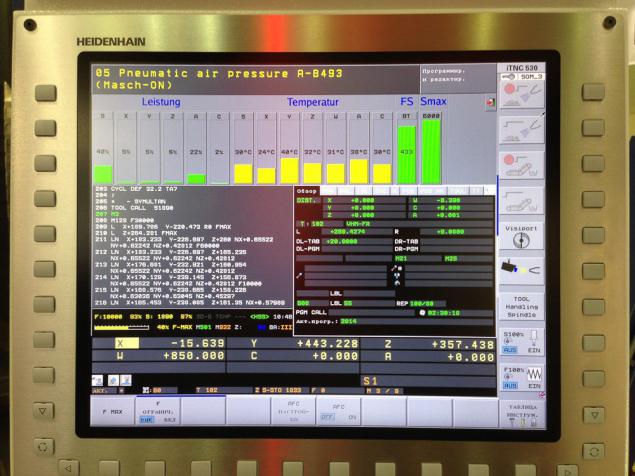

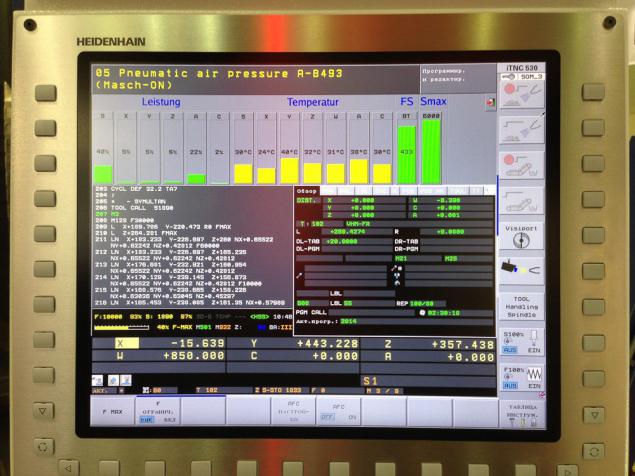

But the panel, I was able to photograph:

Screen closer:

True, it was in demo mode (= fast moving, no cutting). But this one really carved lathe detalku:

Here the control panel already poglamurnee:

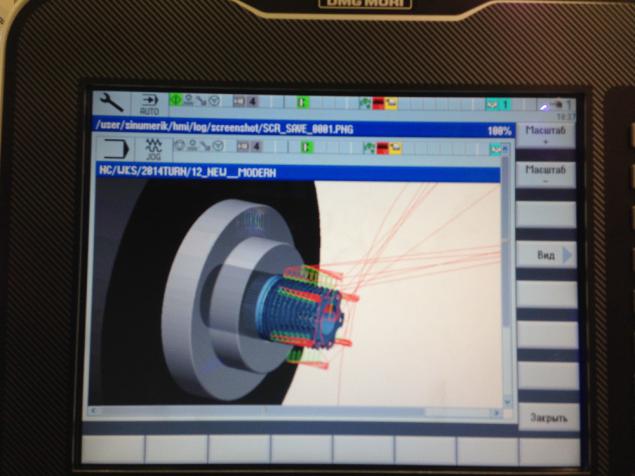

And on the small screen, you can see the trajectory of the head:

Worth this machine about 5 million rubles.

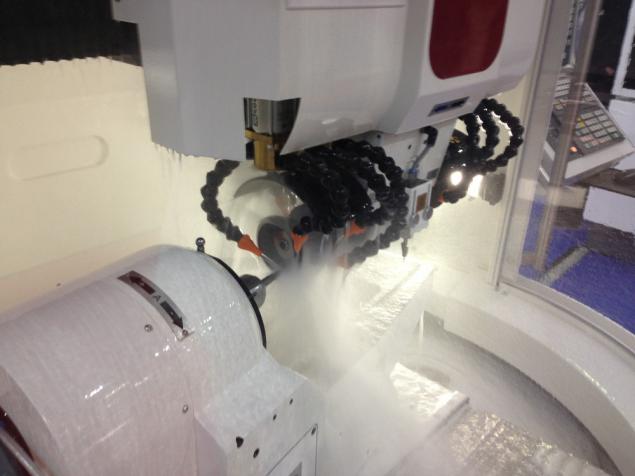

And this machine looks like a shower:

Because it is partly her:

To facilitate cutting, and reduce the temperature of the cutter and the items during processing them generous pouring jet lubrication. Generously - because it is re-used, the pump at the bottom of the cleaned grease collects and delivers it back to the injector.

