1517

Making sausage and jerked sausage

Sausage sausage is the most time consuming and often not predictable generating products in any enterprise. The complexity of manufacturing this type of sausage is caused by many factors (weather conditions, ambient temperature, environmental conditions, etc.).

To successfully produce high quality and guaranteed product, you must have full confidence in the raw materials, such as:

* Only the meat of adult animals 3-5 years

* Only spinal fat from the special breed of pigs with high melting points

* Spice neutralized, sterilized

* Salt Evaporated premium special cleaning

* Protein coat well "breathing" and has no contamination by microorganisms

and that not all of the parameters that should be considered before proceeding with the production of sausage sausages. You also need a special and sophisticated equipment, such as:

Cutter (machine for fine grinding mince from Eng. Cut - cut, cut) should have a special shape of the knife for a thorough supply of meat under the knife itself with the aim of cutting and is not acceptable that these knives were sharpened badly. Sharpening the cutter knives is made on a special automated line, the operator can only set the knife to get back after sharpening. With this grinding machine manages to achieve good results cutting

Quite important is the moment from which made the cup of the cutter so that was not the slightest rust and microscopic roughness, in other words a complete hygiene, so as not to inseminate minced microorganisms. From hygienic reasons cutter installed at the company, made of stainless steel only.

Climate chamber responsible for dehydration and smoked products. At the beginning of climatic processing sausages in the chamber, the conditions identical to the processed product, then gradually set those parameters, which should reach the sausage in the technological progress. So hour after hour, step by step, day and night guard is the quality of the computer-controlled desired mode. The first step is the selection of raw materials. Selection is carried out as a visual determination of quality indicators of meat (dirt, color), and rapid methods of laboratory instruments (pH meter, thermometer, salimeter, as well as a device for measuring water activity AB). Due to the above method of determining the raw material manages to best prepare for this type of product.

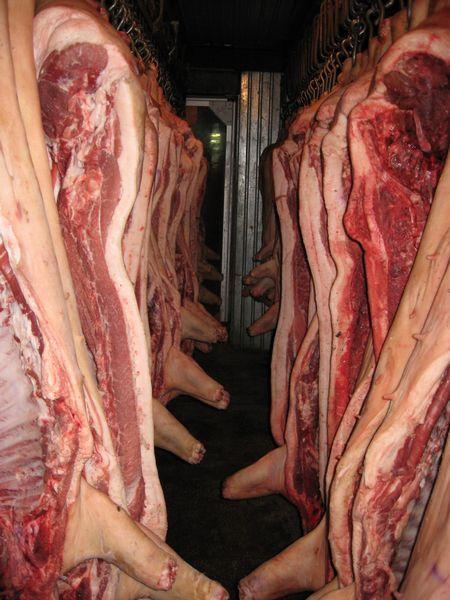

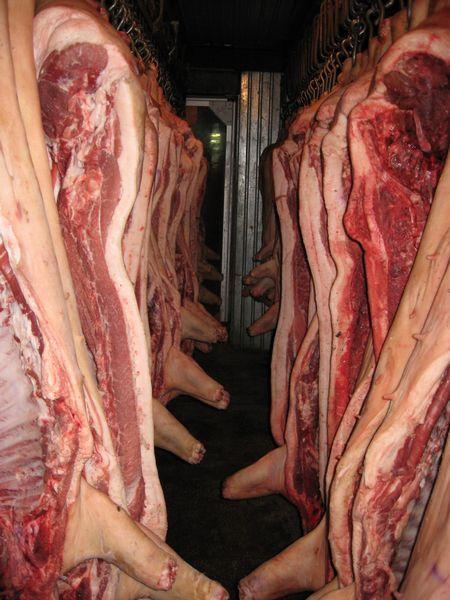

The next step is boning, trimming, sorting of raw meat in the destination a different kind of sausages, as well as preparation of bacon.

According to a special procedure and principles developed in our company all raw meat enters the deep freeze -20 ° C in blocks.

After freezing the blocks are crushed by special machines intended for grinding the frozen meat with a temperature of -20 ° C. Volchёk - a giant meat grinder, a leading German manufacturer with 1843 «Seydelmann»

Crusher of frozen blocks «MAGURIT»

The next stage of processing proceeds to the cutter meat, where it is making available to the final fraction meat and bacon pieces, and mixing with sugar, spices and salt. Incremental compilation keeping meat, see below: In this case, produced minced sausage sausage premium "grain" grinding beef premium:

Bookmark and grinding bacon spinal

To equalize the temperature and stability of meat, some of the raw material is put into fresh

Now, spices and salt.

