1833

Hexapod B.U.N.T

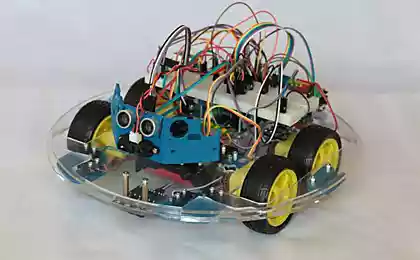

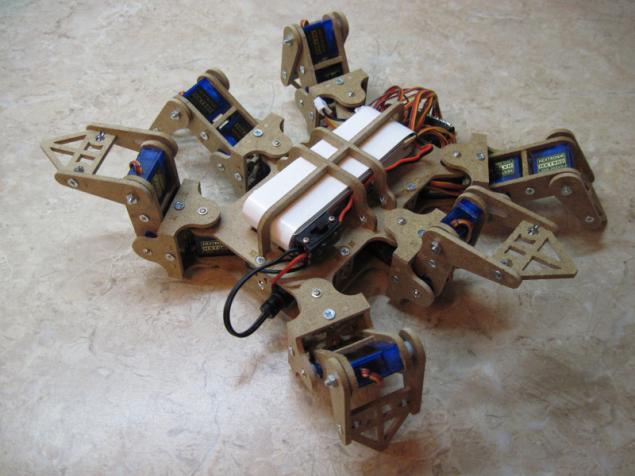

Watching the video on youtube about hexapods (especially impressed PhantomX), decided to try his hand at robotics. Looking ahead - all happened and here's the result:

All interested in asking a cat, there briefly describes the history of creation and the difficulties encountered, as well as video of the hexapod. Nor any graphs, diagrams and code, only the lyrics.

With arduino was already familiar, but with servprivodami worked. Long read, understood assortment serv, eventually decided to take the tiny HXT900 , although in this post and says that on the feeble Servakh hexapod barely stand on his feet, but I decided to take a chance. Just ordered the Arduino Mega, battery Turnigy 2200mAh 3S 20C Lipo Pack stabilizer and TURNIGY 8-15A UBEC . After receiving all necessary, removed all sizes caliper and started drawing the design first, and then the drawing itself and hexapod. For archetype took PhantomX, liked how his serfs located. For lack of aluminum and inability to cut Plexiglas on the machine, it was decided to make all parts of trёhmillimetrovoy MDF, what pity, but more on that later. Actually because of the housing material and it occurred to call hexapod B.U.N.T. - Pinocchio is not the same. To reduce the size, "ears" have been ruthlessly cut down serv, as seen in the pictures below.