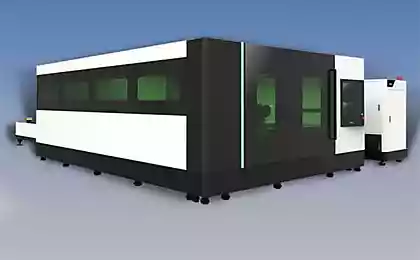

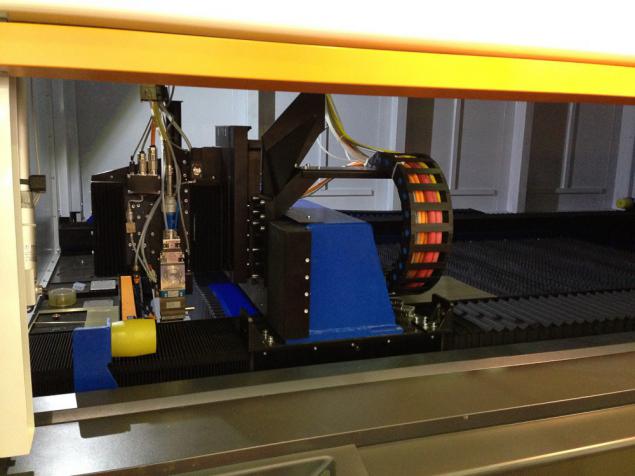

Another metal can be cut by laser!

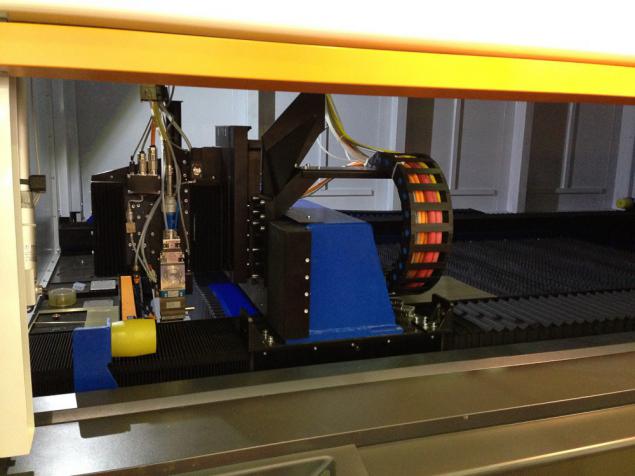

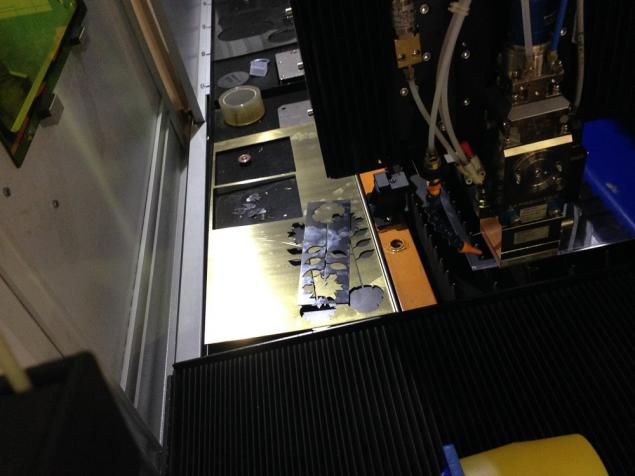

Unfortunately, the process of cutting photograph could not really, it was dark and some flash. Here's innards:

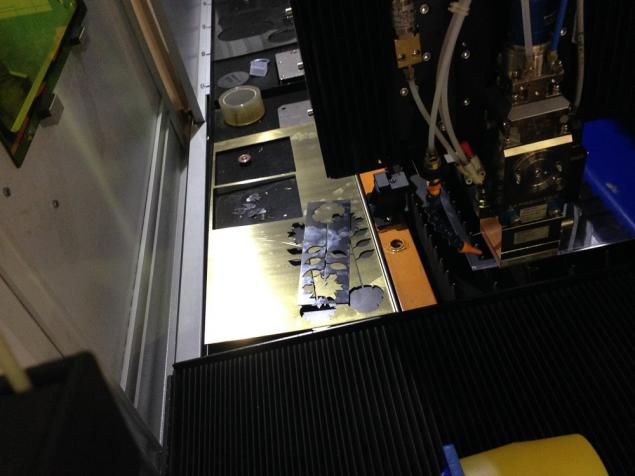

Side piece to which all of the tube - this is the laser head. And here is the results of cutting:

And here:

In my opinion, it would figure, like this:

Not only out of plywood and brass.

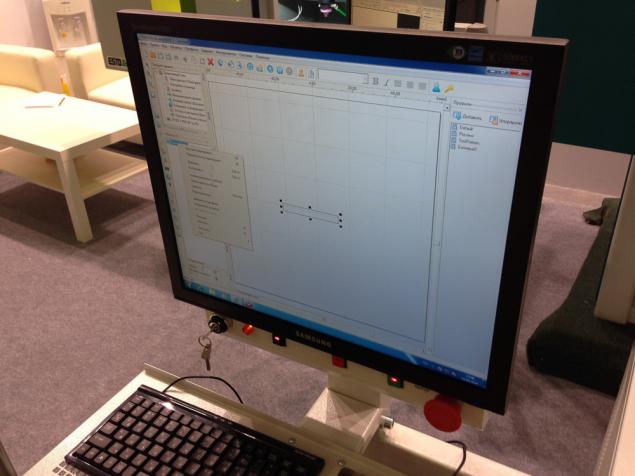

Control Panel - a regular computer. Only the keyboard closed grip of metal (probably cut it the same),

And USB lid closed:

And the metals can be marked.

But only metals. Of metallic materials, I found only a carbine and a recorder (about aluminum laptop forgot. Perhaps fortunately)

Put there titanium karabinchik:

Suggests, focus, exhibiting the work area:

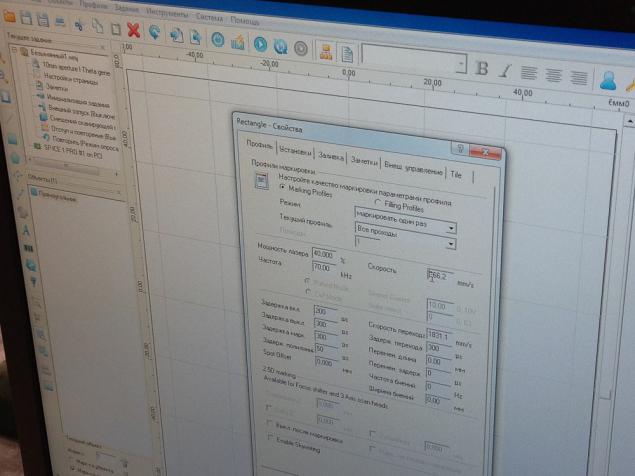

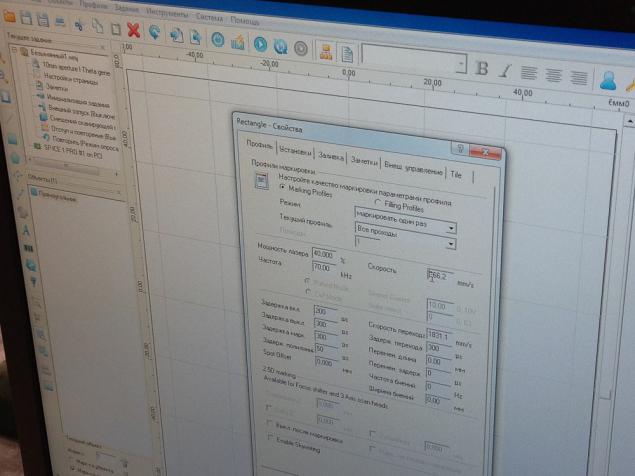

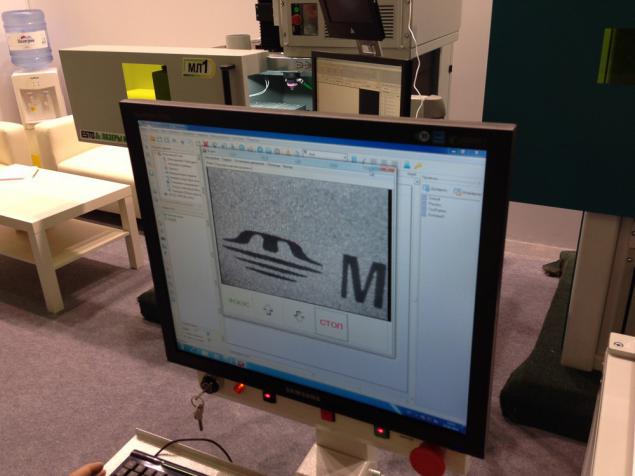

Configure the parameters of the laser:

And once!

"Cut" inscription. Actually - deepened to the level of the inscription. Two - and cuts over another inscription:

Put the recorder:

Focus:

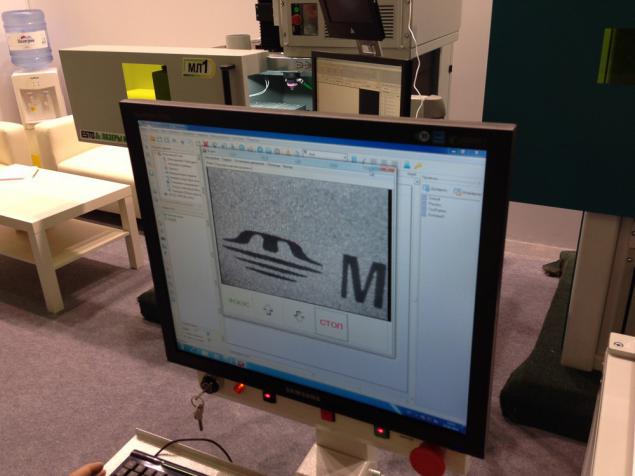

Run:

Obtain just such a label (though slightly oblique, not exactly put)

White lettering because he himself without aluminum oxide film is very light. What's cooler, industrial robots or humanoid? Industrial! Humanoid! I UFO ... Only registered users can vote in polls. Sign , please. Votes 454. 50 people abstained.

Source: habrahabr.ru/company/madrobots/blog/227081/

I apologize in advance for up to 800 kilobytes gifyatiny kata. Then it will be worse.

Unfortunately, due to lack of time, I have been in only one of the pavilion 7, but there was a lot of fun.

And so for example, looks provolokogibochny machine with a capital SIFCO:

Maybe from doing anything - from springs to Staples:

Or flowers:

Here is the fact that it is located at the other side - the drive rotation and wire feed:

And the wire is unwound from a coil here:

Once again, the process of working with a quality better:

If you like the sound and without acceleration, you can see here (by the way, subscribe).

Here are a number of similar machines, but more specialized - sharpened by the spring.

The wire is unwound (such as coils):

And enters the working area:

The outcome of the springs are a variety of configurations:

But the coordinate measuring machine.

She engaged in that pokes here such probes:

In different parts. Details tsimes is that it can measure deflection sensor workpiece surface of a fault, up to several microns.

And she also has a control program adapted to Windows 8!