Thoroughly mixed and ready minced.

Unloading minced automatically.

Ready minced sausage is directed to forming the shell.

Fill shells made on automated syringes fillers HANDTMANN VF 628 in tandem with clippers POLY-CLIP, ALPINA. This equipment is manufactured in Germany and is the best in the world, forming part of the sausage.

Ready loaves are mounted on movable frames sausages using hinged sticks.

Stuffed Sausage frames are sent to a particular time in the shop temperature equalization.

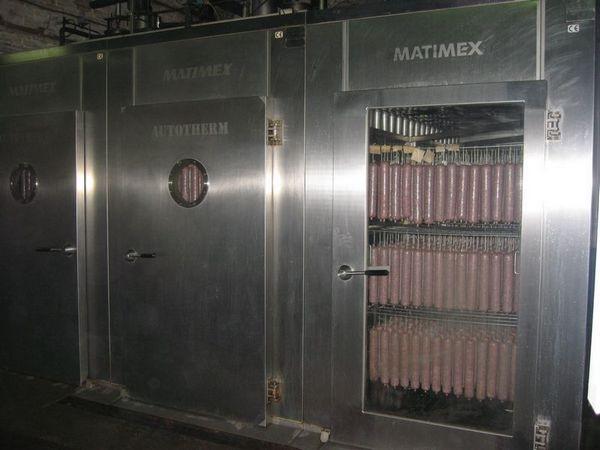

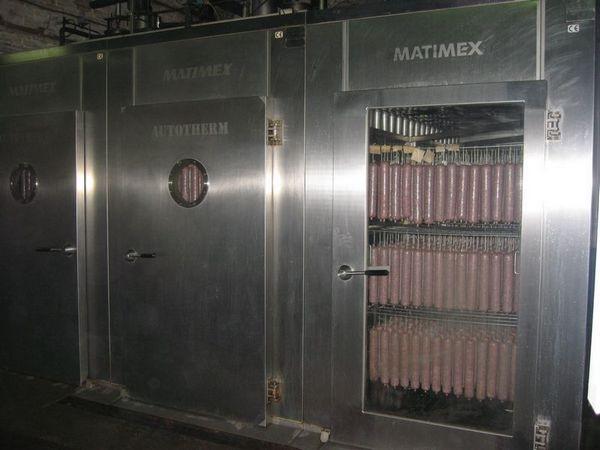

Now, in environmental chambers AUTOTHERM (Germany), where the sausage will remain for five days. During this time she was freed from excess moisture will be exposed to smoking in the safe smoke.

All processes in the climate chamber are monitored by a computer, which was designed specifically for our production in Germany. This computer program is laid accurate hourly with all processing modes (humidity, air flow, the amount of smoke, cooling, heating, time, etc..).

Five days later, an expert in the production of sausages sausage, determines its readiness to treatment at this stage.

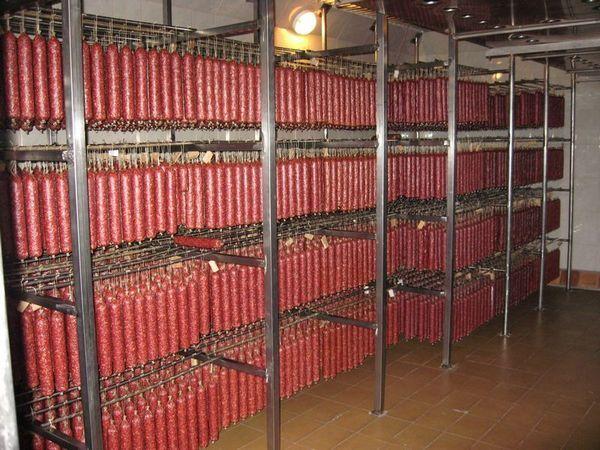

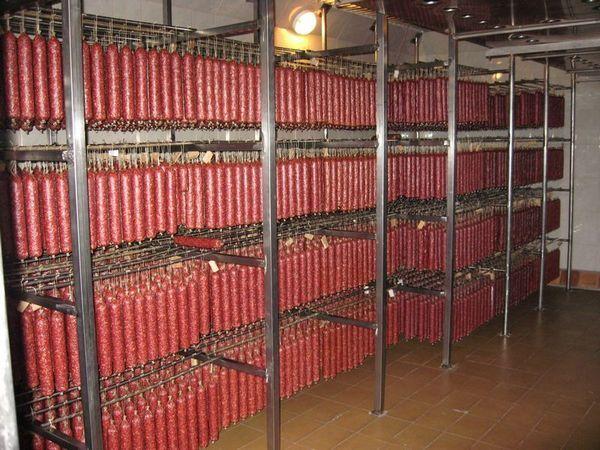

Sausage sent into the drying climate chamber, where it will remain during the next twenty-five days.