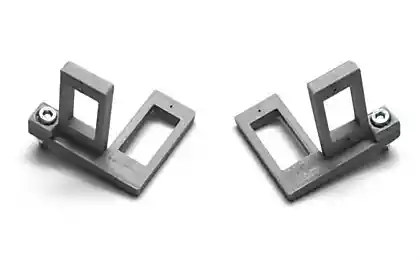

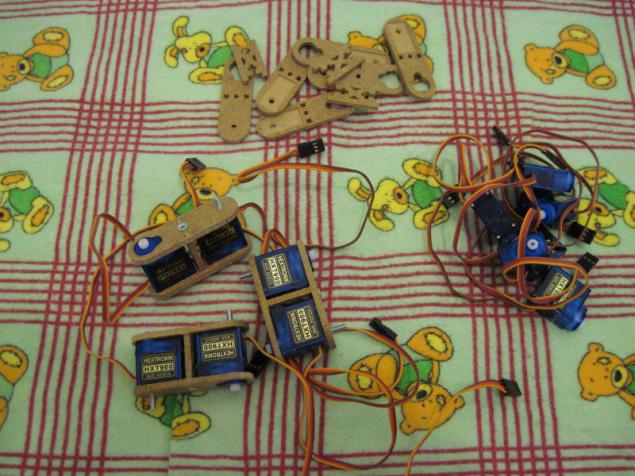

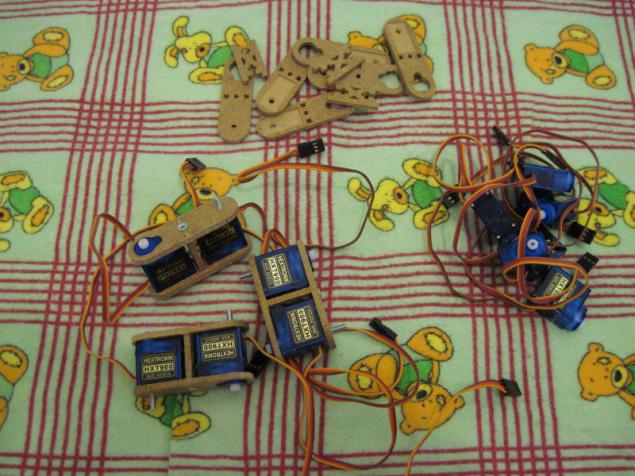

Pictures of the build process connects two servos in a single unit.