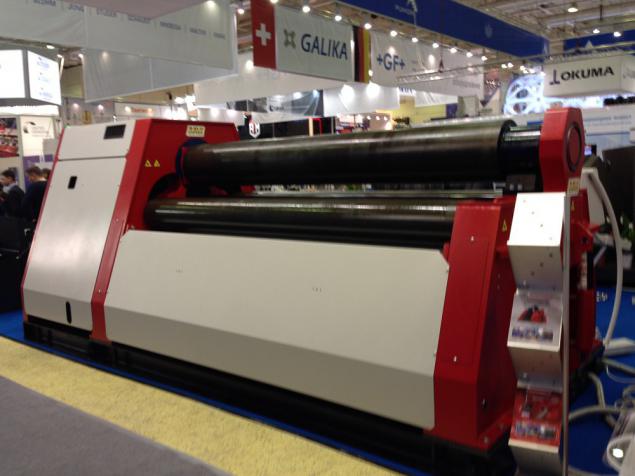

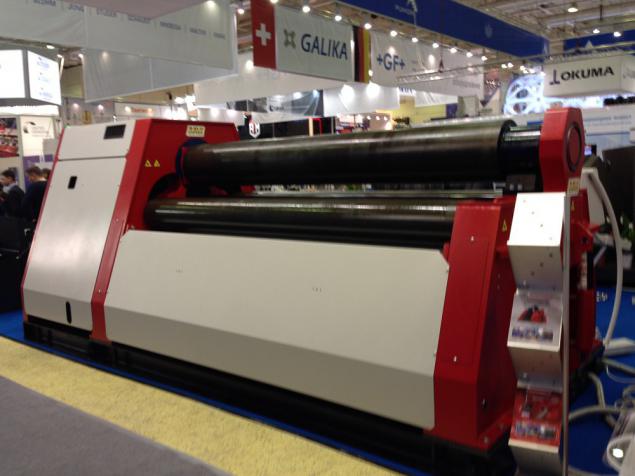

The machine that bends hydraulics rails. Well, not exactly the rails, but for a given bend profile piece of iron with a thickness rails it will not be difficult.

She even uncheck the impression - big, tall man with almost smells of oil and with a flower at the side.

And it's the same company, but for bending sheets:

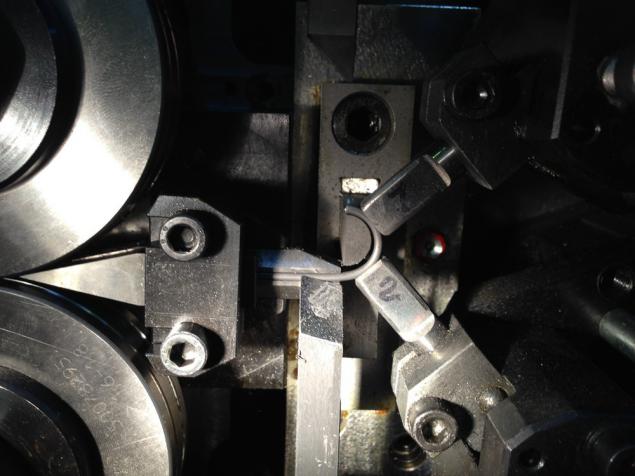

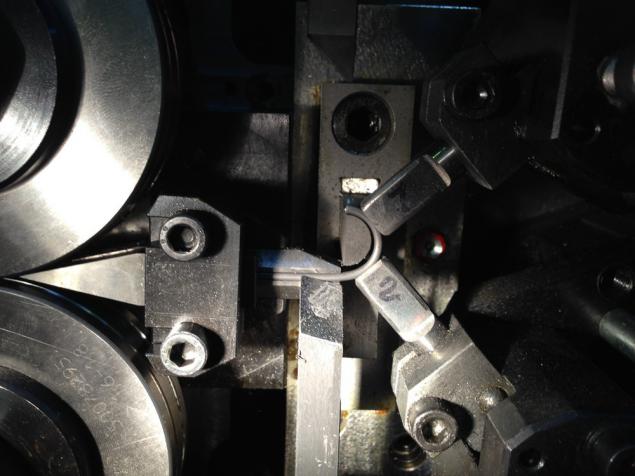

But the wire EDM machine:

This is a "welding vice versa." Brass wire, filed here:

As to the details in a liquid dielectric (usually use distilled water):

Generator creates between the wire and the workpiece high-voltage pulse, which resulted from parts breaking off a small piece. This method can accurately handle any metal without heat and incisors. Only quite slowly.