After a full production cycle, each loaf goes to the marking machine, which receives a label with the name.

Part of the production is sent to the slicing.

This happens manufacturing sausage sausages for thirty, thirty-five days. Sausages for the period of time to lose 45 - 50% of the original mass, which partly driven by the high cost of these products.

via source

To successfully produce high quality and guaranteed product, you must have full confidence in the raw materials, such as:

* Only the meat of adult animals 3-5 years

* Only spinal fat from the special breed of pigs with high melting points

* Spice neutralized, sterilized

* Salt Evaporated premium special cleaning

* Protein coat well "breathing" and has no contamination by microorganisms

and that not all of the parameters that should be considered before proceeding with the production of sausage sausages. You also need a special and sophisticated equipment, such as:

Cutter (machine for fine grinding mince from Eng. Cut - cut, cut) should have a special shape of the knife for a thorough supply of meat under the knife itself with the aim of cutting and is not acceptable that these knives were sharpened badly. Sharpening the cutter knives is made on a special automated line, the operator can only set the knife to get back after sharpening. With this grinding machine manages to achieve good results cutting

Quite important is the moment from which made the cup of the cutter so that was not the slightest rust and microscopic roughness, in other words a complete hygiene, so as not to inseminate minced microorganisms. From hygienic reasons cutter installed at the company, made of stainless steel only.

Climate chamber responsible for dehydration and smoked products. At the beginning of climatic processing sausages in the chamber, the conditions identical to the processed product, then gradually set those parameters, which should reach the sausage in the technological progress. So hour after hour, step by step, day and night guard is the quality of the computer-controlled desired mode. The first step is the selection of raw materials. Selection is carried out as a visual determination of quality indicators of meat (dirt, color), and rapid methods of laboratory instruments (pH meter, thermometer, salimeter, as well as a device for measuring water activity AB). Due to the above method of determining the raw material manages to best prepare for this type of product.

The next step is boning, trimming, sorting of raw meat in the destination a different kind of sausages, as well as preparation of bacon.

According to a special procedure and principles developed in our company all raw meat enters the deep freeze -20 ° C in blocks.

After freezing the blocks are crushed by special machines intended for grinding the frozen meat with a temperature of -20 ° C. Volchёk - a giant meat grinder, a leading German manufacturer with 1843 «Seydelmann»

Crusher of frozen blocks «MAGURIT»

The next stage of processing proceeds to the cutter meat, where it is making available to the final fraction meat and bacon pieces, and mixing with sugar, spices and salt. Incremental compilation keeping meat, see below: In this case, produced minced sausage sausage premium "grain" grinding beef premium:

Bookmark and grinding bacon spinal

To equalize the temperature and stability of meat, some of the raw material is put into fresh

Now, spices and salt.

Thoroughly mixed and ready minced.

Unloading minced automatically.

Ready minced sausage is directed to forming the shell.

Fill shells made on automated syringes fillers HANDTMANN VF 628 in tandem with clippers POLY-CLIP, ALPINA. This equipment is manufactured in Germany and is the best in the world, forming part of the sausage.

Ready loaves are mounted on movable frames sausages using hinged sticks.

Stuffed Sausage frames are sent to a particular time in the shop temperature equalization.

Now, in environmental chambers AUTOTHERM (Germany), where the sausage will remain for five days. During this time she was freed from excess moisture will be exposed to smoking in the safe smoke.

All processes in the climate chamber are monitored by a computer, which was designed specifically for our production in Germany. This computer program is laid accurate hourly with all processing modes (humidity, air flow, the amount of smoke, cooling, heating, time, etc..).

Five days later, an expert in the production of sausages sausage, determines its readiness to treatment at this stage.

Sausage sent into the drying climate chamber, where it will remain during the next twenty-five days.

After a full production cycle, each loaf goes to the marking machine, which receives a label with the name.

Part of the production is sent to the slicing.

This happens manufacturing sausage sausages for thirty, thirty-five days. Sausages for the period of time to lose 45 - 50% of the original mass, which partly driven by the high cost of these products.

via source