290

CNC machines - high-precision machining, virtually waste-free production

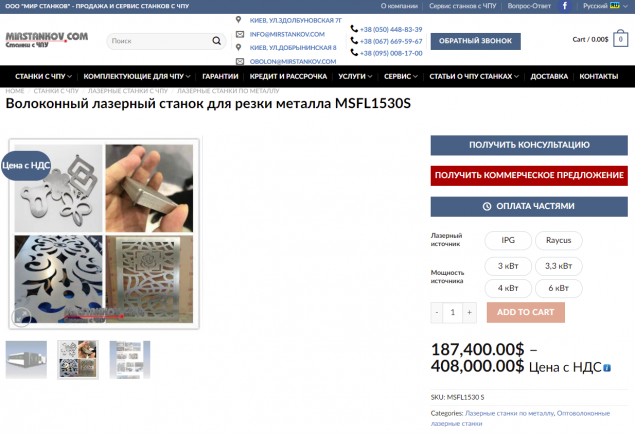

Industrial equipment today is being upgraded at high speeds. Market relations force manufacturers to acquire and manufacture in high-tech facilities. CNC machines for various purposes, presented on the website https://mirstankov.com/shop/oborudovanie/, are coordinated by a computer under the control of a qualified operator. The system allows you to completely eliminate the human factor, reduce the likelihood of marriage to almost zero.

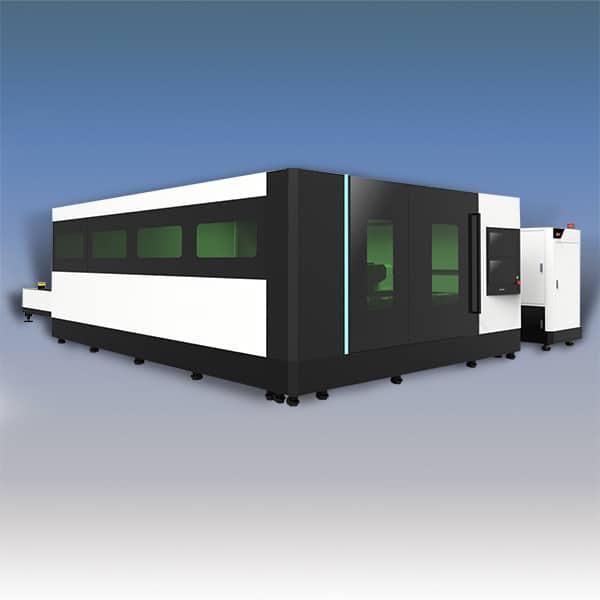

Varieties of CNC equipment

Machine tool manufacturers produce the following types of machines:

- laser, fiber optic and carbon dioxide models;

- engraving and milling, performing processing in several axes at the same time;

- equipment that solves specific tasks: cutting and electroerosive plotters, plasma devices.

Four to five axis mills provide the ability to process workpieces in 3D format. Carbon dioxide lasers work with soft materials (plywood, wood, leather, and others).

Fiber optic models are capable of producing products and solid metals. They are used for the manufacture of components, stainless steel products and other grades of steel.

Features of high-tech machine tools

Modern CNC equipment has expanded the range of materials that can be processed with high precision. High-tech machine tools can manufacture products, produce components from workpieces with different physical properties and geometric configurations. The parameters do not affect production. The machines always ensure the high quality of the finished product. The presence of CNC provides the following capabilities:

- increasing the productivity of equipment;

- increasing technological capabilities;

- serial production of products reduces its cost;

- parts are made with high precision, identical to repeatable ones.

The machines are controlled by a computer or a special controller. All processing parameters, the trajectory of the cutting tool are under constant control at all stages of production. Under such conditions, the machines are able to work in an autonomous mode, according to a given program, without the participation of an operator.

Industrial equipment today is being upgraded at high speeds. Market relations force manufacturers to acquire and manufacture in high-tech facilities. For various purposes, CNC machines, presented on the website mirstankov.com/shop/oborudovanie, are coordinated by a computer under the control of a qualified operator. The system allows you to completely eliminate the human factor, reduce the likelihood of marriage to almost zero.

How to Eradicate the Manners of Mother-in-law Who Retired

Mother-in-law brought a bucket of red currant, baked exquisite pies all week