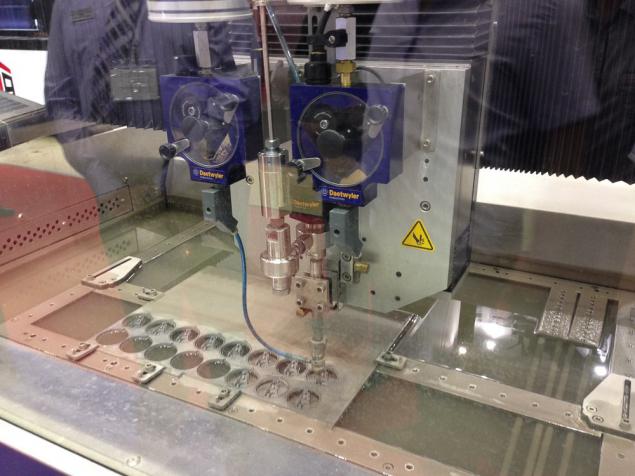

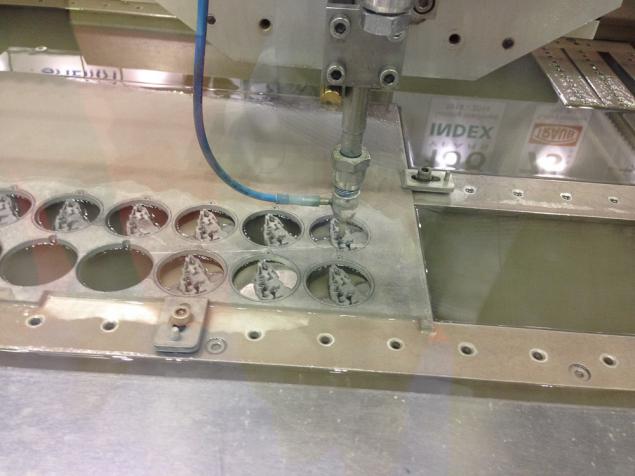

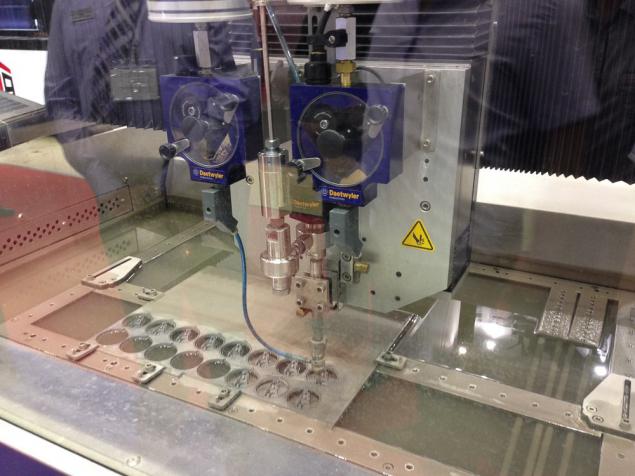

However, the metals can be processed in many ways, such as гидроабразивной sharp :

This machine cuts metal, serving under high pressure (4000 atmospheres) and a speed of the water jet with abrasive - small гранатовым sand:

Cuts in the preparation of any complex contour:

Accuracy - 2.5 microns, cutting speed - 40 cm per minute, with increasing material thickness the speed decreases.

Weighs 8 tons, eats from a network 22 kilowatts.

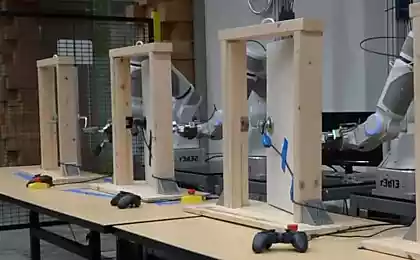

And the metals can be welded. If you manually do it laziness, it is possible to take just such a hand united with welding and rotating platform (bottom):

She can climb through this hole here and cook something inside.

Videos I've lost so dragged at Dru4 with similar hands:

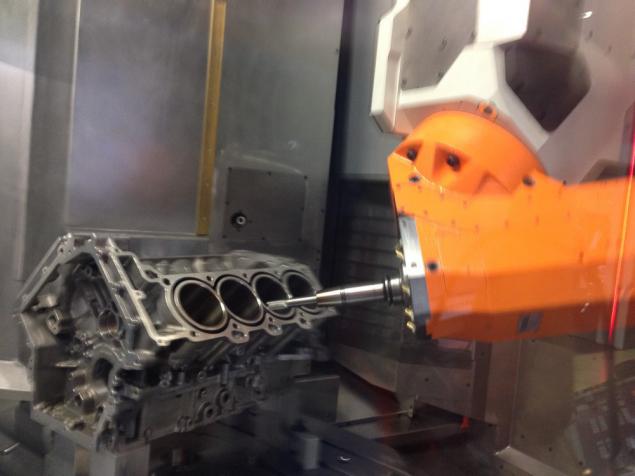

There were a variety of axis CNC machines. Such steep as in this legendary video I have not seen, but there were many other, less complex. But similar:

This orange fool, despite the large amount and for sure, the weight was moving so fast that I did and could not take pictures normally.