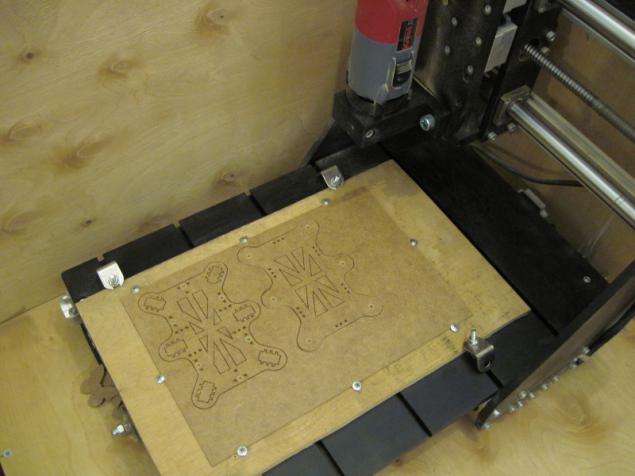

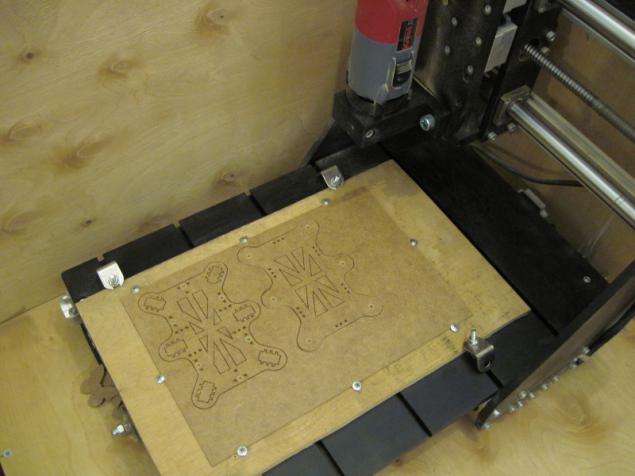

We cut body parts

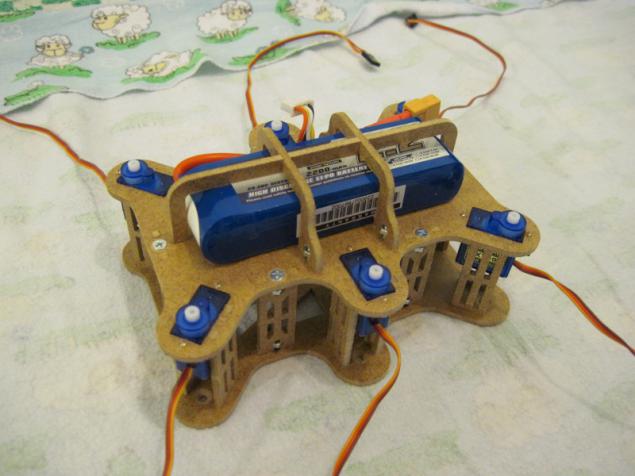

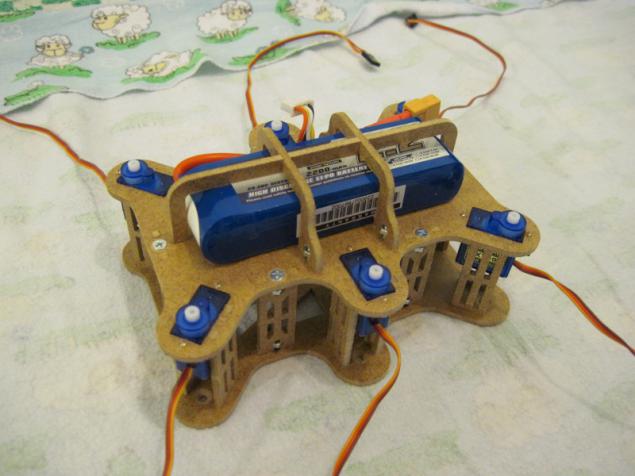

Housing Assembly, only this bird seemed to me stout - had to redo, and this in the trash.

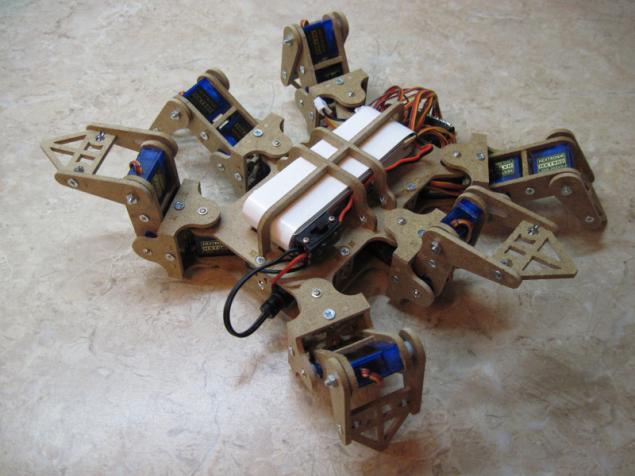

Finishing Touches - carcasses collected, left foot tie.

Photos little as a process carried away and completely forgot to photograph. If you have noticed - the last two photographs battery looks different - at last he was without a label. Just when you place orders, somehow did not think that you need to buy more specific XT60 connector for connection to the battery load. In the end, had to "bite" connector and solder. According to my carelessness krivorukost shorted and the voltage across the drain. Pomeroy multimeter voltage at the terminals of the charger connector, realized that lost contact between the "Bank". Disassemble the battery pack, found a gap - blown aluminum "petal" (minus) in one bank, with nearly at the root. Tried podpoyatsya - but having soldering acid aluminum does not take. Upset was about to order a new battery, but after a short gugleniya was bought flux F64, which, as it turned out, not solder aluminum harder than copper. Hardly able to solder to the remains of "petals" and the battery has been revived. Next, at step assembly revealed that the idea to use the Mega Sensor Shield failed - because it bird gets too thick and ugly. I had to redo the drawings and reduce the thickness of a carcass to the height of the actuator, which eventually led to the fact that the wires from the servos to the carcass itself is not entirely together - part of which served food was submitted to the outside. But even so beautiful (and stronger) than with thick carcass. Collect the fine details of MDF - what more fun. Without a file connections just not into each other, though, and left a gap - prevent sharp edges. The whole structure looks hlipkovatoy there a small gap, but overall not bad happened and are quite reliable, most importantly do not soak, and that will lead. Hexapod is assembled, the first test and proves that he is well on his feet and completely withstand the weight. It weighs 640 grams way. In the first experiments on its krivorukost of annoying bugs in the code from one of the serv frustrated GEAR - was specified too large angle and put her foot in the carcass. I had to disassemble and change the servo blessing took stock. After some deliberation was written by a small sketch for a simple straight away. Sketch me ashamed to spread, but the video will show the first steps hexapod with pleasure.

Video

Total:

Collect hexapod not so difficult Mikroservy are not that weak Do not skimp on / do not forget the battery connectors - solder energized bad idea Servais always take with a margin If there is an opportunity - make aluminum - if not, then the plastic (Plexiglas), in the extreme case of MDF, although not, MDF is better not to do And yes, I almost forgot, all accessories, MDF and other cost me about 5 thousand. With the joystick, Shield (which proved unnecessary) and other small things (which is also almost not used) is roughly 6000. But the quality of the finished product is far from PhantomX, but I was ready for it.

