998

Details of the production of red caviar

Interesting article, which tells you about all stages of the production of caviar. Read more.

Perhaps, for many a jar of red caviar is associated with the holiday.

And in actual fact, before you get to your desk, around the feast of caviar no no ... quite the contrary - it is hard work.

With the application a few photos I will try to show briefly.

The bulk of all red caviar produced in Kamchatka and Sakhalin (the Pacific Ocean, the Bering Sea and Sea of Okhotsk). When Putin begins, to the places of fishing fleet rushes. In my particular case, the process is shown in the two-way processing vessel BATM (large standalone freezer trawler), who took the fish with fixed nets on the west coast of Kamchatka.

With fixed nets fishermen catch to supply the miners transceiver processing vessel.

Hoppers in clerk. Hence fish fed by gravity to the line cutting.

Line cutting. There shkeryat fish - eggs put in blue paramushki on top, ulcer in one hole, the fish in another. Gutted fish on the tray flows in the plant on the deck below, guts overboard. The factory gutted washed, sized, frost and packed in containers. Finish in the freezer hold.

Sort yastiks caviar species. Mix the eggs of different fish - an unacceptable crime.

Here and wash yastiks seawater.

At this stage, the eggs are separated from yastiks - rattle. The machine is called - Butare. To make it cleaner - use two grohotki.

Division caviar falls on an inclined gauze. Here, too, are the film pieces and all sorts of rubbish.

Otgrohotannuyu caviar is salted in brine (brine). Simultaneously, salting, caviar and laundered here. The ratio of eggs / brine - 1/3. Salt to saturation calf about 4%. By the time - about 10-20 minutes, depending on the "fortress" of brine.

Incidentally, the brine is boiled here on the deck in such "small saucepan».

After prosolki caviar is packed by a small basket which lay in a centrifuge, where 10-15 minutes of "spin" does spawn almost dry and it gets to the table wizard to add a stretch of oil and preservatives. Here the last control of the purity and quality backlit table below.

Packing table with bottom illumination in order to shine through the thickness of the eggs and were well marked "foreign body" (pieces of blood, film, etc.). In the already salted and ottsentrifuzhennuyu caviar on this table wizard adds and mixes vegetable oil and antiseptics. In the past (before 2010) used methenamine and sorbic acid Now some more "useful" stuff. Before packing in bottles, white spatula master subtly spreads "product" and sees to it that everything was clean. In the photo, just, something noticed chooses.

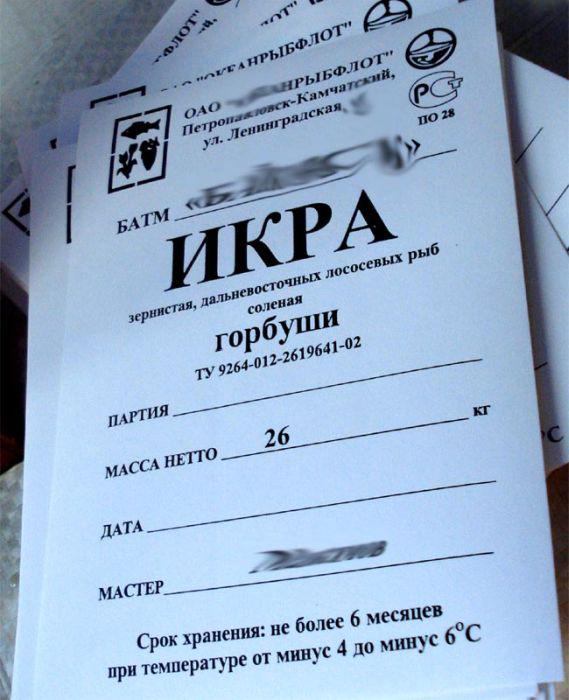

Each tank container label with the producer, type of eggs, the date of manufacture, etc.

Installation of lead seals on each kuboteynere.

Well, that's actually the way it is ...

PLEASANT of appetite !!!

And the salmon, which is not caught, carries its caviar in the river - spawning offspring to continue ... and dies, carpeting Berg and braids their bodies ...

From

Perhaps, for many a jar of red caviar is associated with the holiday.

And in actual fact, before you get to your desk, around the feast of caviar no no ... quite the contrary - it is hard work.

With the application a few photos I will try to show briefly.

The bulk of all red caviar produced in Kamchatka and Sakhalin (the Pacific Ocean, the Bering Sea and Sea of Okhotsk). When Putin begins, to the places of fishing fleet rushes. In my particular case, the process is shown in the two-way processing vessel BATM (large standalone freezer trawler), who took the fish with fixed nets on the west coast of Kamchatka.

With fixed nets fishermen catch to supply the miners transceiver processing vessel.

Hoppers in clerk. Hence fish fed by gravity to the line cutting.

Line cutting. There shkeryat fish - eggs put in blue paramushki on top, ulcer in one hole, the fish in another. Gutted fish on the tray flows in the plant on the deck below, guts overboard. The factory gutted washed, sized, frost and packed in containers. Finish in the freezer hold.

Sort yastiks caviar species. Mix the eggs of different fish - an unacceptable crime.

Here and wash yastiks seawater.

At this stage, the eggs are separated from yastiks - rattle. The machine is called - Butare. To make it cleaner - use two grohotki.

Division caviar falls on an inclined gauze. Here, too, are the film pieces and all sorts of rubbish.

Otgrohotannuyu caviar is salted in brine (brine). Simultaneously, salting, caviar and laundered here. The ratio of eggs / brine - 1/3. Salt to saturation calf about 4%. By the time - about 10-20 minutes, depending on the "fortress" of brine.

Incidentally, the brine is boiled here on the deck in such "small saucepan».

After prosolki caviar is packed by a small basket which lay in a centrifuge, where 10-15 minutes of "spin" does spawn almost dry and it gets to the table wizard to add a stretch of oil and preservatives. Here the last control of the purity and quality backlit table below.

Packing table with bottom illumination in order to shine through the thickness of the eggs and were well marked "foreign body" (pieces of blood, film, etc.). In the already salted and ottsentrifuzhennuyu caviar on this table wizard adds and mixes vegetable oil and antiseptics. In the past (before 2010) used methenamine and sorbic acid Now some more "useful" stuff. Before packing in bottles, white spatula master subtly spreads "product" and sees to it that everything was clean. In the photo, just, something noticed chooses.

Each tank container label with the producer, type of eggs, the date of manufacture, etc.

Installation of lead seals on each kuboteynere.

Well, that's actually the way it is ...

PLEASANT of appetite !!!

And the salmon, which is not caught, carries its caviar in the river - spawning offspring to continue ... and dies, carpeting Berg and braids their bodies ...

From