But the panel, I was able to photograph:

Screen closer:

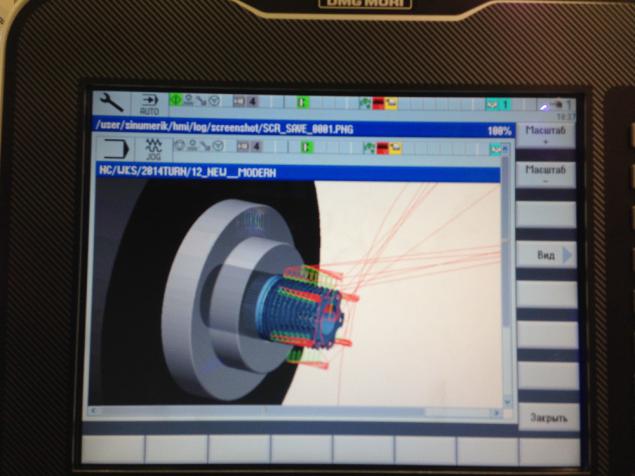

True, it was in demo mode (= fast moving, no cutting). But this one really carved lathe detalku:

Here the control panel already poglamurnee:

And on the small screen, you can see the trajectory of the head:

Worth this machine about 5 million rubles.

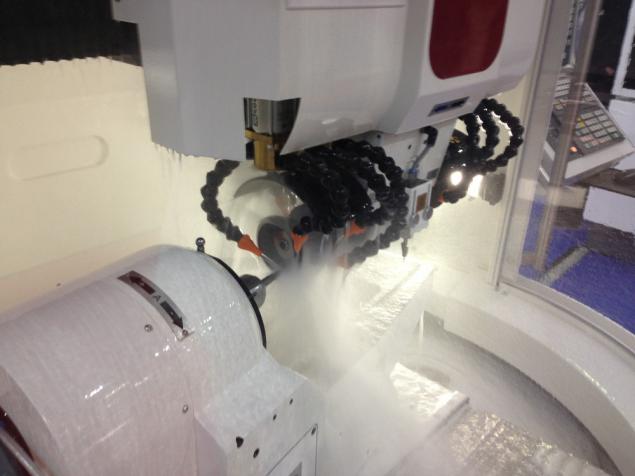

And this machine looks like a shower:

Because it is partly her:

To facilitate cutting, and reduce the temperature of the cutter and the items during processing them generous pouring jet lubrication. Generously - because it is re-used, the pump at the bottom of the cleaned grease collects and delivers it back to the injector.

Another metal can be cut by laser!

Unfortunately, the process of cutting photograph could not really, it was dark and some flash. Here's innards:

Side piece to which all of the tube - this is the laser head. And here is the results of cutting:

And here:

In my opinion, it would figure, like this:

Not only out of plywood and brass.

Control Panel - a regular computer. Only the keyboard closed grip of metal (probably cut it the same),

And USB lid closed:

And the metals can be marked.

But only metals. Of metallic materials, I found only a carbine and a recorder (about aluminum laptop forgot. Perhaps fortunately)

Put there titanium karabinchik:

Suggests, focus, exhibiting the work area:

Configure the parameters of the laser:

And once!

"Cut" inscription. Actually - deepened to the level of the inscription. Two - and cuts over another inscription:

Put the recorder:

Focus:

Run:

Obtain just such a label (though slightly oblique, not exactly put)

White lettering because he himself without aluminum oxide film is very light. What's cooler, industrial robots or humanoid? Industrial! Humanoid! I UFO ... Only registered users can vote in polls. Sign , please. Votes 454. 50 people abstained.

Source: habrahabr.ru/company/madrobots/blog/227081/

"It still works!": How two friends accidentally made a 3d-revolution, devising Dudler

The national idea (rules of construction)