Source: habrahabr.ru/post/219051/

All interested in asking a cat, there briefly describes the history of creation and the difficulties encountered, as well as video of the hexapod. Nor any graphs, diagrams and code, only the lyrics.

With arduino was already familiar, but with servprivodami worked. Long read, understood assortment serv, eventually decided to take the tiny HXT900 , although in this post and says that on the feeble Servakh hexapod barely stand on his feet, but I decided to take a chance. Just ordered the Arduino Mega, battery Turnigy 2200mAh 3S 20C Lipo Pack stabilizer and TURNIGY 8-15A UBEC . After receiving all necessary, removed all sizes caliper and started drawing the design first, and then the drawing itself and hexapod. For archetype took PhantomX, liked how his serfs located. For lack of aluminum and inability to cut Plexiglas on the machine, it was decided to make all parts of trёhmillimetrovoy MDF, what pity, but more on that later. Actually because of the housing material and it occurred to call hexapod B.U.N.T. - Pinocchio is not the same. To reduce the size, "ears" have been ruthlessly cut down serv, as seen in the pictures below.

Pictures of the build process connects two servos in a single unit.

We cut body parts

Housing Assembly, only this bird seemed to me stout - had to redo, and this in the trash.

Finishing Touches - carcasses collected, left foot tie.

Photos little as a process carried away and completely forgot to photograph. If you have noticed - the last two photographs battery looks different - at last he was without a label. Just when you place orders, somehow did not think that you need to buy more specific XT60 connector for connection to the battery load. In the end, had to "bite" connector and solder. According to my carelessness krivorukost shorted and the voltage across the drain. Pomeroy multimeter voltage at the terminals of the charger connector, realized that lost contact between the "Bank". Disassemble the battery pack, found a gap - blown aluminum "petal" (minus) in one bank, with nearly at the root. Tried podpoyatsya - but having soldering acid aluminum does not take. Upset was about to order a new battery, but after a short gugleniya was bought flux F64, which, as it turned out, not solder aluminum harder than copper. Hardly able to solder to the remains of "petals" and the battery has been revived. Next, at step assembly revealed that the idea to use the Mega Sensor Shield failed - because it bird gets too thick and ugly. I had to redo the drawings and reduce the thickness of a carcass to the height of the actuator, which eventually led to the fact that the wires from the servos to the carcass itself is not entirely together - part of which served food was submitted to the outside. But even so beautiful (and stronger) than with thick carcass. Collect the fine details of MDF - what more fun. Without a file connections just not into each other, though, and left a gap - prevent sharp edges. The whole structure looks hlipkovatoy there a small gap, but overall not bad happened and are quite reliable, most importantly do not soak, and that will lead. Hexapod is assembled, the first test and proves that he is well on his feet and completely withstand the weight. It weighs 640 grams way. In the first experiments on its krivorukost of annoying bugs in the code from one of the serv frustrated GEAR - was specified too large angle and put her foot in the carcass. I had to disassemble and change the servo blessing took stock. After some deliberation was written by a small sketch for a simple straight away. Sketch me ashamed to spread, but the video will show the first steps hexapod with pleasure.

Video

Total:

Collect hexapod not so difficult Mikroservy are not that weak Do not skimp on / do not forget the battery connectors - solder energized bad idea Servais always take with a margin If there is an opportunity - make aluminum - if not, then the plastic (Plexiglas), in the extreme case of MDF, although not, MDF is better not to do And yes, I almost forgot, all accessories, MDF and other cost me about 5 thousand. With the joystick, Shield (which proved unnecessary) and other small things (which is also almost not used) is roughly 6000. But the quality of the finished product is far from PhantomX, but I was ready for it.

Source: habrahabr.ru/post/219051/

Google will provide all residents of the United States the opportunity to one day buy glasses Google Glass

Nude Rihanna on photography